Have you ever watched a metal lathe in action? It’s amazing how a simple block of metal can turn into intricate designs. This magic happens thanks to skilled operators and the right training. A lathe training course focuses on both the fundamentals and advanced techniques. It includes key skills like using the threading dial, which helps ensure precise cuts and thread patterns.

Imagine creating your own custom pieces for projects! That’s the power of learning how to use a metal lathe. Many people start as beginners, but with practice, they can become experts. Did you know that mastering the threading dial can significantly speed up your projects? This small tool can make a huge difference in your work.

In this article, we will explore lathe training courses and their benefits. You’ll discover how to improve your skills and build confidence. Whether you’re a hobbyist or planning a career, this information will guide you. Are you ready to unlock the secrets of metal lathe threading? Let’s dive in!

Comprehensive Lathe Training Course: Master Metal Lathe Threading Dial

Lathe Training Course: Mastering Metal Lathe Threading Dial

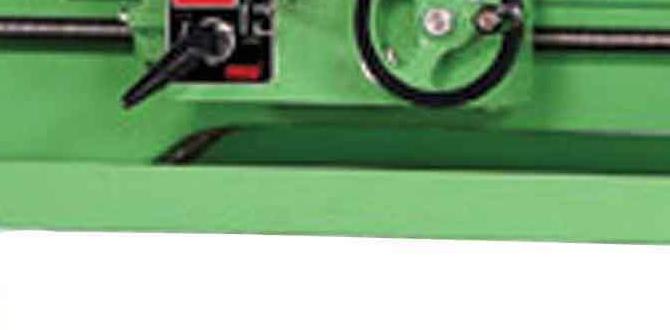

Dive into the world of metal lathes with a comprehensive lathe training course. You’ll learn to operate a metal lathe and master the threading dial, which is essential for precision work. Picture creating perfect threads on your projects. Did you know that even small mistakes in threading can lead to big issues? This course helps you avoid those pitfalls. Gain hands-on skills and confidence to tackle a variety of metalworking tasks. Get ready to make your ideas come alive!The Importance of Threading in Metalworking

Explanation of threading and its applications. Benefits of mastering threading techniques.Threading is a key process in metalworking. It creates grooves into a metal piece, allowing it to hold screws and bolts. This technique is vital for making strong connections in machines and tools. Some benefits of mastering threading include:

- Improved precision in metal parts.

- Increased strength and reliability.

- Ability to create custom solutions.

By mastering threading, you can open doors to exciting projects. It helps you work better and delivers professional results.

Why is threading important in metalworking?

Threading ensures parts fit together securely. It is essential for building safe and effective machines.

Basic Operation of a Metal Lathe

Stepbystep guide on operating a metal lathe. Safety precautions to observe during operation.Using a metal lathe is like working a magic wand to shape metal. Here’s a simple guide to operate it:

- First, secure the workpiece tightly in the chuck.

- Set the lathe speed based on the material type.

- Adjust the threading dial and tool position carefully.

- Switch on the lathe and slowly feed the tool into the workpiece.

- Keep an eye on the workpiece while it turns.

Safety is very important! Always wear goggles and follow these rules:

- Keep your hands away from the spinning parts.

- Don’t wear loose clothing.

- Make sure tools are sharp and in good condition.

With practice, you will create amazing pieces!

What safety gear do I need for lathe operation?

You should wear safety goggles and ear protection. Tight-fitting clothing is also important!

Understanding the Threading Dial

Purpose and mechanics of the threading dial. How to read and adjust the threading dial for accuracy.The threading dial helps you create precise threads on a lathe. It shows how far the tool moves with each turn. To read it, look at the numbers and lines carefully. Always match the dial with your work piece to keep everything in the right place. Adjusting the dial is easy. Turn it until the numbers line up with your desired measurement. Make sure to check it after each pass to ensure accuracy.

How do I read the threading dial?

You can read the threading dial by looking at the numbers on it. Each number shows how far the tool has moved. It’s important to look for straight lines and adjust as needed.

Techniques for Effective Threading

Different threading methods suitable for various applications. Tips for achieving precision and consistency in threading.Threading can be a fun yet tricky activity. There are various methods for different needs. For example, you might use internal threading for nuts and external threading for bolts. Being precise is key! A steady hand and clear measurements help you stay on track. Remember, if you make a mistake, don’t panic. It’s just metal! You can always cut again. Here’s a quick look at some useful threading techniques:

| Method | Best For |

|---|---|

| Single Point | Bolts and shafts |

| Chasing | Duplicating threads |

| Tap and Die | Quick threads |

With practice, threading can become easier. Remember to check your work often. After all, it’s better to fix a thread than to have it spin you around in circles!

Common Challenges in Metal Lathe Threading

Typical problems faced when threading on a lathe. Solutions and troubleshooting techniques for these challenges.Threading on a metal lathe can have its challenges. One common problem is a chatter. This creates a rough surface on the thread. Another issue is incorrect speeds. This can lead to damaged tools. Solutions include adjusting the speed and using the right cutting tools. Inspect your setup often to fix these problems early. Regular practice helps too. Don’t worry, with time, threading becomes easier!

What are typical problems faced during threading?

Common issues include:

- Chatter that causes rough threads.

- Incorrect speed leading to tool damage.

- Improper setup affecting thread depth.

How to troubleshoot these challenges?

Solutions include:

- Adjust the lathe speed.

- Use correct and sharp cutting tools.

- Check the setup regularly for accuracy.

Selecting the Right Lathe Training Course

Factors to consider when choosing a lathe training course. Comparison of online vs. inperson training options.Choosing a lathe training course is exciting but requires thought. Start by looking at your learning style. Do you prefer hands-on learning or virtual classes? Each offers benefits. In-person training helps with direct practice, while online options provide flexibility.

- Experience of the instructor: Check their background.

- Materials covered: Ensure it includes threading dial methods.

- Student reviews: Look for feedback from past students.

Explore different courses before deciding. It’s an important step in your journey.

What are the benefits of online vs. in-person lathe training?

Online training offers flexibility. Students can learn at their pace. In-person classes provide hands-on experience, which is crucial for skills like using a metal lathe threading dial.

Tools and Resources for Enhancing Lathe Skills

Additional tools that can aid in learning lathe techniques. Recommended books, videos, and online communities for support.To improve your lathe skills, several tools can help a lot. Consider adding the following to your workshop:

- Calipers for accurate measurements.

- Indicator gauges to ensure precision.

- Chucks for better workpiece holding.

- Cutting tools specifically for threading.

Supportive resources include:

- Books: Look for titles that explain lathe basics.

- Videos: Find tutorials on YouTube for visual learning.

- Online communities: Join forums to ask questions and share tips.

These tools and resources can make your learning journey fun and effective!

What tools can help when learning lathe techniques?

Essential tools include calipers for precise measurements, indicator gauges for checking accuracy, and cutting tools designed for threading. These help create clean, accurate work. Don’t forget to refer to great online videos for best practices!

Practical Projects to Practice Threading Skills

Examples of projects suitable for beginners. Advanced projects for seasoned learners to tackle threading challenges.Practicing threading skills with projects is fun and rewarding. Beginners can start with simple tasks like making a lamp stand or crafting a small shelf. These projects help you get comfortable with the metal lathe. For seasoned learners, tackling a complex task like a threaded rod or custom bolts presents exciting challenges. Each project builds your skills and confidence!

What are good beginner projects for threading skills?

Simple projects for beginners include:

- Making a lamp stand.

- Creating a small shelf.

- Turning a basic handle.

What advanced projects can help seasoned learners?

Advanced projects include:

- Creating a custom threaded rod.

- Building precision bolts.

- Designing threaded parts for machines.

Conclusion

In summary, a lathe training course teaches you essential skills for using metal lathes, including threading. You’ll learn to produce precise parts and improve your creativity. Hands-on practice will boost your confidence. If you’re interested, look for local classes or online resources to deepen your knowledge. Start your journey into metalworking today and unlock new possibilities!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Threading Dials:Sure! A lathe is a machine that helps us shape metal. In a lathe training course, you learn how to use it safely. We focus on threading dials, which helps make screws and bolts. You get to practice turning the metal and using different tools. It’s really fun and helps you make cool projects!

Sure! Please provide the question you want me to answer.

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?A threading dial on a metal lathe helps you make threads on a piece of metal. When you make threads, you need to move the tool in a very exact way. The threading dial shows you when to stop and change directions. This makes sure the threads fit together perfectly. It helps us create strong and precise threads easily!

What Are The Key Steps To Correctly Set Up And Use A Threading Dial For Cutting Threads On A Metal Lathe?To set up the threading dial on a metal lathe, first, make sure your lathe is turned off. Then, you need to measure the distance from the tool to the workpiece. Next, bring the threading dial to the “0” position. When you’re ready to cut threads, turn the lathe on and move the tool slowly. Watch the threading dial, and when it reaches a number, move the tool forward again to cut more threads. Always be careful and work safely!

How Can A Beginner Troubleshoot Common Issues That Arise When Using A Threading Dial During Threading Operations On A Lathe?To fix problems with the threading dial on a lathe, first, check if the dial is lined up correctly. Make sure it is set to the right number before starting your cut. If the machine makes strange noises, stop and check for loose parts. Sometimes, oiling the parts can help them move better. If you still have issues, ask someone more experienced for help.

What Safety Measures Should Be Observed When Operating A Metal Lathe, Particularly When Using The Threading Dial Feature?When you use a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothing. Make sure your hands stay away from the cutting area. When using the threading dial, turn it slowly and carefully to avoid mistakes. Finally, always double-check your settings before you start.

How Do Different Types Of Threading Dials (E.G., Metric Vs. Imperial) Affect The Threading Process And The Choice Of Tooling In A Metal Lathe Operation?Different types of threading dials help us choose the right size for our threads. Metric dials use millimeters, while imperial dials use inches. If you pick the wrong one, the threads won’t fit together. This means you need special tools for each type. So, knowing which dial to use is really important when working with a metal lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. In a lathe training course, you learn how to use it safely. We focus on threading dials, which helps make screws and bolts. You get to practice turning the metal and using different tools. It’s really fun and helps you make cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial on a metal lathe helps you make threads on a piece of metal. When you make threads, you need to move the tool in a very exact way. The threading dial shows you when to stop and change directions. This makes sure the threads fit together perfectly. It helps us create strong and precise threads easily!”}},{“@type”: “Question”,”name”: “What Are The Key Steps To Correctly Set Up And Use A Threading Dial For Cutting Threads On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the threading dial on a metal lathe, first, make sure your lathe is turned off. Then, you need to measure the distance from the tool to the workpiece. Next, bring the threading dial to the 0 position. When you’re ready to cut threads, turn the lathe on and move the tool slowly. Watch the threading dial, and when it reaches a number, move the tool forward again to cut more threads. Always be careful and work safely!”}},{“@type”: “Question”,”name”: “How Can A Beginner Troubleshoot Common Issues That Arise When Using A Threading Dial During Threading Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with the threading dial on a lathe, first, check if the dial is lined up correctly. Make sure it is set to the right number before starting your cut. If the machine makes strange noises, stop and check for loose parts. Sometimes, oiling the parts can help them move better. If you still have issues, ask someone more experienced for help.”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Observed When Operating A Metal Lathe, Particularly When Using The Threading Dial Feature?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothing. Make sure your hands stay away from the cutting area. When using the threading dial, turn it slowly and carefully to avoid mistakes. Finally, always double-check your settings before you start.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Threading Dials (E.G., Metric Vs. Imperial) Affect The Threading Process And The Choice Of Tooling In A Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of threading dials help us choose the right size for our threads. Metric dials use millimeters, while imperial dials use inches. If you pick the wrong one, the threads won’t fit together. This means you need special tools for each type. So, knowing which dial to use is really important when working with a metal lathe.”}}]}