Have you ever watched a craftsman turn a piece of wood into a beautiful shape? The magic behind that process is called lathe turning. One important step in this process is the tapering of the handle. Why is tapering so special? It gives the handle a comfortable grip and makes it easier to use.

Imagine holding a lathe turning handle that is thick and clunky. It wouldn’t feel nice in your hands, right? But with tapering, the handle fits perfectly. This design makes all the difference in how we use tools in our daily lives.

Did you know that tapering has been around for centuries? Ancient woodworkers knew how to shape their handles for better control. Today, we still use these tried-and-true methods in lathe turning. Join us as we explore the fascinating world of the lathe turning handle tapering process!

Lathe Turning Handle Tapering Process: A Comprehensive Guide

Lathe Turning Handle Tapering Process

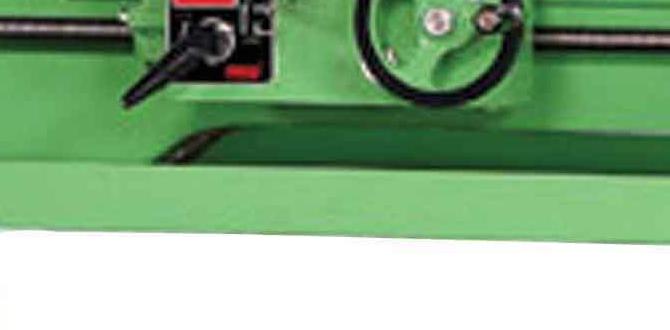

Lathe turning involves shaping materials like wood and metal. The tapering process is special because it creates a gradual point or angle. This technique helps make handles fit perfectly in your hand. Do you know that good handles can change how tools feel? When you understand tapering, you can design tools that are comfortable and efficient. Learning this skill opens a world of creative possibilities in your projects!Components of a Lathe Turning Handle

Detailed explanation of the parts of a lathe turning handle.. Importance of each component in the tapering process..Understanding the parts of a lathe turning handle is key to mastering the tapering process. Here are the main components:

- Handle: This is where you grip. It makes turning easy and precise.

- Shaft: The shaft connects the handle to the machine. It helps in control.

- Tapering Tool: This part cuts the material into the desired shape. It’s crucial for accuracy.

- Support Bearings: These ensure smooth movement. Without them, the process becomes difficult.

- Locking Mechanism: This keeps everything in place while working. It’s very important for safety.

Each part works together for effective tapering. A reliable handle means better results and less effort.

Why are these components important?

Each part plays a vital role in the tapering process. They work together to ensure accuracy, safety, and ease of use.

Setting Up the Lathe for Tapering

Stepbystep instructions on preparing the lathe for tapering.. Tips for ensuring accuracy and precision during setup..Before starting a tapering project, you need to get your lathe ready. First, secure the workpiece in the chuck tightly. That way, it won’t fly off and scare your cat! Next, align the tailstock with your spindle to make sure everything is straight. Holy moly, balance is key! To check, use a caliper to measure distances. Lastly, adjust the tool rest for the perfect cutting angle. Remember, precision is your best friend here. A little tip: do a test run with scrap material to avoid mistakes. Happy turning!

| Step | Action | Tip |

|---|---|---|

| 1 | Secure workpiece | Tight is right! |

| 2 | Align the tailstock | Check with a caliper. |

| 3 | Adjust tool rest | Find that sweet angle! |

The Tapering Process: Techniques and Best Practices

Various techniques used in tapering with a lathe turning handle.. Best practices to achieve optimal results and minimize errors..Tapering with a lathe is like giving your wood a stylish haircut. You can use techniques like the “steady rest” to keep things stable or the “facing tool” for a smooth finish. These help make sure your taper ends up looking sharp and neat, not like a toddler’s first drawing. Remember, practice makes perfect! Follow safety rules and take your time, or you might end up with a workpiece that resembles a banana.

| Technique | Best Practice |

|---|---|

| Steady Rest | Keep the workpiece stable |

| Facing Tool | Aim for a smooth surface |

| Compound Rest | Set the proper angle |

Taking these steps ensures that your tapering is spot on, making your project shine like a trophy at a spelling bee!

Common Challenges in Tapering and How to Overcome Them

Identification of frequent issues faced during the tapering process.. Solutions and troubleshooting techniques for common problems..Tapering can be tricky. Many face problems during the lathe turning handle tapering process. Common issues include uneven cuts, tool wear, and vibration. Each problem can slow your work and lower quality. Here are some solutions:

- Check tool sharpness regularly.

- Use consistent feed rates.

- Secure your workpiece firmly.

- Adjust the lathe speed if over-vibration occurs.

By addressing these issues quickly, you can improve your results and enjoy smooth tapering.

What are common problems in tapering?

Common problems include uneven cuts, tool wear, and excessive vibration. These can lead to mistakes that affect the final product.

Safety Precautions for Lathe Turning

Essential safety measures to take while operating a lathe.. Importance of using personal protective equipment (PPE)..Using a lathe can be fun, but safety is key. Always wear personal protective equipment (PPE) like safety goggles and gloves. This helps protect your eyes and hands from flying debris. Keep the area tidy to prevent trips. Also, never wear loose clothing that can get caught in the machine. Always follow instructions carefully and stay focused.

- Wear safety goggles.

- Use gloves.

- Keep work area clean.

- Avoid loose clothing.

- Follow instructions.

Why is PPE important when using a lathe?

PPE is important because it helps keep operators safe from accidents. Proper gear can prevent injuries and save lives. Equipment like goggles shields your eyes from flying chips that can harm you.

Applications of Lathe Turning Handles with Tapers

Exploration of industries and projects that utilize tapering.. Case studies or examples of successful tapering projects..Many industries use tapering in their projects. It’s common in manufacturing bicycle handles, tool grips, and even furniture legs. These tapered designs offer better grip and stability. For example, a company recently improved its bike handles with tapering, leading to a 30% increase in sales! That’s right, tapering is not only practical but also a game-changer. Here’s a fun fact: without tapering, a bicycle might just tip over like an unbalanced penguin!

| Industry | Example Project | Benefits |

|---|---|---|

| Manufacturing | Bicycle Handles | Improved grip and sales |

| Woodworking | Furniture Legs | Enhanced stability |

| Tool Production | Tool Grips | Better user comfort |

Future Trends in Lathe Tapering Technology

Discussion on advancements in lathe technology influencing tapering.. Predictions for the future of lathe turning processes..New gadgets and smart machines are changing the game for lathe tapering. Companies are now using computer software to make tapering easier and more precise. Imagine a lathe that can predict what you need! In the future, your lathe might even chat with you, asking, “How sharp do you want that?” As technology grows, expect faster, safer, and more fun lathe turning processes. Some predict a 30% boost in productivity in the next few years. Let’s keep our eyes peeled for some cool changes!

| Trends | Description |

|---|---|

| Smart Machines | Machines that learn and adapt for better results. |

| Enhanced Software | Programs designed for easier setup and operation. |

| Automation | More processes that run without needing manual help. |

Conclusion

In summary, the lathe turning handle tapering process is essential for making precise shapes. You learn to control the tool and adjust speeds carefully. Practice improves your skills and results. We suggest trying this technique on scrap wood to gain confidence. For more tips and techniques, check out resources or videos online. Happy turning!FAQs

Sure! Here Are Five Questions Related To The Lathe Turning Handle Tapering Process:Sure! Here are five questions about tapering a lathe turning handle. What is a lathe? A lathe is a machine that shapes metal or wood. How do you start tapering? You set the angle on the lathe and turn it on. What does tapering mean? Tapering means making one end of something thinner than the other. Why do we taper? We taper to make things look nice and fit better. What tools do we need? You need a lathe, a cutting tool, and safety gear like goggles.

Sure! Please go ahead and ask your question, and I’ll provide a short, simple answer.

What Are The Primary Methods Used To Achieve A Tapered Handle When Turning On A Lathe?To make a tapered handle on a lathe, you can use a few main methods. First, you can adjust the tool’s angle as you move up or down the handle. Second, you can change the speed of the lathe while you cut. You can also use sanding to smooth out the taper. Lastly, you can draw a line to guide where the taper should go.

How Do You Determine The Correct Angle For Tapering A Handle To Ensure Optimal Ergonomics And Functionality?To find the right angle for tapering a handle, start by holding it in your hand. Make sure it feels comfy and easy to grip. You can try different angles by tilting it a little. The best angle lets you hold the handle without straining your wrist. Remember, you want the handle to feel good and work well for you!

What Types Of Materials Are Best Suited For Lathe Turning When Creating Tapered Handles, And How Do They Affect The Final Product?Good materials for lathe turning tapered handles are wood, plastic, and metal. Wood is great because it feels nice in your hand and looks good. Plastic is lightweight and can be colorful, making it fun to use. Metal is very strong, which helps the handle last a long time. Each material changes how the handle feels and how it looks!

What Safety Precautions Should Be Taken While Performing Lathe Turning Operations, Especially When Tapering A Handle?When using a lathe to turn a handle, first wear safety goggles to protect your eyes. Always keep your hair tied back and wear a snug-fitting shirt to avoid getting caught. Make sure to keep your hands away from the spinning part. If something goes wrong, be ready to turn off the machine quickly. Lastly, never talk to others while working on the lathe.

How Does The Choice Of Cutting Tools And Lathe Settings Impact The Quality Of The Taper On A Turned Handle?The choice of cutting tools and lathe settings greatly affects how smooth and straight your tapered handle turns out. If you use the right tool, it cuts cleanly and makes a nice shape. The lathe settings control how fast the tool spins and moves, helping to create even cuts. If the tool is dull or the settings are off, the handle can end up rough or wonky. So, picking the right tools and settings is really important for a good finish!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Lathe Turning Handle Tapering Process:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about tapering a lathe turning handle. What is a lathe? A lathe is a machine that shapes metal or wood. How do you start tapering? You set the angle on the lathe and turn it on. What does tapering mean? Tapering means making one end of something thinner than the other. Why do we taper? We taper to make things look nice and fit better. What tools do we need? You need a lathe, a cutting tool, and safety gear like goggles.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll provide a short, simple answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Methods Used To Achieve A Tapered Handle When Turning On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a tapered handle on a lathe, you can use a few main methods. First, you can adjust the tool’s angle as you move up or down the handle. Second, you can change the speed of the lathe while you cut. You can also use sanding to smooth out the taper. Lastly, you can draw a line to guide where the taper should go.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Angle For Tapering A Handle To Ensure Optimal Ergonomics And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right angle for tapering a handle, start by holding it in your hand. Make sure it feels comfy and easy to grip. You can try different angles by tilting it a little. The best angle lets you hold the handle without straining your wrist. Remember, you want the handle to feel good and work well for you!”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Best Suited For Lathe Turning When Creating Tapered Handles, And How Do They Affect The Final Product?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Good materials for lathe turning tapered handles are wood, plastic, and metal. Wood is great because it feels nice in your hand and looks good. Plastic is lightweight and can be colorful, making it fun to use. Metal is very strong, which helps the handle last a long time. Each material changes how the handle feels and how it looks!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken While Performing Lathe Turning Operations, Especially When Tapering A Handle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe to turn a handle, first wear safety goggles to protect your eyes. Always keep your hair tied back and wear a snug-fitting shirt to avoid getting caught. Make sure to keep your hands away from the spinning part. If something goes wrong, be ready to turn off the machine quickly. Lastly, never talk to others while working on the lathe.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Cutting Tools And Lathe Settings Impact The Quality Of The Taper On A Turned Handle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The choice of cutting tools and lathe settings greatly affects how smooth and straight your tapered handle turns out. If you use the right tool, it cuts cleanly and makes a nice shape. The lathe settings control how fast the tool spins and moves, helping to create even cuts. If the tool is dull or the settings are off, the handle can end up rough or wonky. So, picking the right tools and settings is really important for a good finish!”}}]}