Have you ever wondered how metal objects are shaped and made? A lathe training course can show you this fascinating process. Learning to use a metal lathe is both fun and rewarding. You get to bring raw materials to life, turning solid metal into beautiful shapes.

Picture this: you start with a dull block of metal. With the right skills, you can create anything from tiny gears to custom tools. An essential part of this process is having a sturdy lathe stand. This stand supports your lathe and keeps it steady, helping you work with ease.

Many people think that using a lathe is only for experts. But anyone can learn with the right training. A lathe training course makes the process simple and enjoyable. It helps you understand the basics and gain confidence. Are you ready to explore the world of metal working?

Essential Lathe Training Course: Mastering Metal Lathe Stand

Exploring Lathe Training Course and Metal Lathe Stand

A lathe training course can unlock the secrets of metalworking. Imagine crafting your own projects with a powerful machine! Participants learn about proper setup, safety techniques, and how to maintain a metal lathe stand. This training not only teaches vital skills but also boosts confidence in using tools. Did you know that learning to operate a lathe can lead to job opportunities in various industries? Dive into this exciting world where creativity meets precision!Understanding Metal Lathe Basics

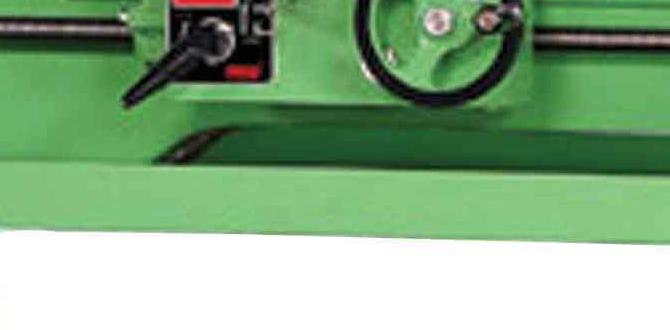

Definition and function of a metal lathe. Key components and their roles in lathe operations.A metal lathe is a special machine that helps shape metal into useful objects. It spins the metal while cutting tools remove material. Think of it as a giant pencil sharpener, but for metal! The main parts of a lathe include the headstock, tailstock, and bed. The headstock houses the motor and spindle, while the tailstock holds tools or workpieces steady. The bed is where everything rests and where magic happens. Together, they transform simple metal blocks into beautiful, precise shapes.

| Component | Function |

|---|---|

| Headstock | Holds and spins the workpiece |

| Tailstock | Supports cutting tools or workpieces |

| Bed | Provides a stable foundation |

Mastering these basics can make you feel like a metal wizard. So, grab your safety goggles and let’s get twisting! Remember, practice makes perfect, but don’t forget—measure twice, cut once!

Importance of Lathe Training Courses

Benefits of structured training for beginners. Career opportunities enhanced by formal training.Structured training is like having a treasure map for beginners. It guides you step by step. With lathe training, you learn to handle machines safely and skillfully. More practice means better results! Did you know that formal training can open many career doors? Skilled lathe operators are in demand. This training lets you shine in fields like manufacturing and crafting. So, get ready to turn some metal and start your dream job!

| Benefit | Description |

|---|---|

| Hands-on Skills | Gain practical experience on actual machines. |

| Job Opportunities | More qualifications mean more job offers! |

What to Expect from a Metal Lathe Training Course

Common curriculum topics covered in courses. Handson experience vs. theoretical learning.In a metal lathe training course, students learn essential skills. Common topics include:

- Lathe operations and safety

- Selecting materials

- Measuring techniques

- Cutting tools and their uses

- Project planning

Students gain hands-on experiences alongside theory. They practice real tasks on machines. This blend makes learning more effective. Many find working on a lathe exciting and rewarding. This approach helps develop confidence and skill.

What is the benefit of hands-on experience in lathe training?

Hands-on experience helps students remember better. They learn by doing, which makes the process fun and engaging.

Types of Lathe Training Courses Available

Online vs. inperson training formats. Certification options and their significance.Various lathe training courses are out there, each offering unique benefits. You can choose between online and in-person formats. Online courses let you learn in your pajamas—bonus points for no awkward classroom moments! On the flip side, in-person training provides hands-on experience. Certification options add a shiny badge to your resume, showing off your skills. Employers often prefer certified candidates; it’s like wearing a superhero cape in the job world!

| Course Format | Benefits |

|---|---|

| Online | Flexible schedule, learn at home |

| In-Person | Hands-on practice, direct guidance |

Choosing the Right Metal Lathe Stand

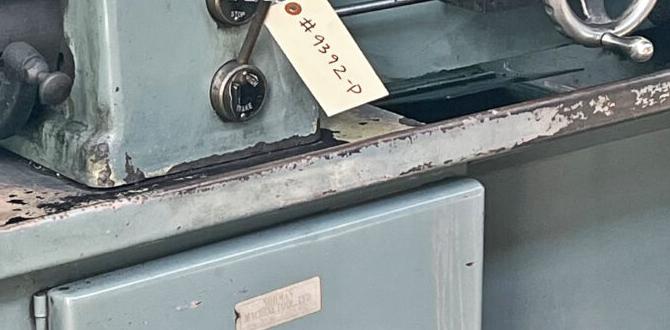

Factors to consider in selecting a lathe stand. Different types of stands: stationary vs. portable.Finding the right metal lathe stand is important. You need something sturdy and designed for your work. Here are some key factors:

- Stability: A good stand keeps your lathe steady and safe.

- Height: Your comfort matters. Choose a height that feels good.

- Storage: Some stands offer extra storage for tools.

There are two main types of stands: Stationary stands stay in one place. They are heavy and stable. Portable stands can be moved easily. They are lighter but may not be as sturdy. Choose what fits your needs best!

What should I consider when buying a lathe stand?

The stand’s stability, height, and storage options are key factors to consider.

Safety Protocols in Lathe Operations

Essential safety gear and equipment. Common safety practices during training.Staying safe while using a lathe is all about wearing the right gear and following rules. Essential safety gear includes goggles to protect your eyes, ear protection to guard against loud noise, and gloves to prevent cuts. During training, it’s crucial to keep hands away from the spinning parts. Always pay attention to the instructor. Here are some important practices:

- Check equipment before use.

- Secure loose clothing and hair.

- Don’t rush; take your time.

What are the key safety rules during lathe training?

Key safety rules include wearing protective gear, keeping tools organized, and following instructions carefully. Always focus on your surroundings to avoid accidents.

Cost of Lathe Training Courses and Equipment

Breakdown of typical course fees and additional costs. Investment in quality stands and their impact on learning.Learning to use a lathe doesn’t have to break the bank, but it does require some smart spending. Course fees typically range from $300 to $1,000, depending on the program. But keep in mind the costs don’t stop there! Investing in a good-quality lathe stand can make a big difference in your learning experience. A sturdy stand helps keep your lathe steady and safe. After all, nobody wants their projects to wobble like a bowl of jelly.

| Item | Estimated Cost |

|---|---|

| Lathe Training Course | $300 – $1,000 |

| Metal Lathe Stand | $100 – $500 |

| Tools and Safety Gear | $50 – $200 |

This investment not only enhances learning but also keeps you safe while you’re getting creative.

Testimonials and Success Stories from Course Graduates

Reallife applications of skills learned. How training has transformed careers.Graduates from the training program often share exciting stories about their new careers. Many found jobs in factories, design shops, and repair centers. The skills they learned helped them stand out. Here are some common themes:

- Increased job confidence

- Higher pay grades

- Opportunities for promotions

One graduate said, “Learning on the metal lathe changed my life.” This training opens many doors. Success stories like these inspire others to join the journey.

What skills do students learn in the course?

Graduates master many useful skills. They learn how to operate a metal lathe, produce precise parts, and improve safety practices. These skills are vital in many industries.

Frequently Asked Questions about Lathe Training

Common queries potential trainees have. Answering concerns regarding course duration and prerequisites.Many people have questions before starting a lathe training course. They often want to know about the length of the course and what skills they need. Here are some common queries:

How long is the lathe training course?

The typical course lasts 4 to 6 weeks, depending on the program. Each session covers essential skills and techniques for using a metal lathe.

What do I need to know before starting?

- No prior experience is required!

- Basic math skills can be helpful.

- It’s good to have a passion for making things!

Conclusion

In conclusion, a lathe training course teaches you how to use a metal lathe effectively. You’ll learn skills for crafting and shaping metal safely. This training boosts your confidence and creativity. We encourage you to explore local courses or online resources. Take the next step to enhance your skills and enjoy working with metal! Happy learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course For Metal Lathe Stand:Sure! Here are some questions about a lathe training course: 1. What is a lathe? A lathe is a machine that spins metal or wood to shape it. 2. What will you learn in the course? You will learn how to use a lathe safely and make cool things. 3. Do you need special clothes? Yes, wear tight clothes and no loose jewelry to stay safe. 4. How long is the course? The course usually lasts a few weeks, with lessons each week. 5. Can you use your own projects? Yes, you can bring your own ideas and make special items.

Sure! Please provide me with the question you’d like me to answer, and I’ll be happy to help.

What Essential Skills And Techniques Will Be Covered In The Metal Lathe Training Course?In the metal lathe training course, you will learn how to safely use a lathe. We will show you how to measure and cut metal pieces. You will practice making cool shapes by turning and sanding. You will also learn how to take care of the machine. By the end, you’ll feel confident using a lathe!

What Safety Protocols Should Participants Be Familiar With Before Operating A Metal Lathe?Before using a metal lathe, you should follow some important safety rules. Always wear safety goggles to protect your eyes. Keep long hair tied back and remove loose clothing to avoid getting caught. Make sure the work area is clean and free of tools or clutter. Lastly, never touch the moving parts while the lathe is on.

How Can A Properly Constructed Lathe Stand Enhance The Functionality And Stability Of A Metal Lathe?A good lathe stand helps your metal lathe work better. It keeps the machine steady, so it doesn’t shake while you use it. This makes it easier to cut metal smoothly. A strong stand also helps you reach all parts of the lathe easily. Overall, it makes your work faster and safer!

What Materials Are Recommended For Building A Sturdy Metal Lathe Stand?To build a sturdy metal lathe stand, you can use steel or heavy plywood. Steel is strong and can hold a lot of weight. Heavy plywood is also good if you want it lighter. Make sure you use thick wood or metal for stability. Don’t forget to add locking casters if you want to move it easily!

Are There Prerequisites Or Prior Experience Required To Enroll In The Metal Lathe Training Course?No, you don’t need any special skills or experience to join the metal lathe training course. You can start as a beginner! The course will teach you everything you need to know. Just come ready to learn and have fun!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course For Metal Lathe Stand:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about a lathe training course: 1. What is a lathe? A lathe is a machine that spins metal or wood to shape it. 2. What will you learn in the course? You will learn how to use a lathe safely and make cool things. 3. Do you need special clothes? Yes, wear tight clothes and no loose jewelry to stay safe. 4. How long is the course? The course usually lasts a few weeks, with lessons each week. 5. Can you use your own projects? Yes, you can bring your own ideas and make special items.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Essential Skills And Techniques Will Be Covered In The Metal Lathe Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In the metal lathe training course, you will learn how to safely use a lathe. We will show you how to measure and cut metal pieces. You will practice making cool shapes by turning and sanding. You will also learn how to take care of the machine. By the end, you’ll feel confident using a lathe!”}},{“@type”: “Question”,”name”: “What Safety Protocols Should Participants Be Familiar With Before Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before using a metal lathe, you should follow some important safety rules. Always wear safety goggles to protect your eyes. Keep long hair tied back and remove loose clothing to avoid getting caught. Make sure the work area is clean and free of tools or clutter. Lastly, never touch the moving parts while the lathe is on.”}},{“@type”: “Question”,”name”: “How Can A Properly Constructed Lathe Stand Enhance The Functionality And Stability Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A good lathe stand helps your metal lathe work better. It keeps the machine steady, so it doesn’t shake while you use it. This makes it easier to cut metal smoothly. A strong stand also helps you reach all parts of the lathe easily. Overall, it makes your work faster and safer!”}},{“@type”: “Question”,”name”: “What Materials Are Recommended For Building A Sturdy Metal Lathe Stand?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a sturdy metal lathe stand, you can use steel or heavy plywood. Steel is strong and can hold a lot of weight. Heavy plywood is also good if you want it lighter. Make sure you use thick wood or metal for stability. Don’t forget to add locking casters if you want to move it easily!”}},{“@type”: “Question”,”name”: “Are There Prerequisites Or Prior Experience Required To Enroll In The Metal Lathe Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “No, you don’t need any special skills or experience to join the metal lathe training course. You can start as a beginner! The course will teach you everything you need to know. Just come ready to learn and have fun!”}}]}