Have you ever seen a metal lathe in action? It’s fascinating to watch! With the right skills, anyone can learn to create amazing things using this tool. A lathe training course can help you master this craft.

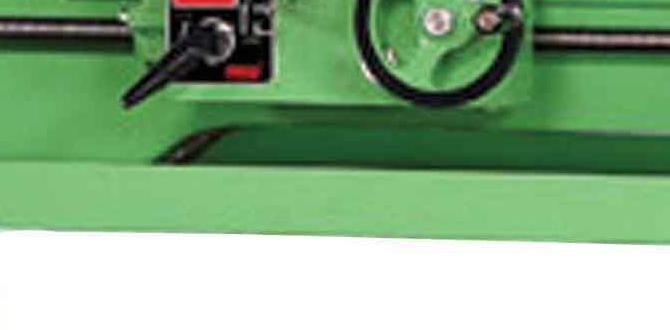

One key part of the lathe is the handwheel. This small tool lets you control the machine with precision. Understanding how to use the handwheel is essential for any beginner. Imagine making perfectly shaped pieces of metal with just a simple turn!

Whether you’re a hobbyist or want a career in machining, a lathe training course can open doors. It’s a fun way to gain confidence and learn a valuable skill. Are you ready to turn your ideas into reality?

Comprehensive Lathe Training Course: Mastering Metal Lathe Handwheel

Lathe Training Course: Metal Lathe Handwheel

A lathe training course teaches you how to use a metal lathe safely and effectively. You’ll discover the role of the handwheel, which helps you adjust the lathe’s movement easily. Did you know the handwheel can control speed and accuracy? Learning about this tool can spark your creativity and boost your skills. With practice, you can create amazing projects from metal. Isn’t it exciting to think about the possibilities?Understanding the Basics of Metal Lathes

Definition and purpose of a metal lathe. Key components of a metal lathe.A metal lathe is a machine that shapes metal. It spins the metal piece while cutting tools remove material. This helps create round, smooth shapes. The main parts of a metal lathe include:

- Headstock: The motor and gears are here, controlling the spindle.

- Tailstock: Supports the metal piece and can hold tools.

- Carriage: Moves along the lathe to control cutting tools.

- Bed: The main part that holds everything in place.

By knowing these parts and their functions, you can better understand how a metal lathe works!

What is the purpose of a metal lathe?

The purpose is to shape metal into desired forms for parts and tools. A lathe can create complex designs. It helps in manufacturing items like screws, gears, and more.

What are the key components of a metal lathe?

- Headstock: Contains the motor and operates the spindle.

- Tailstock: Holds tools and supports the workpiece.

- Carriage: Moves the cutting tools along the metal piece.

- Bed: The base that supports all parts of the lathe.

The Role of the Handwheel in Lathe Operation

Detailed functions of the handwheel in metal lathes. How to effectively use the handwheel for precision work.The handwheel on a metal lathe is important for controlling the tool’s movement. It helps in making precise adjustments. Here are some of its key functions:

- Fine control: The handwheel lets you move the cutting tool slowly and accurately.

- Depth adjustment: You can set how deep the tool cuts into the metal.

- Speed management: It helps you change speeds for different tasks.

To use the handwheel effectively, turn it gently. This will give you better results. Practice is key to mastering this tool. The more you use it, the better you’ll become.

What are the main advantages of using the handwheel?

The handwheel improves precision and control during lathe operations. It allows finer adjustments, which leads to better quality work.

Safety Protocols in Lathe Operation

Essential safety measures when operating a lathe. Common safety mistakes and how to avoid them.When using a lathe, safety is key. Always wear protective gear like goggles and gloves. Keep your workspace clean and organized. Never reach over the spinning parts. Here are some common mistakes to avoid:

- Not checking if tools are sharp.

- Ignoring safety guards.

- Working too quickly or carelessly.

Staying alert helps prevent accidents. Remember, safety first means a safer and smoother operation!

What are the safety measures when operating a lathe?

Essential safety measures include wearing protective gear, keeping the work area clean, and avoiding loose clothing.

How to avoid common safety mistakes?

Check tools regularly, use safety guards, and stay focused while working.

Hands-on Training: Practical Lab Sessions

Importance of handson experience in lathe workshops. Examples of practical exercises to reinforce learning.Getting hands-on in a workshop is like having a treasure map for learning. Practical lab sessions let students put theory into action. For example, making small parts on a metal lathe helps build confidence and skills. Exercises like shaping a cylinder or cutting threads are fun and effective. Plus, nothing beats the excitement of seeing your creation come to life!

| Exercise | Skill Developed |

|---|---|

| Shaping a Cylinder | Precision Control |

| Cutting Threads | Technical Skills |

| Making Simple Jigs | Problem Solving |

In the wise words of a famous lathe enthusiast, “Practice makes perfect, but have fun while you’re at it!” That’s the spirit of hands-on training!

Assessing Your Lathe Skill Level

Methods for evaluating proficiency in lathe operations. Tools and resources for selfassessment.Understanding your skills on a metal lathe is important. You can check how good you are in many ways. Here are some useful methods:

- Practice simple tasks like cutting basic shapes.

- Ask a friend or teacher for feedback on your work.

- Use a skill checklist to track your progress.

To help yourself, you can also use tools like videos and books. These can show you new techniques. Keep practicing and stay curious!

How do you evaluate lathe skills?

One way to evaluate your lathe skills is by measuring project accuracy. Strongly focus on quality finishes and precise dimensions. Regular self-assessment helps you grow as a lathe operator.

Continuing Education and Skill Advancement

Opportunities for ongoing learning in metal lathe operation. Professional organizations and resources for lathe operators.Learning doesn’t stop after basic training. Lathe operators can keep improving their skills. Many resources exist for those looking to learn more about metal lathe operation. Here are some ways to continue your education:

- Online courses: Websites often have courses for different skill levels.

- Workshops: Local trade schools may offer hands-on classes.

- Professional organizations: Joining groups can provide networking opportunities and resources.

Staying current with new techniques boosts job performance and safety. The right training can lead to new job opportunities.

What resources are available for lathe operators?

Operators can find many helpful tools and guidance. Books, online tutorials, and community forums are excellent places to start. These resources can sharpen your skills and build confidence in your work.

Conclusion

In summary, a lathe training course teaches you how to use a metal lathe, focusing on the handwheel for precision. You learn important skills for shaping metal and creating parts. Understanding these basics helps you work safely and confidently. If you’re interested, consider signing up for a course or finding tutorials online to practice more!FAQs

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Handwheel?When using a metal lathe with a handwheel, always wear safety goggles to protect your eyes. Keep your hair tied back and remove any loose clothing. Make sure your hands are clear of the spinning parts. Always check that tools and the workpiece are securely in place before you start. Lastly, never distract someone while they’re using the lathe.

How Do You Correctly Adjust The Handwheel For Precise Machining On A Metal Lathe?To adjust the handwheel on a metal lathe, first, you check the position of the tool. Turn the handwheel slowly to move the tool closer to the metal. You want to make tiny movements for precise cuts. If the tool is too far or too close, adjust the handwheel a little more. Always double-check your settings before starting the machine.

What Are The Common Issues That Can Arise When Using A Handwheel On A Metal Lathe, And How Can They Be Resolved?When using a handwheel on a metal lathe, you might face some problems. One issue is that the handwheel can feel too tight or hard to turn. You can fix this by checking for dirt or oil that needs cleaning. Another problem is if the tool isn’t moving smoothly. You can solve this by making sure everything is lined up correctly and lubricated. Always ask for help if you’re unsure!

How Does The Handwheel Mechanism Affect The Overall Accuracy And Efficiency Of Metal Lathe Operations?The handwheel mechanism helps you control the metal lathe better. When you turn the handwheel, you can move the tool precisely. This makes your cuts more accurate. If you use the handwheel carefully, you will finish your work faster and with better results. Good control means you’ll make fewer mistakes too!

What Techniques Can Be Employed To Enhance Skill Development When Learning To Use The Handwheel On A Metal Lathe?To get better at using the handwheel on a metal lathe, practice is the key. You can start by turning it slowly to see how it works. It’s also helpful to watch someone experienced and ask them questions. Try setting small goals, like making a straight line, to keep track of your progress. Lastly, don’t forget to take breaks to avoid getting too tired.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Handwheel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a handwheel, always wear safety goggles to protect your eyes. Keep your hair tied back and remove any loose clothing. Make sure your hands are clear of the spinning parts. Always check that tools and the workpiece are securely in place before you start. Lastly, never distract someone while they’re using the lathe.”}},{“@type”: “Question”,”name”: “How Do You Correctly Adjust The Handwheel For Precise Machining On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the handwheel on a metal lathe, first, you check the position of the tool. Turn the handwheel slowly to move the tool closer to the metal. You want to make tiny movements for precise cuts. If the tool is too far or too close, adjust the handwheel a little more. Always double-check your settings before starting the machine.”}},{“@type”: “Question”,”name”: “What Are The Common Issues That Can Arise When Using A Handwheel On A Metal Lathe, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a handwheel on a metal lathe, you might face some problems. One issue is that the handwheel can feel too tight or hard to turn. You can fix this by checking for dirt or oil that needs cleaning. Another problem is if the tool isn’t moving smoothly. You can solve this by making sure everything is lined up correctly and lubricated. Always ask for help if you’re unsure!”}},{“@type”: “Question”,”name”: “How Does The Handwheel Mechanism Affect The Overall Accuracy And Efficiency Of Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The handwheel mechanism helps you control the metal lathe better. When you turn the handwheel, you can move the tool precisely. This makes your cuts more accurate. If you use the handwheel carefully, you will finish your work faster and with better results. Good control means you’ll make fewer mistakes too!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Enhance Skill Development When Learning To Use The Handwheel On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get better at using the handwheel on a metal lathe, practice is the key. You can start by turning it slowly to see how it works. It’s also helpful to watch someone experienced and ask them questions. Try setting small goals, like making a straight line, to keep track of your progress. Lastly, don’t forget to take breaks to avoid getting too tired.”}}]}