Comprehensive Lathe Training Course: Metal Lathe Setup Explained Introduction To Metal Lathe Setup A Metal Lathe Is An Essential Piece Of Machinery In Machining And Manufacturing Processes. Understanding Its Setup Is Crucial For Efficiency And Precision. In This Article, We Will Explore A Lathe Training Course That Focuses Specifically On Metal Lathe Setup, Providing Valuable Insights And Practical Knowledge. Components Of A Metal Lathe Before Diving Into The Setup Process, It’S Essential To Understand The Various Components Of A Metal Lathe: 1. **Bed**: The Base Of The Lathe Where All Other Parts Are Mounted. 2. **Headstock**: Contains The Motor And Provides Drive To The Spindle. 3. **Tailstock**: Supports The Opposite End Of The Workpiece And Can Hold A Drill Bit Or Chuck. 4. **Carriage**: Moves Along The Bed And Houses The Cutting Tool. 5. **Cross Slide**: Allows Lateral Movement Of The Cutting Tool. Benefits Of A Lathe Training Course Engaging In A Lathe Training Course Provides Several Benefits: – **Hands-On Experience**: Learn Practical Skills In Real-World Settings. – **Expert Guidance**: Receive Instruction From Experienced Professionals. – **Safety Practices**: Understand Safety Protocols To Prevent Accidents. – **Skill Enhancement**: Improve Your Machining Capabilities And Techniques. Setting Up A Metal Lathe Setting Up A Metal Lathe Involves Several Critical Steps: 1. **Positioning**: Ensure The Lathe Is On A Stable And Level Surface. 2. **Alignment**: Align The Tailstock And Headstock To Ensure Proper Centering. 3. **Calibrating**: Adjust The Spindle Speed And Feed Rates Based On The Material Type. 4. **Tool Selection**: Choose The Appropriate Cutting Tools For Your Project. 5. **Testing**: Run A Test Piece To Verify The Setup’S Accuracy. Conclusion A Thorough Understanding Of Metal Lathe Setup Is Essential For Anyone Working With Lathe Machinery. Participating In A Lathe Training Course Can Provide Invaluable Skills To Ensure Success In Machining Tasks, Promoting Both Safety And Efficiency In Your Projects. Consider Enrolling In A Course To Enhance Your Capabilities And Confidence In Using A Metal Lathe.

Lathe Training Course Metal Lathe Setup

A lathe training course teaches you how to set up and use a metal lathe effectively. You’ll learn about safety practices, tools, and techniques for precision work. Imagine creating parts that fit perfectly! Understanding the setup of a lathe can help you make amazing projects come to life. Did you know that the right setup can reduce errors and save time? This course helps you master that skill and boost your confidence in metalworking.Importance of Lathe Training

Skills developed through lathe training. Industry demand for trained lathe operators.Lathe training helps people learn important skills. These include precision measuring, tool handling, and machine setup. Each of these skills is key to becoming a great lathe operator. Now, why is this training crucial? Many industries need trained lathe operators. In fact, studies show that skilled workers are in high demand. Employers often have trouble finding qualified people. So, taking a lathe training course can be a smart move. Remember, “A lathe in hand is worth two in the shop!”

| Skill Developed | Industry Demand |

|---|---|

| Precision Measuring | High |

| Tool Handling | Growing |

| Machine Setup | Consistent |

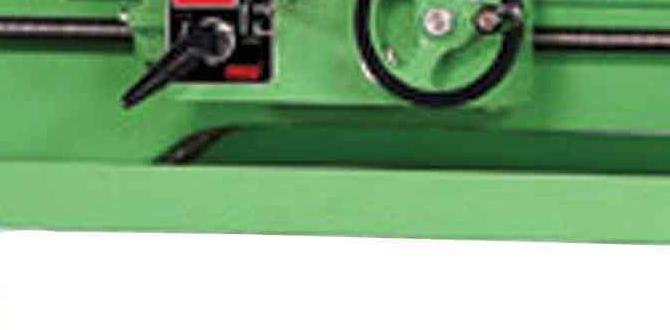

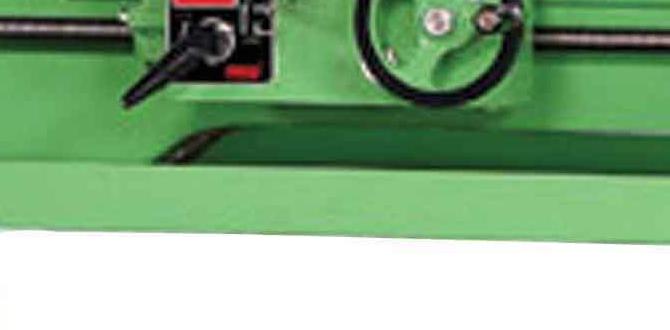

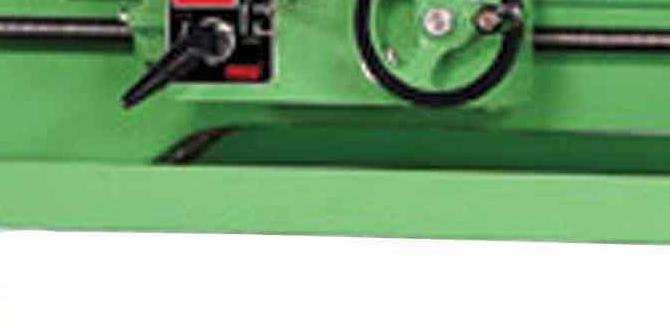

Components of a Metal Lathe

Main parts and their functions. Accessories and attachments for enhanced functionality.A metal lathe has several key parts that work together to shape metal. The main components include the bed, which holds everything steady, and the headstock, where the main motor is. There’s also the tailstock, which helps support the metal. Even the little things matter, like the tool rest, which holds your tools in place. Want more fun? Attach a chuck or a faceplate for extra creativity! These goodies make shaping metal easier and more fun!

| Component | Function |

|---|---|

| Bed | Supports all components |

| Headstock | Houses the motor |

| Tailstock | Provides support |

| Tool Rest | Holds tools safely |

| Chuck | Clamps workpieces |

| Faceplate | Holds irregular shapes |

Choosing the Right Lathe Training Course

Key factors in selecting a course. Comparing online vs. inperson training options.Picking the perfect lathe training course is like choosing the right ice cream flavor – you want to ensure it’s the best for you! First, consider key factors like instructor experience and course content. Then, think about whether you prefer learning online in your pajamas or face-to-face with a mentor, who might have a funny joke or two. Each option has its perks!

| Option | Pros | Cons |

|---|---|---|

| Online | Flexible schedule | No hands-on help |

| In-Person | Direct guidance | Set schedule |

Choose wisely, and you’ll be making metal creations in no time! Remember, a good course is worth its weight in gold – or at least in shiny metal shavings!

Essential Metal Lathe Setup Procedures

Stepbystep guide to setting up a metal lathe. Common mistakes to avoid during setup.Setting up a metal lathe can feel like a puzzle, but fear not! Start with the basics: first, level the lathe on a solid surface. Next, install the chuck and ensure tools are aligned. A well-placed tool rest is key for precision. Watch out for common blunders like skipping the leveling process or using dull tools. They might make your projects spin wildly, and not in a fun way!

| Setup Steps | Common Mistakes |

|---|---|

| 1. Level the lathe | Skipping leveling |

| 2. Install the chuck | Using damaged parts |

| 3. Align tools properly | Using dull tools |

| 4. Adjust tool rest | Neglecting rest height |

Follow these steps to avoid turning your metalwork into a circus show!

Safety Protocols in Lathe Operation

Standard safety practices for lathe operators. Importance of personal protective equipment (PPE).Using a lathe can be fun, but safety must come first. Operators need to follow standard safety practices. Here are key rules:

- Always keep your hands away from the cutting area.

- Secure all materials tightly in place.

- Stay alert and focused during operation.

- Never wear loose clothing or jewelry.

Wearing personal protective equipment, or PPE, is also essential. This includes:

- Safety goggles to protect eyes.

- Ear protection to guard against loud noise.

- Gloves for hand safety.

Following these protocols keeps everyone safe when using a lathe.

What is the importance of personal protective equipment in lathe operation?

Personal protective equipment (PPE) prevents injuries and protects the operator from flying debris.

Resources for Continued Learning

Recommended books and online materials. Networking opportunities in the metalworking community.Learning doesn’t stop after training. Here are some helpful resources. Find books to deepen your skills. Online tutorials can help too. Search for videos that show metal lathe setups in action. Don’t forget about the metalworking community. Networking can open doors. Join local clubs or online forums. This helps you meet experienced workers and share ideas.

- Books: “Metalworking: Tools, Techniques, and Tips”

- Online Courses: Websites like Coursera and Udemy offer great lessons.

- Networking: Attend trade shows or local meetups to connect with others.

What are some good resources for learning about metal lathes?

For metal lathe training, consider reading books and watching online videos. Joining community groups can also help you learn from others’ experiences.

Conclusion

In conclusion, a lathe training course teaches you how to set up a metal lathe properly. You learn essential skills like safety, tools, and techniques. Practical experience boosts your confidence. We encourage you to explore more resources or hands-on workshops to enhance your skills. Let’s get started on your metalworking journey!FAQs

What Are The Essential Safety Precautions To Observe When Setting Up A Metal Lathe For Operation?When setting up a metal lathe, we need to be careful. First, always wear safety glasses to protect your eyes. Make sure the area is clean and free of clutter. Check if all parts are secure and working well. Lastly, never wear loose clothes or jewelry that could get caught in the machine.

How Do You Correctly Align And Adjust The Tailstock And Headstock For Optimal Performance On A Metal Lathe?To align the tailstock and headstock on a metal lathe, first, check if both parts are straight. You can do this by using a ruler or a straight edge. Adjust the tailstock so it’s even with the headstock. You might need to loosen some screws to move it. Finally, make sure everything is tight and secure before you start working. This helps your projects turn out better!

What Types Of Tools And Accessories Are Commonly Used For Setup And Tuning A Metal Lathe?To set up and tune a metal lathe, you need a few tools and accessories. A tool post holds the cutting tools in place. We also use a measuring tool called a caliper to check sizes. A dial gauge helps us see if the lathe is level. Finally, we need wrenches to tighten parts and keep everything secure.

How Can One Determine The Appropriate Spindle Speed And Feed Rate For Different Materials During Lathe Operations?To find the right spindle speed and feed rate, start by knowing your material. Soft materials, like plastic, need a faster speed. Hard materials, like metal, slow down the speed. You can also check guides or charts that show speeds for different materials. Remember, practice helps you get it just right!

What Common Mistakes Should Beginners Avoid When Setting Up And Calibrating A Metal Lathe?When setting up a metal lathe, you should avoid a few common mistakes. First, always make sure the lathe is level. If it’s not level, your work may not be accurate. Second, check that all parts are tight and secure. Loose parts can cause problems while you work. Lastly, remember to measure carefully and double-check your settings before starting.