Have you ever watched a craftsman turn a block of wood into a beautiful bowl? Or maybe you’ve seen metal get shaped into precise parts? This magic happens on a lathe. But did you know there are different types of lathes? A lathe training course can teach you all about this fascinating equipment. It can help you decide between a metal lathe and a wood lathe.

Think of it like choosing between a paintbrush and a pencil. Each has its special use. But which one is right for you? A metal lathe is great for making strong, durable items. It’s often used in engineering and workshops. On the other hand, a wood lathe brings creativity to life through art. Imagine the things you could create!

Let’s explore both options. Together, we will uncover what makes each lathe unique. What are the skills you need? What can you create? Join us as we delve into the world of lathes!

Lathe Training Course: Metal Lathe Vs Wood Lathe Explained

Lathe Training Course: Metal Lathe vs Wood Lathe

Choosing between a metal lathe and a wood lathe can be exciting. A lathe training course helps you understand both tools. Metal lathes are perfect for making precise parts. They are great for professionals and serious hobbyists. Wood lathes, on the other hand, let you craft beautiful items like bowls and furniture. Did you know that the world’s oldest known lathe dates back over 3,000 years? Learning about these lathes expands your skills and creativity!Types of Lathes

Description of metal lathes. Description of wood lathes.Lathes are tools that help shape materials. There are two main types: metal lathes and wood lathes. Each serves a different purpose.

- Metal lathes: These machines work with metals. They help create parts for machines, cars, and tools.

- Wood lathes: These machines specialize in wood. They are used to make furniture, bowls, and wooden toys.

Both lathes spin the material to carve it into shapes. Understanding these types can help you decide which lathe to learn about.

What is the difference between metal and wood lathes?

Metal lathes handle harder materials, while wood lathes work with softer materials like wood. Each requires different tools and skills.

Key Differences Between Metal Lathes and Wood Lathes

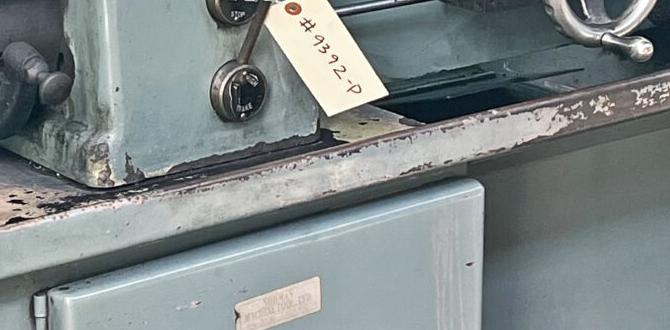

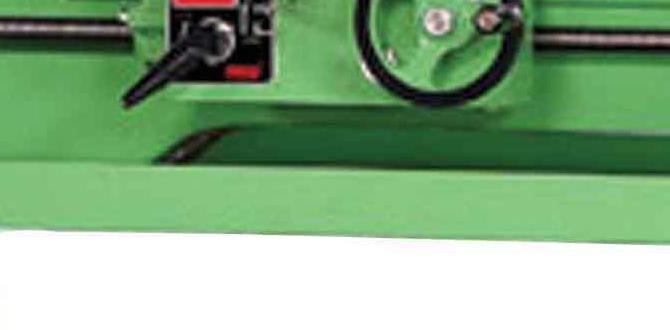

Material compatibility and use cases. Differences in design and operation.Metal lathes are built for toughness; they handle hard materials like steel and aluminum. Think of them like a superhero, fighting the hardest battles. Wood lathes, however, are the gentle giants, perfect for soft woods like pine and cedar. Their designs differ too! Metal lathes have a sturdy structure to withstand heavy work, while wood lathes are more lightweight and easier to move around. It’s like comparing a bulldozer with a cozy pickup truck!

| Aspect | Metal Lathe | Wood Lathe |

|---|---|---|

| Material Compatibility | Steel, Aluminum | Pine, Maple |

| Design | Heavy and sturdy | Light and nimble |

| Use Cases | Machining parts | Creating bowls, spindles |

Applications of Metal Lathes

Common industries using metal lathes. Specific projects suitable for metal lathes.Metal lathes are used in many industries. They help create important parts. Here are some common fields where metal lathes shine:

- Automotive: Making engine parts.

- Aerospace: Creating components for planes.

- Manufacturing: Crafting tools and machinery.

Projects suitable for metal lathes include:

- Making precision shafts.

- Creating custom gears.

- Producing intricate metal rings.

Using metal lathes helps build strong and accurate items. They play a big role in many types of work.

What are common uses of metal lathes?

Common uses include machining metal parts, shaping materials, and creating prototypes.

Applications of Wood Lathes

Typical sectors utilizing wood lathes. Specific projects suitable for wood lathes.Many people use wood lathes in different fields. Furniture makers craft beautiful chairs and tables. Artists often create stunning sculptures. Woodturners make unique bowls and vases. In schools, students learn basic woodcraft skills. These wood lathes help turn plain wood into lovely pieces. Here are some common uses:

- Making decorative items

- Creating wooden toys

- Building custom furniture

- Producing art and sculptures

What projects are best for wood lathes?

Wood lathes work great for bowls, spindles, and unique art pieces. These projects let creativity shine through. Beginners can start with simple shapes, while experts can make complex designs. It’s all about practice and imagination!

Skills Learned in a Lathe Training Course

Essential skills for operating metal lathes. Essential skills for operating wood lathes.In a lathe training course, students pick up some really cool skills! First, they learn to operate metal lathes, mastering techniques like *cutting*, *shaping*, and *finishing* metal pieces. It’s like being a wizard with tools! Next, wood lathe skills include turning and carving wood. Students find out how to create smooth designs and fancy shapes. Who knew making a wooden bowl could be this fun? Check out the essential skills below:

| Skill Type | Metal Lathe Skills | Wood Lathe Skills |

|---|---|---|

| Cutting Techniques | ✔️ | ❌ |

| Turning Wood | ❌ | ✔️ |

| Finishing Techniques | ✔️ | ✔️ |

Choosing the Right Lathe Training Course

Factors to consider when selecting a course. Recommended training programs.Choosing a lathe training course is important for your skills. Start by thinking about what you want to learn. Do you prefer metal, wood, or both? Consider the course length and costs. Check if the course includes hands-on practice. Look at the reviews to see what others say. Here are some recommended programs:

- Community colleges often offer affordable classes.

- Online courses provide flexible learning options.

- Local workshops give hands-on experience.

Finding the right program can help you become a skilled lathe operator!

What factors should I consider when choosing a lathe course?

Key factors include your learning style, budget, and course content.

Are there any specific recommended programs?

- Look into community college offerings.

- Explore online platforms for flexibility.

- Seek out local workshops for practical experience.

Safety Practices in Lathe Operations

General safety precautions for all lathes. Specific safety measures for metal vs wood lathes.Working safely with lathes is very important. Always remember to wear proper gear like goggles and gloves. Here are some general safety tips for all lathes:

- Keep your workspace clean.

- Never reach near the moving part.

- Check tools for damage before use.

- Stay focused; no distractions!

For metal lathes, ensure loose clothing is secured, as it can catch on the machine. For wood lathes, avoid getting sawdust in your eyes by using a face shield. Always be careful while switching between materials.

Why is safety crucial in lathe operations?

Safety helps prevent accidents and injuries. Following rules can save lives. Did you know that 30% of accidents in machine shops happen due to carelessness? Stay safe!

Resources for Further Learning

Books and manuals on lathe operation. Online courses and tutorials available.If you’re curious about mastering lathes, some fantastic resources await! Grab a book or manual on lathe operation—think of it as your trusty sidekick in this journey. Many excellent titles can make complex ideas feel as easy as pie. Online, courses and tutorials abound, too. Just search for “lathe training,” and you might uncover a treasure trove of videos that make learning fun, like a dance-off between a metal and wood lathe!

| Resource Type | Examples |

|---|---|

| Books & Manuals | “Lathe Fundamentals,” “Woodworking with a Lathe” |

| Online Courses | Udemy, Coursera, YouTube Tutorials |

Conclusion

In conclusion, a lathe training course teaches you important skills. Metal lathes create strong, precise parts, while wood lathes focus on artistic pieces. Each type offers unique benefits. If you’re interested in hands-on projects, choose the right lathe for you. Explore courses in your area or online to start your journey. Let’s discover the world of lathes together!FAQs

What Are The Primary Differences In Operation And Design Between Metal Lathes And Wood Lathes?Metal lathes and wood lathes work differently and are built for different materials. A metal lathe is strong and spins metal to shape it. It usually has a heavy base and special tools for cutting hard materials. A wood lathe, on the other hand, is lighter and spins wood to create smooth shapes. It often has simpler tools because wood is easier to cut than metal.

How Do The Specific Tools And Accessories Differ For A Metal Lathe Compared To A Wood Lathe?Metal lathes and wood lathes use different tools because they work with different materials. For a metal lathe, you need sharp metal cutting tools, like chisels and drills. Wood lathes use tools like gouges and scrapers that are better for shaping wood. Also, metal lathes often have more powerful motors since metal is harder to cut than wood. This makes each type of lathe special for its own task.

What Safety Considerations Should Be Taken Into Account When Training On Metal Lathes Versus Wood Lathes?When training on metal lathes, you should wear safety goggles to protect your eyes from flying metal shavings. Always keep your hair tied back and wear tight clothing. For wood lathes, be careful of sharp tools and dust that can get in your eyes or mouth. Always use a dust mask when working with wood. Remember to follow all safety rules and ask for help if you’re unsure of something!

For A Beginner, Which Type Of Lathe Is Recommended For Learning Basic Turning Techniques, And Why?For beginners, a mini lathe is a great choice. It is small and easy to use. You can learn basic turning techniques without feeling overwhelmed. Mini lathes are also less expensive and take up less space. This makes it perfect for starting your turning journey.

How Do The Skill Sets Required For Operating A Metal Lathe Compare To Those Needed For A Wood Lathe?Using a metal lathe and a wood lathe needs some different skills. When you work with metal, you must be careful about how hard the material is. You have to know how to use sharp tools to cut metal. With wood, it’s often easier to shape and sand, so the focus is more on smoothing. Both need practice, but metal lathes can be trickier because of the strength and precision required.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Primary Differences In Operation And Design Between Metal Lathes And Wood Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes and wood lathes work differently and are built for different materials. A metal lathe is strong and spins metal to shape it. It usually has a heavy base and special tools for cutting hard materials. A wood lathe, on the other hand, is lighter and spins wood to create smooth shapes. It often has simpler tools because wood is easier to cut than metal.”}},{“@type”: “Question”,”name”: “How Do The Specific Tools And Accessories Differ For A Metal Lathe Compared To A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes and wood lathes use different tools because they work with different materials. For a metal lathe, you need sharp metal cutting tools, like chisels and drills. Wood lathes use tools like gouges and scrapers that are better for shaping wood. Also, metal lathes often have more powerful motors since metal is harder to cut than wood. This makes each type of lathe special for its own task.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Training On Metal Lathes Versus Wood Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When training on metal lathes, you should wear safety goggles to protect your eyes from flying metal shavings. Always keep your hair tied back and wear tight clothing. For wood lathes, be careful of sharp tools and dust that can get in your eyes or mouth. Always use a dust mask when working with wood. Remember to follow all safety rules and ask for help if you’re unsure of something!”}},{“@type”: “Question”,”name”: “For A Beginner, Which Type Of Lathe Is Recommended For Learning Basic Turning Techniques, And Why? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For beginners, a mini lathe is a great choice. It is small and easy to use. You can learn basic turning techniques without feeling overwhelmed. Mini lathes are also less expensive and take up less space. This makes it perfect for starting your turning journey.”}},{“@type”: “Question”,”name”: “How Do The Skill Sets Required For Operating A Metal Lathe Compare To Those Needed For A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a metal lathe and a wood lathe needs some different skills. When you work with metal, you must be careful about how hard the material is. You have to know how to use sharp tools to cut metal. With wood, it’s often easier to shape and sand, so the focus is more on smoothing. Both need practice, but metal lathes can be trickier because of the strength and precision required.”}}]}