Have you ever wondered how those cool key chain fobs are made? The lathe turning process is a fascinating craft that brings these tiny treasures to life. Imagine a piece of wood or metal spinning quickly while a sharp tool shapes it into a perfect fob. It’s like magic!

In the world of DIY projects, lathe turning is an exciting skill to learn. With just a few tools and some practice, anyone can create their unique key chain fob. Plus, it’s a fun way to make gifts for friends and family. Who wouldn’t love a special item made just for them?

Did you know that many people use lathe turning as a relaxing hobby? They find joy in watching raw materials transform into beautiful pieces. The sense of accomplishment is incredible. So, let’s dive into the lathe turning key chain fob process and explore how you can start making your special creations today!

Lathe Turning Key Chain Fob Process: A Complete Guide

Understanding Lathe Turning

Definition and purpose of lathe turning. Key components of a lathe machine.

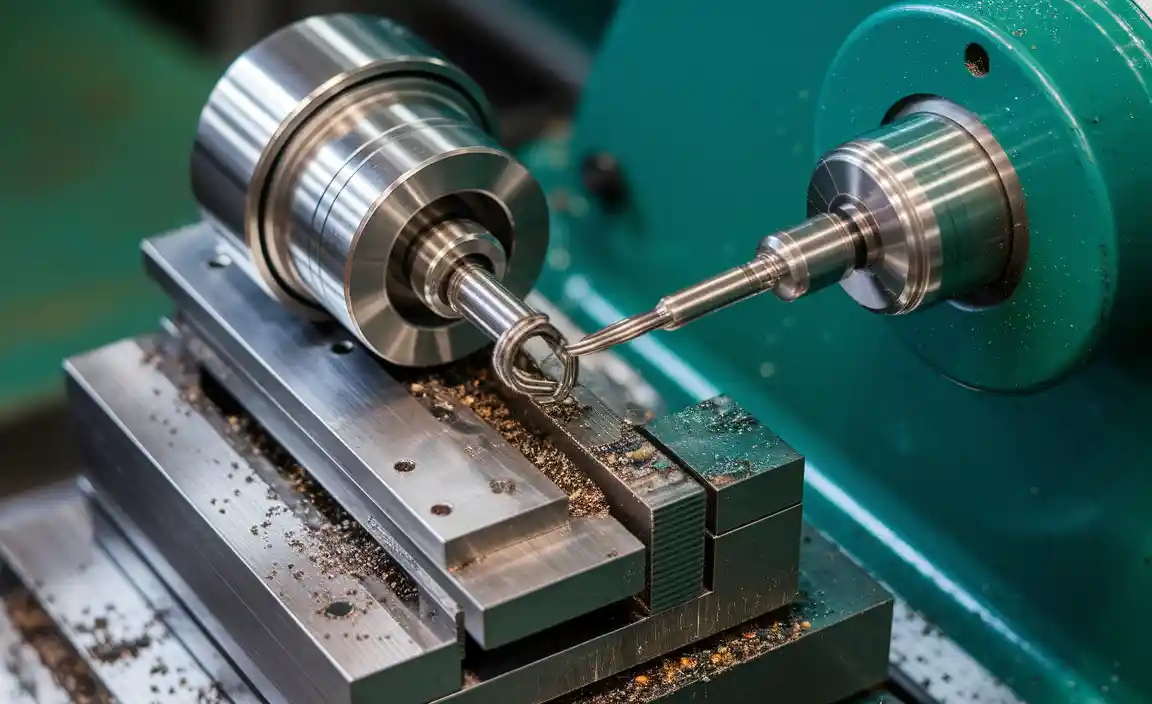

Lathe turning is a process that shapes materials like wood and metal. A lathe spins the material while cutting tools carve it into the desired shape. This technique is used to create items like key chains or table legs. The main parts of a lathe include:

- Headstock: Holds the motor and spins the workpiece.

- Tailstock: Supports the other end of the workpiece.

- Carriage: Moves the cutting tool across the spinning material.

- Bed: Provides a stable base for the machine.

This exciting process allows people to make unique and useful items easily!

What is the purpose of lathe turning?

The purpose is to shape materials into specific designs, making tools, parts, and decorative items.

Materials Needed for Key Chain Fob Making

Types of wood and metal suitable for fobs. Essential tools and supplies for the process.

To make a fun key chain fob, you need some cool materials. First, consider using woods like maple or walnut. They look great and smell awesome! If metal is more your style, try aluminum or brass. They add a shiny touch. Now, for the tools, grab a lathe, some saws, and sandpaper. Don’t forget safety glasses! You don’t want wood chips flying into your eye. Below is a handy table for quick reference:

| Material Type | Examples |

|---|---|

| Wood | Maple, Walnut, Cherry |

| Metal | Aluminum, Brass, Stainless Steel |

Now, get crafty and let your imagination soar! Happy fobbing!

Safety Precautions When Using a Lathe

Personal protective equipment requirements. Common hazards and how to avoid them.

Working with a lathe can be fun, but safety is key! Always wear personal protective equipment like goggles and gloves to keep yourself safe. Watch out for common hazards like flying objects and sharp tools. Keep your workspace tidy to avoid tripping. Remember, a clean shop is a happy shop! If you hear strange noises, it’s time to investigate, not time to do the angry dance. Stay alert, and you’ll turn that key chain fob like a pro!

| Safety Gear | Common Hazards | Precautions |

|---|---|---|

| Goggles | Flying debris | Keep the area clear |

| Gloves | Sharp tools | Handle with care |

| Ear protection | Noisy equipment | Stay focused |

Step-by-Step Process of Turning a Key Chain Fob

Preparing the material and equipment setup. Detailed turning techniques and tips for success.

Preparing for lathe turning starts with choosing the right material. Common choices include wood, plastic, or aluminum. Gather your tools: a lathe, cutting tools, and safety gear. Set everything up for a smooth process. Use these turning tips to handle the tool with care:

- Start slowly to get used to the lathe.

- Maintain even pressure while cutting.

- Always measure twice for accuracy.

Practice makes perfect, so keep going until you feel confident!

What materials do I need for lathe turning?

You need wood, plastic, or aluminum, plus a good lathe and cutting tools.

Design Considerations for Custom Key Chain Fobs

Popular styles and shapes for fobs. Incorporating personalization and unique features.

Custom key chain fobs can be fun and stylish. Popular styles include shapes like hearts, animals, and logos. These designs make fobs look cool and unique. Personalization is key! Add names, initials, or special dates to make each fob special. Unique features like colors or charms can also stand out. Here are some ideas for styles:

- Animals: Cats, dogs, and birds.

- Shapes: Stars, hearts, or geometric forms.

- Themes: Sports, hobbies, or favorite shows.

These choices help you create a fob that shows off your personality.

What styles are best for key chain fobs?

Animals, hearts, and favorite themes work great for key chain fobs. These styles make your fob fun and personal.

Finishing Techniques for a Professional Look

Sanding and polishing methods. Applying finishes and protective coatings.

To achieve a professional look for your lathe turning key chain fob, it’s important to focus on finishing techniques. Start with sanding. Use smooth grit sandpaper to eliminate rough spots. This will create a nice surface. After sanding, polishing is next. Use a soft cloth for a shiny finish.

Apply protective coatings, too. They keep your fob safe from scratches and water. A clear coat works well. Be sure to follow the manufacturer’s instructions for the best results.

- Sanding removes imperfections.

- Polishing gives a shiny look.

- Coatings protect your work.

What is the best way to finish a lathe-turned project?

The best way to finish a lathe-turned project is to sand, polish, and apply protective coatings. These steps will enhance the appearance and durability of your key chain fob.

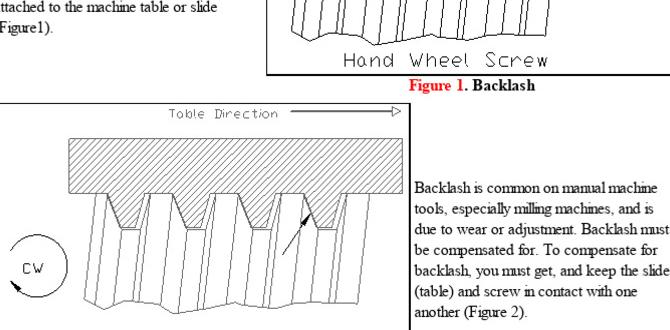

Common Mistakes to Avoid During the Turning Process

Identifying frequent errors in technique. Solutions and adjustments to improve results.

Many new turners make common mistakes during the lathe turning process. These errors can affect the quality of your key chain fob. For example, using the wrong speed can cause uneven cuts. Also, not supporting the piece well can lead to breakage. Here are some mistakes to avoid:

- Not checking tool sharpness

- Failing to secure the workpiece

- Ignoring feed rate adjustments

To fix these issues, always check your tools before starting. Make sure your workpiece is tight and secure. Finally, adjust your speed and feed to match the material. These solutions will improve your results!

What are the top mistakes in lathe turning?

The top mistakes in lathe turning include using dull tools, incorrect speeds, and poor workpiece support. These lead to bad results and can affect safety.

Showcasing Your Work: Ideas for Marketing Key Chain Fobs

Strategies for presenting and selling your fobs. Utilizing online platforms and social media for visibility.

To share your key chain fobs, think about smart ways to show them off! You can use social media like Instagram and Facebook. These platforms help you reach many people. It’s fun to post pictures and videos of your fobs. Consider these ideas:

- Join craft fairs or local markets to meet buyers.

- Create a website to sell your fobs online.

- Collaborate with local shops to feature your designs.

Your creativity deserves a spotlight. Let others see your amazing work!

How can I promote my key chain fobs online?

Promote your key chain fobs by using social media. Share engaging posts like photos and stories. Create ads to spread the word. Always respond to comments and questions to build a loyal following.

Conclusion

In summary, the lathe turning key chain fob process is fun and creative. You learn to shape materials like wood or metal. This project develops your skills and makes great gifts. Try it yourself to create unique designs. Explore more about lathe tools and safety tips to get started. You’ll enjoy making something special!

FAQs

What Materials Are Commonly Used For Creating A Lathe-Turned Key Chain Fob, And How Do Their Properties Influence The Final Product?

You can make a lathe-turned key chain fob from wood, metal, or plastic. Wood looks nice and feels warm. Metal is strong and shiny, while plastic is lightweight and colorful. Each material changes how the fob feels and looks in your hand. This helps you choose a fob that you really like!

What Are The Essential Tools And Equipment Needed To Set Up A Lathe For Turning A Key Chain Fob?

To set up a lathe for turning a key chain fob, you need a few important tools. First, you need the lathe itself, which spins the material. Next, grab some cutting tools to shape the fob. You’ll also need a ruler or caliper to measure carefully. Finally, have safety glasses to protect your eyes while you work.

What Are The Step-By-Step Instructions For Shaping And Finishing A Key Chain Fob On A Lathe?

To shape and finish a key chain fob on a lathe, you first need to gather your materials. Start by placing your wood piece on the lathe. Turn the lathe on and carefully shape the wood with a sharp tool, making it smooth. You can change the shape by moving the tool around. Finally, use sandpaper to smooth out the surface, then apply a finish like oil or varnish to make it shine.

How Can Different Lathe Turning Techniques, Such As Cutting And Sanding, Affect The Design And Durability Of A Key Chain Fob?

Different lathe turning techniques can change how your key chain fob looks and how strong it is. When you cut the wood, it creates sharp shapes and clean edges. This can make your design look cool and unique. Sanding makes the fob smooth and comfortable to hold, but it can also make it thinner and less strong. So, the way you turn the lathe affects both the fun design and how long your fob will last!

What Safety Precautions Should Be Taken When Operating A Lathe While Crafting A Key Chain Fob?

When using a lathe to make a key chain fob, you should wear safety goggles to protect your eyes. Make sure your hair is tied back and your clothes are snug so nothing gets caught. Keep your hands away from the spinning parts. Always turn off the lathe before you change your project or tools. Lastly, stay focused and don’t talk to others while you’re working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Creating A Lathe-Turned Key Chain Fob, And How Do Their Properties Influence The Final Product? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make a lathe-turned key chain fob from wood, metal, or plastic. Wood looks nice and feels warm. Metal is strong and shiny, while plastic is lightweight and colorful. Each material changes how the fob feels and looks in your hand. This helps you choose a fob that you really like!”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Needed To Set Up A Lathe For Turning A Key Chain Fob? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a lathe for turning a key chain fob, you need a few important tools. First, you need the lathe itself, which spins the material. Next, grab some cutting tools to shape the fob. You’ll also need a ruler or caliper to measure carefully. Finally, have safety glasses to protect your eyes while you work.”}},{“@type”: “Question”,”name”: “What Are The Step-By-Step Instructions For Shaping And Finishing A Key Chain Fob On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To shape and finish a key chain fob on a lathe, you first need to gather your materials. Start by placing your wood piece on the lathe. Turn the lathe on and carefully shape the wood with a sharp tool, making it smooth. You can change the shape by moving the tool around. Finally, use sandpaper to smooth out the surface, then apply a finish like oil or varnish to make it shine.”}},{“@type”: “Question”,”name”: “How Can Different Lathe Turning Techniques, Such As Cutting And Sanding, Affect The Design And Durability Of A Key Chain Fob? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe turning techniques can change how your key chain fob looks and how strong it is. When you cut the wood, it creates sharp shapes and clean edges. This can make your design look cool and unique. Sanding makes the fob smooth and comfortable to hold, but it can also make it thinner and less strong. So, the way you turn the lathe affects both the fun design and how long your fob will last!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Lathe While Crafting A Key Chain Fob? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe to make a key chain fob, you should wear safety goggles to protect your eyes. Make sure your hair is tied back and your clothes are snug so nothing gets caught. Keep your hands away from the spinning parts. Always turn off the lathe before you change your project or tools. Lastly, stay focused and don’t talk to others while you’re working.”}}]}