Have you ever wanted to try something new in your woodworking projects? If so, you’re not alone! Many woodworkers look for creative ways to make things just right. One popular tool is the lathe. It can shape wood into beautiful designs. But what happens when you run out of glue blocks?

Don’t worry! There are several clever lathe turning glue block alternative methods. You don’t always need store-bought glue blocks for great results. In fact, many woodworkers have found simple solutions right in their workshops. Imagine using scraps from other projects to create a perfect fit!

Did you know that some people use fruit or vegetable scraps? It’s true! They can make unique and interesting pieces. Exploring these alternatives can lead to stunning outcomes. Who knows what you might create with a little imagination and the right tricks?

So, if you’re eager to learn, stick around. We’ll dive into these alternative methods and show you how easy and fun it can be! Your next project might just surprise you.

Lathe Turning Glue Block Alternative Methods You Should Try

Understanding Glue Blocks in Lathe Turning

Definition and purpose of glue blocks in woodturning.. Common applications and scenarios for using glue blocks..

Glue blocks are helpful tools in woodturning. They hold the piece securely while you shape it. Using glue blocks can save time and make the process easier. You usually use them for:

- Creating unique shapes.

- Fixing broken pieces.

- Mounting wood that’s hard to hold.

They offer stability, which is essential for a smooth finish. With glue blocks, even tricky projects become manageable.

What is the purpose of glue blocks in woodturning?

The purpose of glue blocks in woodturning is to securely attach a piece of wood, allowing for easier shaping and finishing.

Limitations of Traditional Glue Blocks

Discussion of potential issues and drawbacks of glue blocks.. Scenarios where glue blocks may not be suitable..

Glue blocks are useful, but they have some problems. First, they can break easily. This can happen if the wood is weak or not dry. Second, glue blocks may come loose while you’re working. Imagine losing your piece mid-turn! Also, some shapes just don’t fit well with glue blocks.

- They may leave marks on your project.

- Not all woods work with glue.

- Time for drying can be a hassle.

So, while glue blocks are handy, they aren’t always the best choice.

Are there better options than glue blocks?

Yes, there are alternatives! Mounting onto a chuck or using screws can be more reliable. They offer better security and ease during lathe turning.

Using Faceplates for Lathe Turning

Explanation of faceplates as an alternative to glue blocks.. Benefits and drawbacks of using faceplates..

Faceplates are round metal discs that attach to the lathe, holding your wood project securely. Unlike glue blocks, they provide a strong and stable base for turning. One benefit of using faceplates is that they allow easy access to the wood from all sides, giving you freedom to carve and shape it. However, they may add weight and require more set-up time. It’s like having a dance partner who leads, but sometimes steps on your toes!

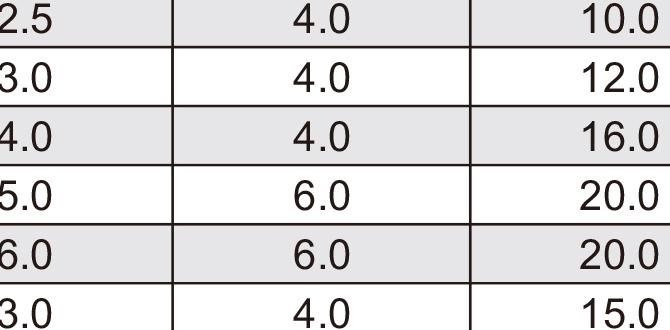

| Benefits | Drawbacks |

|---|---|

| Secure grip on wood | More set-up time |

| Easy access from all sides | Heavier than glue blocks |

Think of faceplates as a reliable friend in your turning journey, but don’t expect them to do the heavy lifting alone!

Exploring Tenon and Mortise Techniques

Description of creating tenons for secure mounting.. Advantages of tenons in various turning projects..

Creating tenons for secure mounting is a fun and crafty way to ensure your work stays put while you spin it on a lathe. Think of tenons like the sturdy legs of a table; they make everything more stable! They are great for projects like furniture or bowls, providing strong joinery. The trick is that tenons can be made in just about any shape, allowing for creative designs without losing stability. Plus, they help reduce the chances of wobbly mishaps—because no one wants a bowl doing the cha-cha on the lathe!

| Advantages of Tenons | Applications |

|---|---|

| Strong Joinery | Furniture Making |

| Versatile Shapes | Bowl Turning |

| Reduces Wobble | Art Projects |

Employing Jigs and Fixtures

Types of jigs and fixtures designed for lathe work.. How to create custom jigs for unique applications..

Jigs and fixtures can make lathe work much easier! These tools hold your materials steady, so you don’t have to. Examples include faceplates and chucks, which are like your trusty sidekicks in woodworking. You can create your custom jigs, too! Just grab some wood and screws to fashion pieces that fit your unique project. Think of it as building a superhero gadget for your lathe. Now, who wouldn’t want that?

| Type of Jig | Purpose |

|---|---|

| Faceplate | Holds large, round pieces |

| Chucks | Grips smaller parts tightly |

| Wooden Jigs | Custom shapes for unique tasks |

Concluding Thoughts on Alternative Methods

Summary of the advantages of exploring alternatives to glue blocks.. Encouragement to experiment with different techniques for optimal results..

Exploring different methods instead of glue blocks can be a smart choice. These alternatives often save time and make projects fun! Sometimes, trying new techniques can lead to better results. So, why stick to the same old ways? Flexibility can lead to creativity. Get your tools ready and give these options a whirl. You might even discover your new favorite method!

| Advantages of Alternatives | Encouragement to Experiment |

|---|---|

| Save time | Try new techniques! |

| Boost creativity | Find your favorite! |

| Improve results | Have fun! |

Conclusion

In summary, exploring lathe turning glue block alternatives can expand your woodworking skills. You can use materials like faceplates, wood screws, or specialized jigs. Each option offers unique benefits. Try different methods to find what works best for you. We encourage you to experiment next time you turn on the lathe and see the difference for yourself! Happy woodworking!

FAQs

What Are The Advantages And Disadvantages Of Using A Glue Block Versus A Tenon When Turning On A Lathe?

Using a glue block has some great benefits. It lets you make shapes that might be hard with a tenon. Glue blocks are also easy to use for some projects. However, they can come apart if not glued well. A tenon fits tightly into the lathe and holds your piece securely. This means it usually doesn’t fall off. But, making a tenon takes more time and practice. If you mess up, you might waste your wood. So, each method has its good and bad sides!

How Can I Securely Mount Irregularly Shaped Blanks Without Using A Traditional Glue Block?

To securely mount irregularly shaped blanks, you can use double-sided tape. This tape sticks to both the blank and your work surface. You can also try using clamps to hold the blank tightly while you work. Another option is to use a faceplate with holes for screws, which can grip the irregular shapes well. Make sure everything is attached firmly so it doesn’t move!

What Are Some Effective Methods For Turning Without A Glue Block For Small Or Delicate Pieces?

You can use a few methods to turn small or delicate pieces without a glue block. First, try using a small scroll chuck, which holds the piece tightly. You can also use a tailstock to support the piece while you work on it. Another way is to use double-sided tape to secure the piece to your work surface. Lastly, you can carefully sand and finish the bottom, and then hold it by hand while turning.

How Can You Use Double-Sided Tape Or Vacuum Chucks As Alternatives To Glue Blocks In Woodturning?

You can use double-sided tape to stick your wood piece to the lathe. Just peel off one side and press it on the wood. Then, peel the other side and attach it to the lathe. Vacuum chucks work by sucking the air out, holding the wood tight without glue. Both ways keep your wood steady while you shape it!

What Are The Best Practices For Removing A Turned Piece From The Lathe When Not Using A Glue Block?

To remove a turned piece from the lathe without a glue block, first turn off the lathe and wait for it to stop. Then, carefully loosen the chuck or the jaws holding your piece. Use a soft cloth to grip the piece if it’s stuck. Gently pull it out while keeping your hands away from the spinning parts. Finally, always check the piece for sharp edges before handling it.