Have you ever wanted to create something amazing with metal? Learning how to use a metal lathe is a fantastic skill! A lathe training course can open new doors in the world of machining.

Imagine being able to shape metal into anything you desire. From simple parts to intricate designs, the possibilities are endless. One important part of mastering a lathe is the cross slide. This tool helps you move the cutting tool accurately, ensuring your projects come out just right.

Did you know that using a metal lathe properly can save time and make your work more enjoyable? Many beginners feel unsure about handling this powerful machine. But with the right training, you can gain confidence and learn plenty of tips.

Whether you’re a hobbyist or a future career machinist, a lathe training course is for you! Let’s explore the exciting journey of working with metal lathes and discover what makes the cross slide so essential. Are you ready to dive into this hands-on adventure?

Lathe Training Course: Master Metal Lathe Cross Slide Techniques

Lathe Training Course: Metal Lathe Cross Slide

Taking a lathe training course can open doors to exciting woodworking and metalworking projects. You’ll learn how to use the metal lathe, especially the cross slide, which helps move the tool with precision. Ever wondered how professionals achieve such accurate cuts? With hands-on practice, you’ll master this skill. Plus, understanding its mechanics can boost your confidence in the workshop. Sign up today, and turn your ideas into reality!Understanding the Basics of Metal Lathes

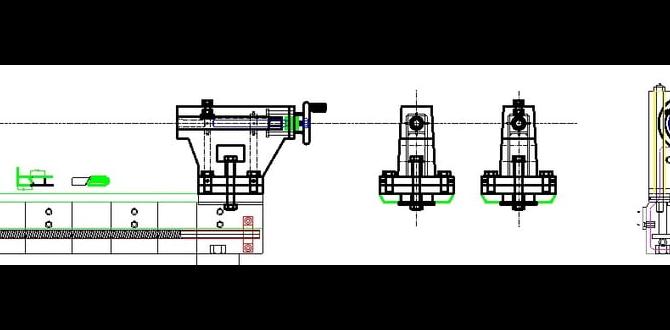

Definition and components of a metal lathe. Importance of lathe machines in metalworking.A metal lathe is a machine that helps shape metal into useful parts. Think of it as a giant pencil sharpener, but instead of wood, it works with metal! Key parts include the bed, where everything sits, and the cross slide, which moves tools side to side. These machines are super important in metalworking. They let workers create everything from gears to delicate airplane parts. Without lathes, we might still be using rock tools!

| Component | Function |

|---|---|

| Bed | Support for the entire machine |

| Cross Slide | Moves the cutting tool |

| Tailstock | Holds and supports the workpiece |

Key Features of the Cross Slide in Metal Lathes

Functionality and mechanics of the cross slide. Common materials and designs used in cross slides.The cross slide is a key part of metal lathes, like the best sidekick in an action movie! It allows the cutting tool to move side to side, making precise cuts. This movement is crucial for shaping the metal. The main materials used for cross slides are sturdy metals and heavy-duty plastics. These materials keep everything strong and efficient, just like a superhero’s armor!

| Material | Benefits |

|---|---|

| Steel | Strong and durable |

| Cast Iron | Good vibration dampening |

| Aluminum | Lightweight and easy to move |

| Heavy-duty Plastics | Corrosion-resistant |

Designs may vary, but the goal remains the same: delivering precision. So next time you see a lathe, remember its unsung hero—the cross slide!

Benefits of Taking a Lathe Training Course

Skill development and career opportunities in machining. Handson experience and access to professional instructors.Taking a lathe training course opens up many exciting doors! First off, you can learn amazing skills that make you a machining superstar. Who knew turning metal could be so fun? Plus, you’ll gain hands-on experience that makes you feel like a wizard in the workshop. And guess what? Professional instructors will guide you, so you can avoid the “oops” moments. With this training, you’re not just learning; you’re planting seeds for career opportunities in machining. Here’s a quick look at the perks:

| Benefits | Description |

|---|---|

| Skill Development | Learn essential machining skills |

| Hands-on Experience | Practice on real lathes |

| Expert Guidance | Access to skilled instructors |

| Career Opportunities | Tons of jobs available! |

So, if you’re thinking about joining a lathe training course, just remember: it’s a journey to become a metal-magic maker!

Choosing the Right Lathe Training Course

Factors to consider: accreditation, duration, and cost. Recommendations for reputable training institutions.Picking the right lathe training course can be tricky. Consider these key factors:

- Accreditation: Make sure the school is recognized for quality.

- Duration: Check how long the course lasts. A short course may help you learn quickly.

- Cost: Compare prices to find a good match for your budget.

Look for institutions like trade schools or community colleges. They often have great programs to help you master the metal lathe cross slide.

What should I look for in a lathe course?

Consider accreditation, which shows the program’s quality. Look at the duration to see if it fits your schedule. Lastly, check the cost to find a course that won’t break the bank.

Practical Applications of Metal Lathe and Cross Slide Skills

Industry applications and job roles utilizing cross slide techniques. Examples of projects and components that can be created.Metal lathes and cross slide skills open doors to many cool jobs! From making tiny parts for computers to crafting large machinery, these skills fit everywhere. Workers in fields like manufacturing and automotive use precision lathe techniques daily. You can create gear shafts, custom fittings, and even decorative pieces. Did you know that a well-trained lathe operator can double a company’s production? Now that’s impressive! Let’s take a peek at some examples:

| Project Type | Description |

|---|---|

| Gear Shafts | Critical for machines to function smoothly. |

| Custom Fittings | Perfect for unique assembly needs. |

| Decorative Parts | Adds flair to everyday objects. |

Common Challenges and Troubleshooting in Cross Slide Operation

Typical problems faced when using the cross slide. Solutions and tips for efficient operation.Using the cross slide can be tricky at times. Here are some common problems you might face:

- Stuck slides due to dirt or rust.

- Incorrect settings leading to mistakes.

- Difficulties adjusting the tool position.

To solve these issues:

- Keep the slide clean and well-oiled.

- Adjust settings slowly and double-check.

- Practice adjusting the tool gently.

With practice, these tips can help you operate the cross slide more smoothly!

What are common issues with cross slide operation?

Common issues include stuck slides, incorrect settings, and tool position difficulties.

How can I troubleshoot cross slide problems?

Regular cleaning, careful adjustments, and practice can solve most cross slide issues.

Advanced Techniques for Mastering the Cross Slide

Tips for precision and accuracy in machining. Utilizing advanced tools and accessories for enhanced performance.To really get the most out of your metal lathe’s cross slide, precision is key. One tip is to always make sure your measurements are spot-on—think of it like measuring for a new pair of shoes: too big or too small just won’t do! Another trick? Use advanced tools and accessories like DROs (Digital Readouts) to boost performance. They help you cut those pesky errors down to size. Also, remember to keep your tools sharp; dull tools are like trying to eat spaghetti with a spoon—frustrating and messy!

| Technique | Description |

|---|---|

| Measurements | Always double-check your dimensions for accuracy. |

| DROs | Use Digital Readouts for better performance. |

| Sharp Tools | Keep tools sharp to avoid mistakes! |

Conclusion

In conclusion, a lathe training course on the metal lathe cross slide teaches you essential skills. You learn how to set up and control the cross slide for precise machining. Practicing these skills helps you make better projects. We encourage you to explore different courses and hands-on practice. Start your journey in metalworking and discover the fun of creating!FAQs

Certainly! Here Are Five Questions Related To A Lathe Training Course Focused On The Metal Lathe Cross Slide:Sure! Here are five questions about a lathe training course with a focus on the cross slide of a metal lathe: 1. What does the cross slide on a lathe do? The cross slide helps move the tool side to side. This makes it easier to shape the metal. 2. How do you adjust the cross slide? You can adjust it by turning a handle. This moves the tool closer or farther away from the metal. 3. Why is the cross slide important? The cross slide helps make precise cuts and shapes on the metal. It is key for good work. 4. Can you use the cross slide for different projects? Yes! You can use it for many projects, big and small. It is very useful. 5. What should you be careful about when using the cross slide? Always be careful not to move it too fast. Go slow to make sure you get good results.

Sure! Please tell me the question you’d like me to answer.

What Are The Key Components Of A Metal Lathe Cross Slide, And How Do They Function Together In Machining Operations?A metal lathe cross slide has several important parts. These include the cross slide itself, the screw, and the handle. The cross slide moves left and right to position the cutting tool. Turning the handle makes the screw rotate, which helps the cross slide move smoothly. Together, these parts help carve shapes into the metal as it spins.

How Do You Properly Adjust The Cross Slide To Achieve Precise Cutting Tolerances During Metalworking?To adjust the cross slide, first, make sure your machine is turned off. Next, loosen the handle that holds the slide in place. Then, move the slide carefully to where you want it. Tighten the handle again to keep it steady. Finally, you can test it by making a small cut, checking if it’s just right!

What Safety Precautions Should Be Taken When Operating The Cross Slide On A Metal Lathe?When you use the cross slide on a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from the moving parts to avoid injury. Always check that there are no loose tools or materials nearby. Make sure to follow the machine’s instructions carefully. Finally, never use the lathe when you are distracted or tired.

Can You Explain The Process For Troubleshooting Common Issues That Arise With The Cross Slide During Machining?To troubleshoot the cross slide during machining, we start by checking if it moves smoothly. If it sticks, we clean it and add some oil. Next, we look for any loose screws or parts. Tighten anything that feels loose. Finally, we test it again to make sure everything works well.

What Types Of Projects Or Tasks Are Best Suited For Utilizing The Cross Slide Feature On A Metal Lathe?You can use the cross slide feature on a metal lathe for many tasks. It helps us cut shapes like squares or grooves. We can also make precise cuts on small parts. If we want to create holes at an angle, the cross slide is very useful too. This feature makes our work more accurate and easier!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To A Lathe Training Course Focused On The Metal Lathe Cross Slide:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about a lathe training course with a focus on the cross slide of a metal lathe: 1. What does the cross slide on a lathe do? The cross slide helps move the tool side to side. This makes it easier to shape the metal. 2. How do you adjust the cross slide? You can adjust it by turning a handle. This moves the tool closer or farther away from the metal. 3. Why is the cross slide important? The cross slide helps make precise cuts and shapes on the metal. It is key for good work. 4. Can you use the cross slide for different projects? Yes! You can use it for many projects, big and small. It is very useful. 5. What should you be careful about when using the cross slide? Always be careful not to move it too fast. Go slow to make sure you get good results.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Cross Slide, And How Do They Function Together In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe cross slide has several important parts. These include the cross slide itself, the screw, and the handle. The cross slide moves left and right to position the cutting tool. Turning the handle makes the screw rotate, which helps the cross slide move smoothly. Together, these parts help carve shapes into the metal as it spins.”}},{“@type”: “Question”,”name”: “How Do You Properly Adjust The Cross Slide To Achieve Precise Cutting Tolerances During Metalworking?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the cross slide, first, make sure your machine is turned off. Next, loosen the handle that holds the slide in place. Then, move the slide carefully to where you want it. Tighten the handle again to keep it steady. Finally, you can test it by making a small cut, checking if it’s just right!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating The Cross Slide On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use the cross slide on a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from the moving parts to avoid injury. Always check that there are no loose tools or materials nearby. Make sure to follow the machine’s instructions carefully. Finally, never use the lathe when you are distracted or tired.”}},{“@type”: “Question”,”name”: “Can You Explain The Process For Troubleshooting Common Issues That Arise With The Cross Slide During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot the cross slide during machining, we start by checking if it moves smoothly. If it sticks, we clean it and add some oil. Next, we look for any loose screws or parts. Tighten anything that feels loose. Finally, we test it again to make sure everything works well.”}},{“@type”: “Question”,”name”: “What Types Of Projects Or Tasks Are Best Suited For Utilizing The Cross Slide Feature On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use the cross slide feature on a metal lathe for many tasks. It helps us cut shapes like squares or grooves. We can also make precise cuts on small parts. If we want to create holes at an angle, the cross slide is very useful too. This feature makes our work more accurate and easier!”}}]}