Have you ever wondered how a simple piece of metal can be transformed into something amazing? The magic often happens on a metal lathe. In a lathe training course, you can learn just how that process works.

Using a metal lathe is like crafting your own model car or toy. You start with a block of metal, and with the right tools, you shape it into something unique. But there’s one critical part of working safely on a lathe: the foot brake.

Imagine it’s your first day in class. You approach the metal lathe, filled with excitement and a hint of fear. Suddenly, you remember the importance of that foot brake. It can stop the lathe quickly, keeping everyone safe. Isn’t it cool how a small feature can have such a big impact?

In this article, we will explore why a lathe training course teaches you about the metal lathe foot brake. You’ll find tips that help you feel confident and ready to create your own projects.

Comprehensive Lathe Training Course: Metal Lathe Foot Brake

Lathe Training Course: Mastering the Metal Lathe Foot Brake

A lathe training course teaches important skills for using metal lathes safely. One key aspect is the foot brake, which stops the machine quickly. Understanding how to use the foot brake can prevent accidents. Have you ever wondered how heavy machinery works? Learning about it can be exciting! In this course, you’ll also discover proper techniques and maintenance tips. With the right training, you can become a confident lathe operator.The Role of the Foot Brake in Metal Lathes

Definition and functionality of the foot brake. Benefits of using a foot brake for precision and control.The foot brake on a metal lathe is a magic little pedal that helps you stop the machine smoothly. Imagine you’re driving a car; you wouldn’t want to slam the brakes, right? With a foot brake, you have better precision and control while working. This feature lets you stop the lathe quickly without messing up your project. Plus, it keeps your hands free for switching tools or giving victory dances when you make something awesome!

| Benefit | Description |

|---|---|

| Precision | Stops the lathe exactly when needed, avoiding errors. |

| Control | Helps manage speed and stops smoothly for better results. |

Essentials of a Lathe Training Course

Key topics covered in basic lathe training. Importance of handson experience in training.In a lathe training course, students explore key topics like safety protocols, tool selection, and basic machining techniques. Hands-on experience is vital; it’s where learning comes alive! Practicing on real machines helps students understand how to use the foot brake effectively. Imagine trying to ride a bicycle without learning to brake—you’d end up in a bush! Lastly, a fun fact: 70% of trainees who get hands-on practice feel more confident afterwards.

| Key Topics | Importance |

|---|---|

| Machine Operation | Practice makes perfect! |

| Safety Measures | Better safe than in the bush! |

| Feature Functions | Know your tools! |

Types of Lathe Training Courses Available

Online vs. inperson training courses. Comparison of beginner, intermediate, and advanced levels.Many options exist for learning about lathes. You can choose online courses, where you fit lessons into your schedule, or in-person classes for hands-on training with an expert. Beginner courses start with the basics, while intermediate and advanced classes dive deeper into skills. It’s like moving from baby steps to a dance competition! Here’s a quick look:

| Course Level | Training Type |

|---|---|

| Beginner | Online/In-person |

| Intermediate | Online/In-person |

| Advanced | Online/In-person |

Choosing the right course can make a big difference. Remember, even the most skilled lathe operators started out as beginners—they didn’t just pop out of the tool box!

Choosing the Right Lathe Training Course

Factors to consider when selecting a course. Recommendations for reputable training providers.Picking a lathe training course is important for learning. Here are key factors to think about:

- Check if the course teaches metal lathe usage.

- Look for courses that include safety features, like a foot brake.

- Find out if the instructors are experienced.

- Read reviews from former students.

Consider these reputable providers:

- Local community colleges

- Technical training centers

- Online courses with good ratings

These tips will help you choose the right training for your needs!

What should I look for in a lathe training course?

Look for quality instructors, hands-on practice, and safety focus. Good courses offer real-life skills and tools.

Where can I find trusted lathe training providers?

Check community colleges, technical schools, or respected online platforms. They often have great programs for lathe training.

Skills Acquired Through Lathe Training

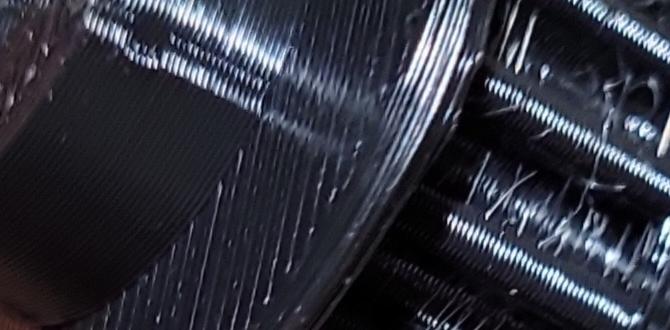

Essential skills developed during training. Realworld applications of lathe skills in metalworking.When learning lathe skills, you gain many important abilities. You can learn how to use machines safely. With practice, you will master precise measurements. These skills are useful in many jobs in metalworking. You will often see lathe skills applied to:

- Making parts for cars

- Creating tools and fixtures

- Building industrial machines

Each application benefits from accuracy and creativity, making lathe training truly valuable.

What skills do you learn in a lathe training course?

In a lathe training course, you learn to operate machines, measure accurately, and create different metal shapes. These skills are useful in several jobs.

Common Challenges in Lathe Training

Obstacles faced by trainees and how to overcome them. Tips for effective learning and practice.Learning how to use a lathe can be tricky. Many students face challenges like understanding machine parts and following safety rules. It’s important to practice often to gain confidence. Asking questions will help clear confusion. Here are some tips for success:

- Take your time to learn each part of the lathe.

- Focus on safety, especially using the foot brake properly.

- Practice simple tasks before moving to complex projects.

Remember, persistence is key! Each mistake is a chance to learn and improve.

What are common issues faced during lathe training?

Many trainees struggle with safety, understanding machine parts, and mastering techniques. Regular practice and asking for help from instructors can make a big difference.

Real-Life Success Stories from Lathe Training Graduates

Case studies of individuals who benefited from training. Industry impacts of skilled lathe operators.Many lathe training graduates have turned their skills into success stories. For example, one student started a metalworking shop after graduation. They now create custom parts for local businesses. This success proves how important skilled lathe operators are in our industry. Their work helps keep many companies running smoothly.

- Real-world skills gained from training.

- Supports local economies by providing jobs.

- Increases productivity in various sectors.

How do lathe training programs change lives?

Lathe training programs provide hands-on skills. Graduates find better job opportunities and create their own businesses. This helps them earn more money and gain confidence. Their achievements inspire others to pursue similar paths.

Future Trends in Lathe Training and Technology

Innovations in lathe technology and training methods. Predictions for the future of metalworking and lathe training courses.New ideas are changing how we learn and use lathes. Smart technology makes machines easier and safer. Virtual reality helps students practice in safe settings. Future metalworking will be faster and smarter. Predictions show that more people will learn these skills online. This makes training available to everyone. New training methods will help create experts in the field.

- Using virtual tools for better learning.

- Rapid advancements in machine design.

- Greater focus on safety training.

- More online courses available.

What are the future innovations in lathe training?

Future innovations in lathe training include advanced simulations, interactive learning platforms, and smart machine technology.

Conclusion

In conclusion, a lathe training course teaches you essential skills for using a metal lathe safely. Knowing how to use a foot brake helps you control the machine better. You can create many projects with practice. Now, consider enrolling in a course or reading more about lathes. Start your journey into metalworking today!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathes With A Foot Brake:Sure! Here are answers to five questions about the lathe training course. 1. **What is a lathe?** A lathe is a machine that shapes metal. It can spin metal pieces to cut or smooth them. 2. **What will we learn in the course?** You will learn how to use a lathe safely. We will practice cutting shapes and finishing the metal. 3. **Why is having a foot brake important?** A foot brake helps you stop the lathe quickly. It keeps you safe while you work. 4. **How long is the training course?** The course lasts for a few days. Each day, we will have fun learning new skills. 5. **What do I need to bring?** Just bring yourself and a notebook. We will provide tools and machines for you to use.

Sure! Please give me the question you want me to answer.

What Are The Safety Benefits Of Using A Foot Brake On A Metal Lathe During Operation?Using a foot brake on a metal lathe helps keep you safe while working. It lets you quickly stop the machine when needed. This can prevent accidents if something goes wrong. You can keep your hands free for other tasks, making it safer to work. Overall, the foot brake helps you control the machine better and stay out of danger.

How Do You Properly Adjust The Foot Brake On A Metal Lathe To Ensure Optimal Performance?To adjust the foot brake on a metal lathe, first, find the brake pedal. You should check if it feels too loose or too tight. If it’s loose, you can tighten the adjustment screw until it feels just right. If it’s too tight, loosen the screw a little. Always test the brake to make sure it works well and stops the machine safely.

What Are The Common Troubleshooting Steps If The Foot Brake On A Metal Lathe Is Not Functioning Correctly?If the foot brake on a metal lathe isn’t working, we can try a few things. First, check if any parts are loose or damaged. Next, see if the brake pedal is stuck or getting stuck on something. We should also look at the connections to make sure they are clean and secure. If it still doesn’t work, it might be best to ask an adult or a professional for help.

In What Scenarios Would You Prioritize The Use Of A Foot Brake Over Other Stop Mechanisms On A Metal Lathe?You should use the foot brake on a metal lathe when you need to stop quickly. It helps you stop the machine fast without moving your hands. If your hands are busy or you need to keep your eyes on the work, the foot brake is great. It’s also helpful when you want to stop more safely while working.

How Can Foot Brake Operation Enhance Productivity And Precision When Working On A Metal Lathe During A Training Course?Using the foot brake on a metal lathe helps you stop the machine quickly. This means you can change your work faster. When you stop exactly where you want, you make better cuts. This makes your work look nicer and helps you finish on time. Overall, it keeps everything safe and efficient while you learn!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathes With A Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are answers to five questions about the lathe training course. 1. **What is a lathe?** A lathe is a machine that shapes metal. It can spin metal pieces to cut or smooth them. 2. **What will we learn in the course?** You will learn how to use a lathe safely. We will practice cutting shapes and finishing the metal. 3. **Why is having a foot brake important?** A foot brake helps you stop the lathe quickly. It keeps you safe while you work. 4. **How long is the training course?** The course lasts for a few days. Each day, we will have fun learning new skills. 5. **What do I need to bring?** Just bring yourself and a notebook. We will provide tools and machines for you to use.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Safety Benefits Of Using A Foot Brake On A Metal Lathe During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a foot brake on a metal lathe helps keep you safe while working. It lets you quickly stop the machine when needed. This can prevent accidents if something goes wrong. You can keep your hands free for other tasks, making it safer to work. Overall, the foot brake helps you control the machine better and stay out of danger.”}},{“@type”: “Question”,”name”: “How Do You Properly Adjust The Foot Brake On A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the foot brake on a metal lathe, first, find the brake pedal. You should check if it feels too loose or too tight. If it’s loose, you can tighten the adjustment screw until it feels just right. If it’s too tight, loosen the screw a little. Always test the brake to make sure it works well and stops the machine safely.”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps If The Foot Brake On A Metal Lathe Is Not Functioning Correctly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the foot brake on a metal lathe isn’t working, we can try a few things. First, check if any parts are loose or damaged. Next, see if the brake pedal is stuck or getting stuck on something. We should also look at the connections to make sure they are clean and secure. If it still doesn’t work, it might be best to ask an adult or a professional for help.”}},{“@type”: “Question”,”name”: “In What Scenarios Would You Prioritize The Use Of A Foot Brake Over Other Stop Mechanisms On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use the foot brake on a metal lathe when you need to stop quickly. It helps you stop the machine fast without moving your hands. If your hands are busy or you need to keep your eyes on the work, the foot brake is great. It’s also helpful when you want to stop more safely while working.”}},{“@type”: “Question”,”name”: “How Can Foot Brake Operation Enhance Productivity And Precision When Working On A Metal Lathe During A Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the foot brake on a metal lathe helps you stop the machine quickly. This means you can change your work faster. When you stop exactly where you want, you make better cuts. This makes your work look nicer and helps you finish on time. Overall, it keeps everything safe and efficient while you learn!”}}]}