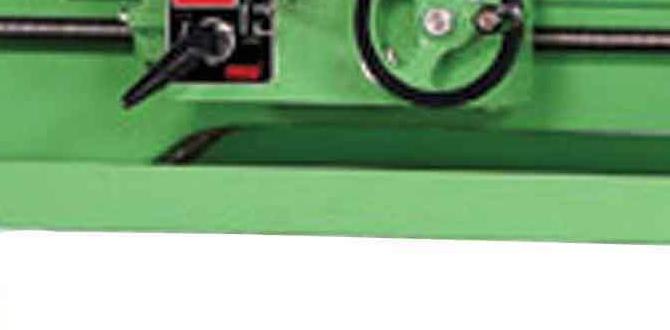

Have you ever seen a metal lathe in action? It’s an impressive machine that shapes metal into many useful items. Picking the right tools and learning how to use them can be an exciting journey. That’s where a lathe training course comes in. If you’re curious about creating your own projects, this course could be the perfect start.

Imagine crafting your own parts and tools. Wouldn’t that be cool? With the right guidance, you can make that dream a reality. In this article, we will explore the amazing world of metal lathe tools. You’ll learn what they are, how they work, and how a lathe training course can help you master them. Get ready to discover what you can create!

Comprehensive Lathe Training Course Using Metal Lathe Tools Lathe Training Courses Are Essential For Anyone Looking To Master The Art Of Working With Metal Lathe Tools. Whether You’Re A Beginner Eager To Learn Or A Seasoned Machinist Looking To Refine Your Skills, A Structured Lathe Training Program Can Make All The Difference. In This Article, We Will Delve Into What These Courses Typically Cover, Their Importance In The Metalworking Industry, And How You Can Choose The Right One For Your Needs. Understanding Lathe Training Courses Lathe Training Courses Are Designed To Equip Participants With The Necessary Skills To Operate Various Types Of Lathes Effectively. These Courses Often Encompass Theoretical Knowledge Along With Hands-On Training, Focusing On The Practical Application Of Metal Lathe Tools. Participants Can Expect To Learn About The Components Of A Lathe, Safety Protocols, And Techniques For Shaping Metal Parts. Importance Of Metal Lathe Tools Metal Lathe Tools Are Indispensable In Machining, Allowing Craftsmen To Turn Raw Metal Into Precise Components. By Mastering These Tools, Students In Lathe Training Courses Can Unlock A World Of Possibilities In Manufacturing And Prototyping. Understanding How To Use These Tools Proficiently Can Lead To Increased Job Opportunities And Better Project Outcomes. Key Components Of A Lathe Training Course 1. **Introduction To Lathe Types**: Students Will Learn About Different Lathe Types, Including Manual And Cnc Lathes, Which Cater To Various Machining Needs. 2. **Safety Protocols**: Safety Is Paramount When Working With Metal Lathe Tools. Training Courses Typically Emphasize Safety Measures To Prevent Accidents And Injuries. 3. **Hands-On Experience**: Practical Training With Metal Lathe Tools Allows Participants To Apply What They Have Learned In A Controlled Environment. 4. **Tool Setup And Maintenance**: Proper Setup And Routine Maintenance Of Lathe Tools Are Critical For Achieving Optimal Performance And Longevity. 5. **Advanced Techniques**: For Those Looking To Enhance Their Skills, Advanced Courses May Cover Complex Machining Techniques And Design Principles. Choosing The Right Lathe Training Course When Selecting A Lathe Training Course, Consider Factors Such As Course Length, Cost, And The Qualifications Of The Instructors. Look For Programs That Offer A Balance Of Theoretical Knowledge And Practical Application. Additionally, Check For Reviews Or Testimonials From Past Participants To Gauge The Course’S Effectiveness. Conclusion Investing In A Lathe Training Course Is A Valuable Step For Anyone Aspiring To Work With Metal Lathe Tools. By Acquiring The Right Skills And Knowledge, You Can Enhance Your Expertise In Machining, Open Up New Career Paths, And Achieve Greater Precision In Your Projects. Whether You’Re A Hobbyist Or A Professional, There’S Always Something New To Learn In The World Of Metalworking.

Lathe Training Course: Mastering Metal Lathe Tools

Want to create amazing metal projects? A lathe training course can help you master metal lathe tools. You’ll learn how to shape and cut metals like a pro. Imagine using a lathe to turn a simple block into a beautiful vase! Courses often cover tool safety, basic techniques, and advanced skills. You’ll also get hands-on practice, making learning fun. By the end, you’ll feel confident and ready to tackle any metalworking challenge. Dive into the world of lathes and unleash your creativity!Benefits of Lathe Training Courses

Enhancing practical skills and technical knowledge. Career advancement and opportunities in machining.Learning to use a lathe is exciting and useful! It builds practical skills that you can use every day. With a lathe training course, you will gain hands-on experience and learn how to work with metal tools safely and effectively. This knowledge can lead to great career opportunities. Many jobs in machining ask for these skills. You can stand out when applying for jobs.

- Improve your hands-on experience.

- Gain technical skills for various jobs.

- Increase your chances of getting hired.

What can you gain from lathe training courses?

In lathe training courses, you can learn new techniques that help you work better and quicker. These skills can open doors to different jobs in the machining industry.

Prerequisites for Enrolling in a Lathe Training Course

Recommended prior knowledge and skills. Age and educational requirements.To join a lathe training course, some basic knowledge helps a lot. It’s good to know metalworking basics and safety rules. Most courses ask for students to be at least 16 years old. A high school diploma or GED is often required. Here’s a quick list of what you need:

- Basic math skills

- Understanding of safety guidelines

- At least 16 years old

- High school education or equivalent

Having these skills can make learning easier and more fun!

What skills are needed before taking a lathe training course?

Prior knowledge in metalworking and safety practices is important. Knowing basic math helps in operating the lathe accurately.

Choosing the Right Lathe Training Course

Factors to consider when selecting a course. Comparison of online vs. inperson training options.Picking the right lathe training course is key. Start by checking if the instructors have experience with metal lathe tools. Look for courses with hands-on training. You can choose between online and in-person classes. Each has its benefits.

- Online courses: Flexible schedule, learn at your own pace.

- In-person courses: Direct interaction, hands-on practice, immediate help.

Consider what suits your learning style best. Your choice can make all the difference in mastering lathe skills.

What questions should I ask before enrolling?

Ask about the course content, duration, and support offered. You want to know if you will receive certificates or job placement help after finishing.

Real-World Applications of Metal Lathe Skills

Industries that require machining and lathe expertise. Examples of projects completed using metal lathe tools.Many industries rely on machining and lathe skills. Think of car makers, aircraft builders, and even toy factories—yep, those shiny toy cars start on a lathe! People use metal lathe tools to create parts like engine components and custom gears.

In fact, over 90% of manufactured items need some lathe work. Here are some fun examples of what you can make:

| Project | Industry |

|---|---|

| Engine Blocks | Automotive |

| Jet Components | Aerospace |

| Custom Tools | Manufacturing |

So, if you’re thinking of taking a lathe training course, remember: those skills can lead to making some seriously cool stuff!

Success Stories from Lathe Training Graduates

Testimonials and career trajectories of former students. Case studies showcasing skill application in the field.Many students celebrate their journey after completing a lathe training course. They often share how the skills learned opened new career doors. For instance, one graduate became a skilled machinist, creating custom parts. Another found joy in teaching others. Here are some success stories:

- John Smith: Now works with top machinery companies.

- Jane Doe: Started her own metalworking business.

- Mark Lee: Teaches lathe skills in high schools.

These students show how lathe training can lead to exciting opportunities and career growth. Their stories are proof that hard work pays off.

What can graduates do with their lathe skills?

Graduates can enter various fields like manufacturing and design. They can also start their own businesses or teach others. Lathe skills offer many career paths.

Conclusion

In conclusion, a lathe training course is essential for mastering metal lathe tools. You learn important skills like precision, safety, and creativity. These tools help you create amazing projects. Now, consider enrolling in a course to sharpen your skills. Explore online resources or local workshops for hands-on practice. Start your journey in metalworking today!FAQs

What Are The Essential Safety Precautions To Follow When Operating A Metal Lathe During The Training Course?When using a metal lathe, wear safety goggles to protect your eyes. Make sure your hair is tied back and no loose clothes are around the machines. Always keep your hands away from moving parts. If something goes wrong, turn off the machine immediately. Remember to ask for help if you’re unsure about anything.

Which Types Of Metal Lathe Tools Are Most Commonly Used, And What Are Their Specific Functions In Machining?The most common metal lathe tools are cutting tools, which help shape metal. We use them to slice, cut, and carve the metal into different shapes. Another tool is the tailstock, which holds bits and helps in drilling holes. Lastly, we have the tool post, which holds the cutting tool steady while we work. Each tool helps us create smooth and准确 (accurate) shapes in metal!

How Does One Properly Set Up And Align A Metal Lathe For Different Machining Tasks During Training?To set up a metal lathe, you first need to make sure it’s on a flat surface. Then, check that the tailstock and headstock line up perfectly. You can do this by using a ruler or a special tool. Next, choose the right tools for your job, like cutting bits. Finally, test the lathe with a small piece of metal to see if it works well. This helps you adjust if needed.

What Are The Key Techniques For Achieving Accurate Measurements And Finishes When Working On A Metal Lathe?To get accurate measurements on a metal lathe, always use a ruler or caliper. Make sure to measure twice before cutting. Keep your tools sharp for smooth finishes. Check your settings regularly to avoid mistakes. Finally, take your time and don’t rush the job.

How Can Beginners Develop Their Skills In Using A Metal Lathe Effectively, And What Practice Projects Are Recommended?To get better at using a metal lathe, you should start with safety first. Always wear safety glasses. Begin with simple practice projects like making a small cylinder or a simple tool holder. These projects will help you learn how to use the lathe. As you grow more comfortable, you can try making parts for toys or small furniture. Keep practicing, and you will improve!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Safety Precautions To Follow When Operating A Metal Lathe During The Training Course? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, wear safety goggles to protect your eyes. Make sure your hair is tied back and no loose clothes are around the machines. Always keep your hands away from moving parts. If something goes wrong, turn off the machine immediately. Remember to ask for help if you’re unsure about anything.”}},{“@type”: “Question”,”name”: “Which Types Of Metal Lathe Tools Are Most Commonly Used, And What Are Their Specific Functions In Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common metal lathe tools are cutting tools, which help shape metal. We use them to slice, cut, and carve the metal into different shapes. Another tool is the tailstock, which holds bits and helps in drilling holes. Lastly, we have the tool post, which holds the cutting tool steady while we work. Each tool helps us create smooth and准确 (accurate) shapes in metal!”}},{“@type”: “Question”,”name”: “How Does One Properly Set Up And Align A Metal Lathe For Different Machining Tasks During Training? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, you first need to make sure it’s on a flat surface. Then, check that the tailstock and headstock line up perfectly. You can do this by using a ruler or a special tool. Next, choose the right tools for your job, like cutting bits. Finally, test the lathe with a small piece of metal to see if it works well. This helps you adjust if needed.”}},{“@type”: “Question”,”name”: “What Are The Key Techniques For Achieving Accurate Measurements And Finishes When Working On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get accurate measurements on a metal lathe, always use a ruler or caliper. Make sure to measure twice before cutting. Keep your tools sharp for smooth finishes. Check your settings regularly to avoid mistakes. Finally, take your time and don’t rush the job.”}},{“@type”: “Question”,”name”: “How Can Beginners Develop Their Skills In Using A Metal Lathe Effectively, And What Practice Projects Are Recommended?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get better at using a metal lathe, you should start with safety first. Always wear safety glasses. Begin with simple practice projects like making a small cylinder or a simple tool holder. These projects will help you learn how to use the lathe. As you grow more comfortable, you can try making parts for toys or small furniture. Keep practicing, and you will improve!”}}]}