Have you ever wondered how longboard rollers are made? It’s a fascinating process that involves lathe turning. Many people may not realize what goes into creating the smooth wheels that make longboarding fun.

Imagine cruising down a hill, the wind in your hair. The wheels beneath you gliding effortlessly. That’s the magic of well-crafted longboard rollers. But how are these essential parts created?

Lathe turning is the art of shaping wood or metal into perfect circles. This skill is vital in creating longboard rollers. The precision required ensures the wheels roll smoothly and don’t wobble.

A fun fact: Did you know that the oldest known lathe dates back to ancient Egypt? Craftsmen have used this tool for thousands of years. Today, it’s still going strong in making modern longboard rollers.

By exploring the world of lathe turning, we can better appreciate the craftsmanship behind our favorite ride. Let’s dive into this amazing process together!

Lathe Turning Longboard Rollers: Crafting Precision Wheels

Understanding Lathe Turning

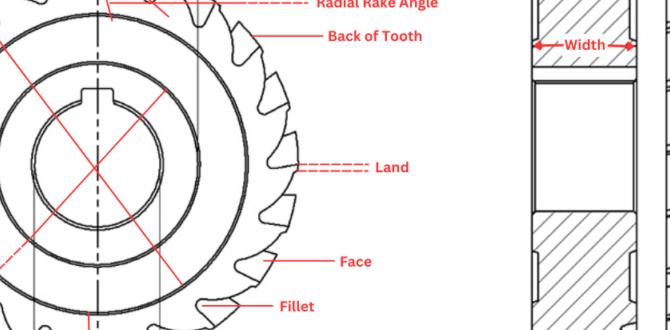

Definition and importance of lathe turning in manufacturing.. Types of lathes used for turning projects..

Lathe turning shapes materials into desired forms. It’s crucial in making parts for many products. This process is important for accuracy and smooth finishes. It helps create items like longboard rollers effectively. Different types of lathes serve specific needs. Here are some common types:

- Engine Lathe: Used for general purposes.

- CNC Lathe: Automated for precision work.

- Turret Lathe: Great for mass production.

Each lathe type offers unique benefits, enhancing the manufacturing process.

Why is lathe turning important in manufacturing?

Lathe turning is vital for creating precise shapes and smooth surfaces in manufacturing. It makes parts that fit well and work correctly, ensuring quality products.

Materials Used for Longboard Rollers

Common materials suitable for longboard rollers and their properties.. Pros and cons of different materials (wood, plastic, metal)..

Choosing the right material for longboard rollers affects performance and comfort. Here are some common materials:

- Wood: It’s natural and provides a smooth ride. However, it can splinter and wear out faster.

- Plastic: This is lightweight and affordable. It may crack under heavy use, though.

- Metal: Metal is strong and durable. But it can be heavy, making the board harder to control.

Each material has its own benefits and drawbacks, so pick what suits your style best.

What are the best materials for longboard rollers?

Wood, plastic, and metal are popular choices for longboard rollers. Each has unique properties. For fun rides, wood offers flexibility. Plastic is great for quick turns, while metal ensures longevity. Choose what feels right for your skating experience!

Designing Longboard Rollers

Key design considerations for optimal performance.. How to create design specifications and dimensions..

Creating great longboard rollers means thinking about a few key design points. First, roller size is vital—too small, and your ride feels bumpy; too big, and you’ll be rolling straight into trouble! Next, material choice matters, as it impacts grip and durability. Choosing the right width can balance stability and speed, giving you a wild ride without risking a tumble. But don’t get stuck in numbers—design is also about fun!

| Design Factor | Consideration |

|---|---|

| Size | Effect on ride quality |

| Material | Grip & durability |

| Width | Stability vs. speed |

Once you’ve got your ideas, create specific designs and dimensions. Measure twice, cut once! It’s all about balance, style, and keeping it fun. So grab your tools, and get ready for a ride like no other!

Setting Up the Lathe for Turning Rollers

Stepbystep setup process for lathes.. Safety measures and essential tools needed..

Getting your lathe ready is like prepping for a big cooking show—everything needs to be just right! First, you’ll need to make sure your lathe is clean and well-oiled to avoid any sticky situations. Check the power supply and level it on a sturdy workbench. You don’t want it wobbling around like a jelly on a skateboard!

Next, gather your essential tools, like chisels and calipers. A solid pair of safety glasses is a must, unless you enjoy having wood splinters in your eyes. Remember the steps: secure the workpiece, adjust the speed, and keep your hands far away from the spinning monster! Always keep a fire extinguisher nearby—just in case your work gets a little too ‘hot’!

| Essential Tools | Safety Measures |

|---|---|

| Chisels | Wear Safety Glasses |

| Calipers | Keep Hair Tied Back |

| Sandpaper | Use a Fire Extinguisher |

By following these steps, you’ll be well on your way to creating the best longboard rollers in town! Remember, a well-set lathe is happy, and a happy lathe means fewer surprises.

Turning Techniques for Longboard Rollers

Techniques for smooth and precise turning.. Tips for achieving the desired finish on rollers..

For smooth and precise turning, keep your lathe tools sharp. Dull tools can be like trying to cut a steak with a butter knife—frustrating! Start with a slow speed. This lets you better control your cuts. Using the right angle is key too. Think of it like steering a bike: lean just right for a smooth turn.

When aiming for that perfect finish on your longboard rollers, sandpaper is your best friend. Use finer grits as you get closer to the final shape. This ensures a silky-smooth surface. Also, consider using a finish like varnish, which is like sunscreen for wood—it protects and shines!

| Technique | Tip |

|---|---|

| Sharp Tools | Keep them honed! |

| Slow Speeds | More control, more fun! |

| Sanding | Start rough, finish smooth! |

With these tips, you’ll be on your way to creating longboard rollers that glide like butter on toast. So, ready, set, turn!

Post-Turning Processes

Necessary finishing techniques after lathe turning.. Importance of inspection and quality control..

After lathe turning, it’s important to make the rollers smooth and strong. Finishing techniques like sanding help remove any rough spots. This step makes the surface even better for sliding. Then, inspection starts. Checking for any mistakes is key. Quality control ensures the rollers work well and last a long time.

- Use sandpaper for smoothing.

- Check for any cracks or dents.

- Make sure sizes match the design.

Why is inspection important?

Inspection helps catch problems early. Finding issues ensures the rollers are safe and effective.

Common Issues and Solutions in Lathe Turning

Troubleshooting typical problems encountered during the turning process.. How to avoid common mistakes..

Lathe turning can be tricky. You might face unexpected issues during the process. Understanding these common problems helps avoid mistakes. Here are some typical concerns and solutions:

- Vibration: This can happen if the lathe isn’t stable. Ensure it is on a flat surface.

- Tool wear: Dull tools can ruin your work. Check tool sharpness regularly.

- Dimensional errors: This may occur from incorrect measurements. Always double-check your sizes before starting.

- Surface finish: A rough finish can be fixed by adjusting speeds. Play with speeds to find what works best.

By knowing these problems, you can turn your longboard rollers with ease and success!

What are common problems in lathe turning?

Common problems in lathe turning include vibration, tool wear, dimensional errors, and poor surface finish. Identifying these issues early helps in making corrections quickly.

Conclusion

In conclusion, lathe turning longboard rollers can enhance your riding experience. You can create smooth, durable rollers for better stability. It’s fun and rewarding to customize your gear. Consider trying this process yourself or reading more about it online. With practice, you’ll improve your skills and enjoy a smoother ride. So, grab your tools and get started today!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Longboard Rollers:

Sure! Here are some answers about turning longboard rollers on a lathe: 1. **What is a lathe?** A lathe is a machine. It spins wood or metal to shape it. 2. **Why do we turn longboard rollers?** We turn longboard rollers to make them smooth and round. This helps the longboard roll better. 3. **What materials can we use?** You can use wood or plastic for longboard rollers. Both work well. 4. **How do you make sure they are even?** We measure carefully and watch while the lathe spins. This helps us make them just right. 5. **What tools do you need?** You need a lathe, some cutting tools, and safety gear. Safety gear keeps you safe while you work.

Sure! Please provide the question you would like me to answer.

What Types Of Materials Are Commonly Used For Lathe Turning Longboard Rollers And What Are Their Advantages?

Common materials for making longboard rollers include plastic, rubber, and hard woods. Plastic is lightweight and can be colorful. Rubber gives good grip and makes rides smoother. Hard woods are strong and look nice. Each material has its own benefits for riding comfort and durability.

How Do You Determine The Appropriate Dimensions And Specifications For Longboard Rollers During The Lathe Turning Process?

To find the right sizes for longboard rollers, you start by knowing what the longboard needs. You can measure other rollers or check guidelines for their sizes. Next, you decide how thick and wide you want them to be. Then, when using the lathe, you carefully adjust the settings to make sure they are shaped correctly. Always double-check your measurements as you work!

What Are The Essential Steps In The Lathe Turning Process For Creating High-Quality Longboard Rollers?

To make high-quality longboard rollers, we start by choosing the right wood or material. Then, we put the material on a lathe, which is a machine that spins it. Next, we use sharp tools to shape the spinning material into smooth rollers. After that, we sand the rollers to make them even smoother. Finally, we finish them with a protective coating to keep them strong and nice-looking.

How Does The Choice Of Lathe And Tooling Affect The Precision And Finish Of Longboard Rollers?

Choosing the right lathe and tools is really important for making longboard rollers. A good lathe helps you shape the rollers more accurately. When you use sharp tools, the finish looks smoother. This makes the rollers roll better and feel nicer when you use them. So, if you want great longboard rollers, pick the best lathe and tools!

What Are Some Common Challenges Faced During The Lathe Turning Of Longboard Rollers And How Can They Be Mitigated?

When making longboard rollers on a lathe, you might face a few problems. One challenge is keeping the roller steady while it spins. To fix this, you can use better clamps or supports. Another issue is keeping the right shape. You can check the shape often as you work to make sure you’re doing it right. Also, using the right tools can help prevent mistakes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Longboard Rollers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about turning longboard rollers on a lathe: 1. **What is a lathe?** A lathe is a machine. It spins wood or metal to shape it. 2. **Why do we turn longboard rollers?** We turn longboard rollers to make them smooth and round. This helps the longboard roll better. 3. **What materials can we use?** You can use wood or plastic for longboard rollers. Both work well. 4. **How do you make sure they are even?** We measure carefully and watch while the lathe spins. This helps us make them just right. 5. **What tools do you need?** You need a lathe, some cutting tools, and safety gear. Safety gear keeps you safe while you work.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Commonly Used For Lathe Turning Longboard Rollers And What Are Their Advantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials for making longboard rollers include plastic, rubber, and hard woods. Plastic is lightweight and can be colorful. Rubber gives good grip and makes rides smoother. Hard woods are strong and look nice. Each material has its own benefits for riding comfort and durability.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Dimensions And Specifications For Longboard Rollers During The Lathe Turning Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right sizes for longboard rollers, you start by knowing what the longboard needs. You can measure other rollers or check guidelines for their sizes. Next, you decide how thick and wide you want them to be. Then, when using the lathe, you carefully adjust the settings to make sure they are shaped correctly. Always double-check your measurements as you work!”}},{“@type”: “Question”,”name”: “What Are The Essential Steps In The Lathe Turning Process For Creating High-Quality Longboard Rollers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make high-quality longboard rollers, we start by choosing the right wood or material. Then, we put the material on a lathe, which is a machine that spins it. Next, we use sharp tools to shape the spinning material into smooth rollers. After that, we sand the rollers to make them even smoother. Finally, we finish them with a protective coating to keep them strong and nice-looking.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Lathe And Tooling Affect The Precision And Finish Of Longboard Rollers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right lathe and tools is really important for making longboard rollers. A good lathe helps you shape the rollers more accurately. When you use sharp tools, the finish looks smoother. This makes the rollers roll better and feel nicer when you use them. So, if you want great longboard rollers, pick the best lathe and tools!”}},{“@type”: “Question”,”name”: “What Are Some Common Challenges Faced During The Lathe Turning Of Longboard Rollers And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making longboard rollers on a lathe, you might face a few problems. One challenge is keeping the roller steady while it spins. To fix this, you can use better clamps or supports. Another issue is keeping the right shape. You can check the shape often as you work to make sure you’re doing it right. Also, using the right tools can help prevent mistakes.”}}]}