Have you ever wondered how metal objects are made with precision? Imagine creating your own tools or parts with the right skills. A lathe training course can teach you all about this fascinating process, especially when it comes to metal lathe thread cutting.

Thread cutting on a lathe is like making a spiral groove in a piece of metal. This technique is vital in many projects, from machines to everyday items. By learning this skill, you can turn raw metal into something useful.

Many people think this kind of work is too hard. But guess what? With the right training and practice, anyone can become good at it. You don’t need a background in engineering. You just need to be curious and willing to learn.

In this article, we will explore what a lathe training course offers. You will discover important tips and tricks for mastering metal lathe thread cutting. Are you ready to unlock your creative potential? Let’s dive in!

Comprehensive Lathe Training Course: Master Metal Lathe Thread Cutting

Discover Lathe Training Course for Metal Lathe Thread Cutting

Lathe training courses teach essential skills for metal lathe threading. Students learn how to create precise threads for various projects. Hands-on experience helps develop confidence and proficiency. Did you know that thread cutting can improve the strength of your metal pieces? It’s true! This course also covers safety tips to keep everyone safe while working. Getting the right training can open up exciting career opportunities in manufacturing and metalworking. Join today and unleash your potential!Importance of Thread Cutting in Metalworking

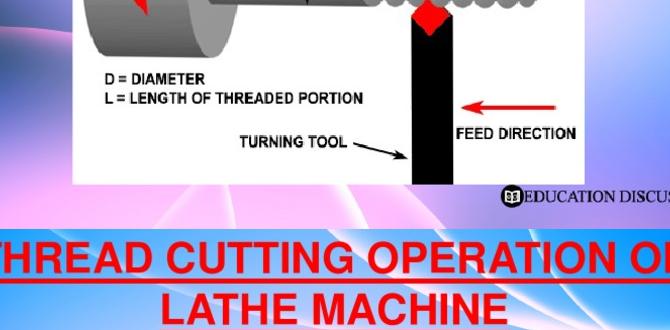

Explanation of thread cutting and its applications in various industries.. Benefits of mastering thread cutting techniques for metalworkers..Thread cutting is the process of creating grooves or paths on metal surfaces. It is important in many industries, like automotive and aerospace. These threads allow parts to fit together and function well.

Mastering thread cutting techniques has big benefits for metalworkers:

- It improves job quality.

- It increases tool life.

- It boosts productivity.

Knowing these skills can lead to more job opportunities and better pay. Thread cutting is key for precise and efficient metalworking.

What is the role of thread cutting in manufacturing?

Thread cutting helps make strong connections between parts. It ensures that bolts and nuts fit perfectly, keeping machines and structures safe.

Course Structure and Learning Outcomes

Detailed breakdown of course topics, including theory and practical sessions.. Expected skills and competencies upon course completion..This course offers a mix of theory and hands-on practice. Students will learn about the metal lathe and its parts. They will also discover the principles of thread cutting. Practical sessions will allow them to apply this knowledge. By the end, students can expect to master:

- Identifying lathe components

- Understanding cutting processes

- Setting up the lathe correctly

- Making precise measurements

- Executing thread cutting accurately

Completing this course makes students confident and skilled metalworkers.

What skills will you gain from the course?

Students will gain skills like machine operation, safety practices, and precision measurement. They will learn to troubleshoot and solve problems during projects. This prepares them for real-world tasks in metalworking.

Essential Tools and Equipment for Thread Cutting

List and description of tools used in thread cutting on a lathe.. Safety equipment and best practices for a secure working environment..To cut threads on a metal lathe, you need specific tools. Here are some important ones:

- Lathe Machine: This is the main tool. It spins the metal while cutting.

- Cuts Tools: These are sharp tools used to shape the thread.

- Thread Pitch Gauge: This helps measure the thread size.

- Caliper: You use this for accurate measurements.

- Tool Holders: They secure cutting tools in place.

Safety is vital. Wear goggles to protect your eyes. Use ear protection if it’s loud. Always keep your workspace clean. Never wear loose clothing that could get caught in the machine.

What safety equipment is needed for thread cutting?

Safety goggles, earplugs, and gloves are essential. They protect you from flying debris and loud noises. A sturdy apron can also keep you safe from sharp tools.

Step-by-Step Guide to Thread Cutting

Detailed instructions on setting up a metal lathe for thread cutting.. Techniques for achieving precise thread dimensions and quality..To set up a metal lathe for thread cutting, start by securing the workpiece in the chuck. Ensure it is tight and aligned. Next, adjust the tool post with a sharp thread-cutting tool. Then, select the right gear for your thread pitch. Use the carriage to control the tool’s movement. Achieving precise threads means testing the depth and feed rate. Take your time, and double-check measurements for quality results.

What is the best technique for thread cutting?

The best technique for thread cutting is to maintain steady speed and pressure. Always keep the tool in contact with the metal. Check your setup before starting to get accurate threads.

Quick Tips for Thread Cutting:

- Always use sharp tools.

- Use cutting oil for smoother cuts.

- Take small passes to avoid mistakes.

Common Challenges and How to Overcome Them

Identification of typical errors made while thread cutting.. Solutions and tips for troubleshooting common issues..Thread cutting can be tricky. Many people make common mistakes, like improper speed and depth settings. This can lead to damaged threads or tools. Here are some tips to help you:

- Start slow and adjust speed as needed.

- Check the tool alignment carefully.

- Use the right cutting fluid to reduce friction.

By following these tips, you can improve your skills and make better cuts. Remember, practice makes perfect!

What are typical errors in thread cutting?

Many errors happen during thread cutting. Typical mistakes include not using the correct pitch and incorrect tool angles. These can lead to poor results.

How to fix common issues in thread cutting?

If you face issues, you can fix them easily. Double-check your settings and keep your tools sharp. These steps will help you make better threads while avoiding mistakes.

Real-World Applications of Thread Cutting Skills

Examples of industries and projects that require thread cutting expertise.. Interview snippets from professionals who utilize these skills in their work..Many industries rely on thread cutting skills. For example, automotive and construction often use these techniques to create strong and precise parts. Professionals say this skill is crucial for safety and efficiency. A mechanical engineer stated, “Thread cutting helps us build cars that last.” Other fields include manufacturing and aviation. In these areas, the ability to cut threads correctly ensures reliable equipment that performs well.

What industries need thread cutting skills?

Industries such as automotive, manufacturing, construction, and aviation require thread cutting skills. These industries use strong, threaded pieces to create safe and reliable products.

Here are some projects that need these skills:

- Building engine components

- Manufacturing tools

- Assembling airplanes

- Creating pipelines in construction

Further Resources for Continued Learning

Recommended books, online courses, and video tutorials for advanced techniques.. Forums and communities for metalworking enthusiasts to share insights..To keep learning about metal lathe thread cutting, explore these resources:

- Books: Check out “Metalworking: Sink or Swim” for hands-on tips.

- Online Courses: Platforms like Udemy and Coursera offer great lessons and videos.

- Video Tutorials: YouTube has many guides from experts showing advanced techniques.

- Forums: Join communities like Reddit’s metalworking group to share and learn from others.

These resources can help deepen your skills and connect with fellow enthusiasts!

What are some good resources to learn more about metal lathes?

Books, online courses, and video tutorials are great for learning. You can also join forums to connect with other metalworking fans.

Conclusion

In summary, a lathe training course on metal lathe thread cutting helps you learn essential skills. You get hands-on experience in making precise threads on metal. This knowledge boosts your confidence and prepares you for real projects. Remember, practice is key! Consider enrolling in a local course or find online resources to explore more. Let’s get started on your metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focused On Metal Lathe Thread Cutting:Sure! Here are five questions about a lathe training course for cutting threads in metal: 1. What do you learn in a lathe training course? In the course, you learn to use a lathe. You learn how to cut threads on metal pieces. 2. Who can take this lathe course? Anyone can take this course! Young people and adults interested in metal working are welcome. 3. Is it dangerous to use a lathe? Yes, it can be dangerous if you don’t follow safety rules. Always wear safety gear and listen to your teacher. 4. How long does the course last? The course usually lasts a few weeks. You meet a few times a week to practice skills. 5. What tools do you use in the course? You use a lathe machine, tools for cutting, and measuring tools. These help you make precise threads on metal.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Are The Essential Safety Precautions To Follow When Operating A Metal Lathe During Thread Cutting?When using a metal lathe for thread cutting, always wear safety goggles to protect your eyes. Keep loose clothing away from the machine to avoid getting caught. Make sure your work area is clean and free of clutter. Always use the right tools and check them before starting. Finally, never try to touch the spinning metal while it’s moving.

How Do You Determine The Correct Thread Pitch And Diameter When Setting Up A Metal Lathe For Thread Cutting?To set up a metal lathe for thread cutting, you need to find out the thread pitch and diameter. First, measure the size of the bolt or nut you want to use. The thread pitch is how far the threads are apart. You can use a thread gauge or count the threads in an inch. Once you have these measurements, you can adjust the lathe to match them.

What Are The Differences Between Cutting Internal And External Threads On A Metal Lathe, And What Specific Techniques Are Required For Each?Cutting internal threads means making grooves inside a hole. You use a special tool that goes into the hole. Cutting external threads creates grooves outside a piece of metal. For this, you move the tool along the metal’s outside surface. You have to set your lathe differently for each type to get the right shape.

Can You Explain The Role Of Tool Geometry And Cutting Speeds In Achieving Accurate Threads While Using A Metal Lathe?Tool geometry is the shape and angle of the cutting tool. It affects how well the tool cuts the metal. If the tool is shaped right, it makes cleaner and more accurate threads. Cutting speed is how fast the tool moves. Faster speeds can make smoother threads, but too fast can ruin them. So, having the right tool shape and speed helps us make good threads on a metal lathe.

What Common Challenges Might Beginners Face When Learning To Cut Threads On A Metal Lathe, And How Can They Be Overcome?Beginners learning to cut threads on a metal lathe might struggle with getting the right measurements. If you measure wrong, the threads can be too loose or too tight. To fix this, always double-check your measurements before starting. Another challenge is keeping the machine steady. Using both hands to hold the tool can help you stay steady and make better cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focused On Metal Lathe Thread Cutting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about a lathe training course for cutting threads in metal: 1. What do you learn in a lathe training course? In the course, you learn to use a lathe. You learn how to cut threads on metal pieces. 2. Who can take this lathe course? Anyone can take this course! Young people and adults interested in metal working are welcome. 3. Is it dangerous to use a lathe? Yes, it can be dangerous if you don’t follow safety rules. Always wear safety gear and listen to your teacher. 4. How long does the course last? The course usually lasts a few weeks. You meet a few times a week to practice skills. 5. What tools do you use in the course? You use a lathe machine, tools for cutting, and measuring tools. These help you make precise threads on metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Essential Safety Precautions To Follow When Operating A Metal Lathe During Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe for thread cutting, always wear safety goggles to protect your eyes. Keep loose clothing away from the machine to avoid getting caught. Make sure your work area is clean and free of clutter. Always use the right tools and check them before starting. Finally, never try to touch the spinning metal while it’s moving.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Thread Pitch And Diameter When Setting Up A Metal Lathe For Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for thread cutting, you need to find out the thread pitch and diameter. First, measure the size of the bolt or nut you want to use. The thread pitch is how far the threads are apart. You can use a thread gauge or count the threads in an inch. Once you have these measurements, you can adjust the lathe to match them.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Cutting Internal And External Threads On A Metal Lathe, And What Specific Techniques Are Required For Each?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cutting internal threads means making grooves inside a hole. You use a special tool that goes into the hole. Cutting external threads creates grooves outside a piece of metal. For this, you move the tool along the metal’s outside surface. You have to set your lathe differently for each type to get the right shape.”}},{“@type”: “Question”,”name”: “Can You Explain The Role Of Tool Geometry And Cutting Speeds In Achieving Accurate Threads While Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool geometry is the shape and angle of the cutting tool. It affects how well the tool cuts the metal. If the tool is shaped right, it makes cleaner and more accurate threads. Cutting speed is how fast the tool moves. Faster speeds can make smoother threads, but too fast can ruin them. So, having the right tool shape and speed helps us make good threads on a metal lathe.”}},{“@type”: “Question”,”name”: “What Common Challenges Might Beginners Face When Learning To Cut Threads On A Metal Lathe, And How Can They Be Overcome?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Beginners learning to cut threads on a metal lathe might struggle with getting the right measurements. If you measure wrong, the threads can be too loose or too tight. To fix this, always double-check your measurements before starting. Another challenge is keeping the machine steady. Using both hands to hold the tool can help you stay steady and make better cuts.”}}]}