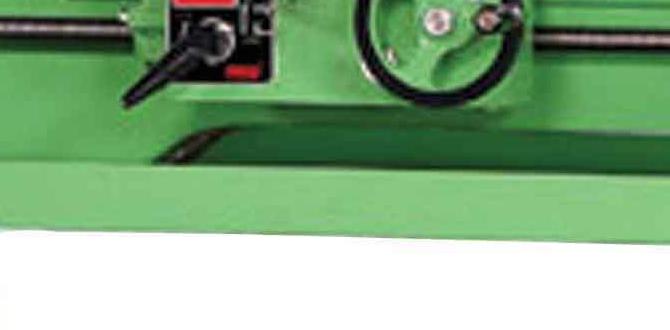

Have you ever wondered how metal parts are made? Many of them come from a machine called a lathe. This awesome tool spins metal and helps shape it. But did you know that using the right coolant can make a big difference?

A lathe training course can teach you how to use this powerful machine. It’s not just about turning metal; it’s also about taking care of it. Metal lathe coolant is important because it keeps the machine running smoothly. It reduces heat and makes cutting easier.

Imagine working on a lathe and feeling the heat rise. If you don’t cool it down, the metal might break. That’s why learning about coolant in a lathe training course is so important. You can learn how to keep your projects safe and fun!

So, are you ready to dive into a world of spinning metal and cool liquids? Let’s explore how to get started with your lathe training and why coolant matters!

Lathe Training Course: Master Metal Lathe Coolant Techniques

Lathe Training Course: Metal Lathe Coolant

Learn the importance of coolant in metal lathing. Coolant helps keep the lathe running smoothly by cooling the tools and workpieces. It also prevents rust and improves the cut’s quality. Did you know that using the right coolant can lengthen the life of your tools? In a lathe training course, you’ll discover different types of coolants and how to use them effectively. Proper coolant use enhances safety and performance, making your projects more successful!Understanding Metal Lathe Coolant

Definition and importance of coolant in metal lathing. Different types of metal lathe coolants and their properties.Coolant is a liquid used during metal lathing to keep the machine cool. It’s like a refreshing drink for your lathe to prevent it from overheating. Without coolant, things can get pretty hot, causing damage and making parts break. There are various types of coolants, like oils and water-based solutions, each with its own special qualities. For example, oils might be better for lubrication, while water-based coolants offer easy cleanup.

| Type of Coolant | Properties |

|---|---|

| Oil-Based | Great for lubrication; helps reduce friction. |

| Water-Based | Easy to clean; usually cheaper. |

| Synthetic | Mix of water and oil; provides benefits of both. |

Choosing the right coolant is key. Remember, a happy lathe means smooth turning! So, don’t let it sweat—give it a refreshing splash of coolant!

Benefits of Using Coolant in Lathe Operations

Enhanced tool life and performance. Improved surface finish and precision in machining.Using coolant during lathe operations can be a game-changer! First, it boosts tool life and performance, allowing your tools to last longer and work better. Think of it as giving them a refreshing spa day. Second, it helps achieve a smoother surface finish and precise cuts. You won’t have that ‘oops’ moment when your parts don’t fit together. It’s like using a magic potion for more efficient and cleaner machining!

| Benefit | Explanation |

|---|---|

| Enhanced Tool Life | Coolant reduces friction, helping tools last longer. |

| Improved Surface Finish | It aids in achieving a smoother cut and precision. |

Choosing the Right Coolant for Your Lathe Training Course

Factors to consider when selecting coolant. Comparison of various coolant options.Choosing the right coolant is essential for your lathe training course. But what should you consider? Here are some key factors:

- Cooling Effectiveness: The coolant needs to cool the metal during cutting.

- Lubrication: Good lubricants help reduce friction, making cuts easier.

- Compatibility: Ensure the coolant works well with your machine and materials.

- Cost: Compare prices to find a suitable option for your budget.

There are various types of coolants available:

- Water-Based Coolants: Affordable and effective, but may need more frequent changes.

- Oil-Based Coolants: Provides excellent lubrication but can be more expensive.

- Synthetic Coolants: Good for long-term use and eco-friendly.

What is the best coolant for a lathe?

The best coolant depends on your specific needs, but oil-based options often offer superior lubrication and cooling.Application Techniques for Metal Lathe Coolant

Methods of applying coolant during machining. Best practices for optimal coolant usage.Coolant is vital for metal lathe work. It helps keep the tools cool and prevents damage. Here are some methods to apply coolant while machining:

- Use a misting system for an even spray.

- Apply coolant directly with a brush for precision.

- Flood coolant provides thorough coverage for larger jobs.

To make the best use of coolant:

- Choose the right type for your material.

- Monitor levels to prevent running dry.

- Keep your workspace clean to avoid contamination.

Using coolant properly can extend tool life and improve finishes.

What are effective methods for using metal lathe coolant?

Effective methods include misting systems, direct application, and flood coolant for consistent cooling.

Safety Considerations When Working with Coolant

Hazardous properties of certain coolants. Personal protective equipment (PPE) and safety measures.Coolant can be a slippery subject, especially when safety is at stake. Some coolants contain hazardous properties that can make you go “uh-oh!” For instance, certain coolants may irritate your skin or eyes. To stay safe, wearing your Personal Protective Equipment (PPE) like gloves and goggles is a must. Always handle coolant with care! After all, you don’t want to mix up your toolbox with a soap factory, right? Here’s a quick look at some safety measures:

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Gloves, goggles, and aprons protect you from nasty spills. |

| Proper Ventilation | Ensure good airflow to keep harmful fumes away. |

| Read Labels | Knowing what’s in your coolant helps you avoid surprises. |

With these simple steps, you can make coolant work in your favor, not against you!

Common Mistakes to Avoid in Coolant Usage

Overuse and underuse of coolant. Ignoring cooling system maintenance.Using coolant is important for keeping machines cool and working well. However, many people make mistakes with coolant. Here are some common errors to avoid:

- Overusing coolant: Too much coolant can cause a mess and block the machine parts. This can lead to more problems.

- Underusing coolant: Not enough coolant can cause overheating and serious damage to the machine.

- Ignoring maintenance: If you skip checking the cooling system, it might stop working or even break down. Regular care keeps it running smoothly.

What happens if coolant is used incorrectly?

Incorrect coolant use can lead to machine breakdowns, higher costs, and unsafe working conditions.

Integrating Coolant Training into Your Lathe Course Curriculum

Suggested modules and topics for effective training. Importance of handson practice with coolant application.Effective lathe training should include rich modules on coolant use. Relevant topics might cover coolant types, application techniques, and maintenance practices. Hands-on practice is essential, allowing students to apply what they learn. This practical experience deepens understanding and builds skills. Consider incorporating these suggested modules:

- Understanding Coolant Functions

- Safe Handling and Disposal

- Coolant Application Techniques

- Regular Maintenance Practices

Why is hands-on practice with coolant important?

Hand-on practice allows students to experience coolant use firsthand. It helps them understand its impact on machining quality and safety. Engaging directly with tools builds confidence and competence.

Latest Trends and Innovations in Metal Lathe Coolants

Environmentally friendly coolant solutions. Technological advancements in coolant formulation.Coolants are changing faster than a wizard at a magic show! Today, many companies prefer environmentally friendly coolant solutions. These coolants are made from natural ingredients and help keep our planet smiling. Then, there’s amazing technology behind coolant formulas. They use new methods to improve cooling and reduce waste. It’s like giving metal lathes a refreshing drink while saving the world!

| Coolant Type | Benefits |

|---|---|

| Biodegradable Coolants | Easy on the environment |

| Synthetic Coolants | Great for high-tech machining |

Resources for Further Learning

Recommended books, online courses, and organizations. Forums and communities for lathe training and coolant discussions.Learning about lathes can be exciting! Here are some great resources to explore:

- Books: Look for titles like “The Lathe Book” for solid tips.

- Online Courses: Websites like Udemy offer courses on using a metal lathe.

- Organizations: Check out local maker spaces for hands-on experience.

Joining forums and communities is also helpful. You can ask questions and share ideas about lathe training and coolant. Connecting with others makes learning fun!

What are useful forums for lathe training?

You can find many helpful forums. Two great ones are Machinists’ Forum and Practical Machinist. These places let you chat with experts and other learners.

Conclusion

In conclusion, a lathe training course teaches you how to use a metal lathe effectively. You learn about different tools, techniques, and the importance of coolant. Coolant helps keep the lathe and metal pieces cool while you work. To improve your skills, consider taking a course or reading more about metalworking. Let’s get started on your journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Coolant:Sure! Here are five questions about a lathe training course that focuses on metal lathe coolant: 1. What is metal lathe coolant? Metal lathe coolant is a special liquid that helps cool down the metal when we cut it. 2. Why do we need coolant? We need coolant to keep the metal from getting too hot and to help make a smooth cut. 3. How do we add coolant to the lathe? You can add coolant by using a special tank or a spray system that fits onto the lathe. 4. Is coolant safe to touch? Some coolants can be safe, but it’s best to wash your hands after using them, just to be safe. 5. Can you use water as coolant? Water can be used as coolant, but special liquid is usually better because it works faster and prevents rust.

Sure! Just let me know the question you want me to answer.

What Types Of Coolant Are Commonly Used In Metal Lathe Operations, And How Do They Differ In Application And Performance?In metal lathe work, we use different coolants. Water-based coolants are often used because they are cheap and cool things down well. Oil-based coolants can help reduce friction, which makes cutting easier. Some coolants mix water and oil, getting the benefits of both. Each type works best in different situations, depending on the metal and the task we’re doing.

How Does The Use Of Coolant Improve The Machining Process On A Metal Lathe, Particularly In Terms Of Tool Life And Surface Finish?Using coolant in a metal lathe helps keep things cool while we work. This prevents the tools from getting too hot, which helps them last longer. It also makes the surface of the metal smoother. When tools stay cool and sharp, we get better results. So, coolant really helps us make our projects look nice and last longer!

What Safety Precautions Should Be Taken When Handling And Mixing Lathe Coolant During Training Sessions?When you handle lathe coolant, always wear gloves and goggles to protect your skin and eyes. Make sure you work in a well-ventilated area to avoid breathing in any harmful fumes. Always read the label on the coolant container for safety instructions. If you spill any coolant, clean it up right away to prevent slipping. Finally, wash your hands thoroughly after working with it.

How Can Participants In A Lathe Training Course Effectively Manage Coolant Disposal And Environmental Considerations?To manage coolant disposal, you should follow safe rules. First, always use a container to catch the used coolant. You can’t just dump it anywhere. Next, check if your local area has a special place for disposing of it safely. This helps keep our Earth clean and safe for everyone!

What Are The Key Factors To Consider When Selecting The Appropriate Coolant For Specific Metals Being Machined On A Lathe?When picking a coolant for metal cutting, we need to consider a few important things. First, think about the type of metal you’re working with, like aluminum or steel. Some coolants work better with certain metals. Next, check if the coolant helps keep the metal and tools from getting too hot. Finally, make sure the coolant is safe for us and easy to clean up.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about a lathe training course that focuses on metal lathe coolant: 1. What is metal lathe coolant? Metal lathe coolant is a special liquid that helps cool down the metal when we cut it. 2. Why do we need coolant? We need coolant to keep the metal from getting too hot and to help make a smooth cut. 3. How do we add coolant to the lathe? You can add coolant by using a special tank or a spray system that fits onto the lathe. 4. Is coolant safe to touch? Some coolants can be safe, but it’s best to wash your hands after using them, just to be safe. 5. Can you use water as coolant? Water can be used as coolant, but special liquid is usually better because it works faster and prevents rust.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Coolant Are Commonly Used In Metal Lathe Operations, And How Do They Differ In Application And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe work, we use different coolants. Water-based coolants are often used because they are cheap and cool things down well. Oil-based coolants can help reduce friction, which makes cutting easier. Some coolants mix water and oil, getting the benefits of both. Each type works best in different situations, depending on the metal and the task we’re doing.”}},{“@type”: “Question”,”name”: “How Does The Use Of Coolant Improve The Machining Process On A Metal Lathe, Particularly In Terms Of Tool Life And Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using coolant in a metal lathe helps keep things cool while we work. This prevents the tools from getting too hot, which helps them last longer. It also makes the surface of the metal smoother. When tools stay cool and sharp, we get better results. So, coolant really helps us make our projects look nice and last longer!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Handling And Mixing Lathe Coolant During Training Sessions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you handle lathe coolant, always wear gloves and goggles to protect your skin and eyes. Make sure you work in a well-ventilated area to avoid breathing in any harmful fumes. Always read the label on the coolant container for safety instructions. If you spill any coolant, clean it up right away to prevent slipping. Finally, wash your hands thoroughly after working with it.”}},{“@type”: “Question”,”name”: “How Can Participants In A Lathe Training Course Effectively Manage Coolant Disposal And Environmental Considerations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To manage coolant disposal, you should follow safe rules. First, always use a container to catch the used coolant. You can’t just dump it anywhere. Next, check if your local area has a special place for disposing of it safely. This helps keep our Earth clean and safe for everyone!”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting The Appropriate Coolant For Specific Metals Being Machined On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a coolant for metal cutting, we need to consider a few important things. First, think about the type of metal you’re working with, like aluminum or steel. Some coolants work better with certain metals. Next, check if the coolant helps keep the metal and tools from getting too hot. Finally, make sure the coolant is safe for us and easy to clean up.”}}]}