Have you ever watched a lathe spin? It can be fascinating to see wood turn into a masterpiece. When it comes to lathe turning, two popular choices stand out: maple and oak. But which one is better? That’s a big question for many woodworkers.

Imagine crafting a beautiful bowl. You pick up a piece of oak and feel its strength. Then you try a piece of smooth maple. Each wood offers different colors and textures. What are the secrets behind these choices?

Did you know that maple often has a lighter shade while oak can be darker? This difference can change the look of your finished project. Many people love oak’s durability, but others swear by maple’s ease of use.

In this article, we will dive deep into lathe turning maple vs. oak. We’ll explore their features, advantages, and unique qualities. By the end, you’ll know which wood is right for your next project. Are you ready to discover the world of lathe turning?

Lathe Turning Maple Vs Oak Comparison: Which Is Better?

Understanding the Properties of Maple

Hardness and Density. Workability and Tool Wear.

Maple wood is quite interesting! It is known for its hardness and density, making it durable yet easy to shape. Maple is like the strong kid in gym class; it can handle a lot! However, this strength means you need to use sharper tools to work with it, or they might wear out faster. In comparison, oak is a bit tougher and may resist wear better. But hey, oak also likes to play hard to get with its grain patterns!

| Wood Type | Hardness | Density | Tool Wear |

|---|---|---|---|

| Maple | High | Medium | Wearable |

| Oak | Higher | High | Durable |

So choosing between maple and oak in lathe turning? It’s like picking between cookies and cake. Both are great, but each has its flavor!

Understanding the Properties of Oak

Hardness and Density. Workability and Tool Wear.

Oak is known for its strong and sturdy nature. It has a higher hardness than many woods, which makes it more durable. This also means it is more challenging to cut. The density of oak helps it resist wear from tools, but it can dull cutting edges faster. Here’s a simple breakdown:

- Hardness: Oak has a Janka hardness rating of about 1,300-1,400 lbf.

- Density: Oak’s density is around 47-58 lbs per cubic foot.

- Workability: It can be tricky to shape but is rewarding.

- Tool Wear: Expect faster dulling of tools due to its hardness.

Visual Characteristics of Maple and Oak

Color and Grain Patterns. Finishing Options and Appearance.

Maple and oak each have unique visual traits that make them special. Maple wood is lighter and smoother. Its color can range from creamy white to light brown. The grain is often straight and even. In contrast, oak is darker. It has a deep, golden hue with prominent grain patterns. This gives it a rich look. When finishing, maple shines brightly, while oak can appear rustic and warm.

- Maple: Light color, smooth grain

- Oak: Darker color, bold grain

- Finishing maple enhances brightness

- Finishing oak adds warmth

What are the finishing options for maple and oak?

Maple looks best with clear or light stains. Oak pairs well with dark stains for a rustic feel.

Turning Techniques for Maple

Speed and Feed Recommendations. Tool Selection and Maintenance.

Using the right speed and feed settings is crucial for turning maple. A slower speed helps prevent tearing. A good range is 1000-1500 RPM for roughing. When finishing, try 2000-3000 RPM. For feeding, aim for 1/8” to 1/4” per turn.

Tool choice matters, too. Sharp tools work best. They make cleaner cuts and reduce burns. Regularly sharpen and maintain your tools. This keeps your work smooth.

What is the best speed for turning maple?

The best speed for turning maple is between 1000-1500 RPM when roughing and 2000-3000 RPM for finishing.

Tips for Tool Selection:

- Use sharp chisels.

- Consider carbide tools for durability.

- Keep tools clean and rust-free.

Turning Techniques for Oak

Speed and Feed Recommendations. Tool Selection and Maintenance.

Turning oak requires careful planning. Start with speed and feed recommendations. Use a slower speed for oak than for softer woods. A traditional feed rate would be around 1/8 inch per revolution. This helps avoid burn marks.

Selecting the right tools is essential. Choose sharp tools made of high-speed steel or carbide for clean cuts. Regularly maintaining tools will keep them sharp. Check for nicks and dull edges often.

What are speed and feed recommendations for oak turning?

For oak turning, a slower speed and a feed rate of 1/8 inch per revolution work best.

Tool Selection Tips:

- Use sharp high-speed steel or carbide tools.

- Regularly check for nicks and dull edges.

- Keep tools clean for better performance.

Common Challenges in Turning Maple

Issues with Tearout and Splintering. Managing Moisture Content.

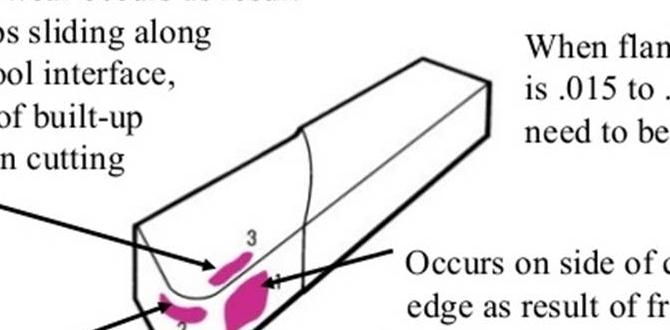

Turning maple can be tricky due to issues like tearout and splintering. This happens when the wood fibers break unevenly. To avoid this, use sharp tools and take light cuts. Moisture content also plays a big role. Too much moisture can make the wood hard to work with and affect the finish.

- Keep tools sharp to reduce tearout.

- Take light cuts for a smooth finish.

- Check moisture content often.

What causes tearout when turning maple?

Tearout happens because the wood fibers are weak or damaged. If your tools are dull, they can cause more tearout. It is important to check your tools before starting.

Common Challenges in Turning Oak

Issues with Grain Reaction. Challenges in Achieving a Smooth Finish.

Turning oak can be tricky due to its unique properties. One common problem is grain reaction. Oak has long fibers, which may tear instead of cut nicely. This can lead to rough surfaces. Achieving a smooth finish is another challenge. Oak often absorbs stains unevenly, affecting the final look. You may need more sanding and careful polishing to get it right.

What are some issues when turning oak?

- Grain Reaction: Oak fibers can tear and not cut smoothly.

- Smooth Finish: It absorbs finishes unevenly, requiring extra sanding.

Durability and Longevity of Maple vs Oak Products

Resistance to Wear and Tear. Impact on Finished Products’ Lifespan.

Maple and oak are both strong woods, but they have unique traits. Maple tends to resist dents and scratches better than oak, making it perfect for busy projects. On the other hand, oak shows off its toughness with a lovely grain. This beauty helps oak last longer, even under pressure. Imagine a battle of woods: maple, the scratch warrior, versus oak, the durability champion! Your final piece can shine for years, depending on your choice.

| Wood Type | Resistance to Wear | Impact on Lifespan |

|---|---|---|

| Maple | High | Long-lasting |

| Oak | Moderate | Very Long-lasting |

Cost Considerations: Maple vs Oak

Pricing Analysis of Material Cost. Value for Money in Finished Products.

Costs can vary between different types of wood. Maple tends to be less expensive than oak. This is great for woodworkers on a budget! Both woods, however, give great value in finished products. Whether you choose maple or oak, you’ll get sturdy, beautiful pieces. In a nutshell, oak can be pricier, but it has a rich look that many love. Here’s a quick price comparison:

| Wood Type | Average Cost per Board Foot | Value for Money |

|---|---|---|

| Maple | $3 – $5 | 👍 Good |

| Oak | $6 – $8 | 👍 Excellent |

So, if you’re looking for something that doesn’t break the bank but still looks great, maple might be your best bet! Just remember, more $$ doesn’t always mean better quality!

Case Studies: Projects Using Maple and Oak

Successful Maple Projects. Successful Oak Projects.

Maple and oak are both popular choices for woodworking projects, each bringing its unique flair. Successful projects using maple often include stunning bowls and elegant furniture. Maple’s fine grain gives a smooth finish, perfect for pieces that catch the eye. On the other hand, oak shines in sturdy items like tables and chairs. Its strength and grain make it ideal for pieces that withstand daily use. Who knew wood could have its own personality?

| Wood Type | Successful Projects |

|---|---|

| Maple | Bowls, Furniture |

| Oak | Tables, Chairs |

Expert Tips for Choosing Between Maple and Oak

Factors to Consider for Your Projects. Recommendations Based on Skill Level and Experience.

Choosing the right wood can shape your project’s success. Consider the following factors:

- Hardness: Maple is tougher than oak, making it great for durable items.

- Cost: Oak is often less expensive, making it good for budget projects.

- Appearance: Maple has a light color, while oak is darker with visible grain.

If you’re a beginner, start with oak for its ease. More experienced woodworkers may prefer maple due to its challenges. Each wood offers a unique touch, enhancing your creations.

What type of projects are best for maple and oak?

Maple is best for furniture, while oak is great for cabinets and flooring.

Conclusion

In summary, turning maple and oak on a lathe offers unique experiences. Maple is often smoother and easier to shape, while oak is strong and heavy. You might enjoy the lightness of maple for fine details, but oak is great for sturdy projects. Consider trying both types of wood. Each has its own charm! Keep learning and experimenting with your lathe skills.

FAQs

Here Are Five Related Questions Regarding The Comparison Of Lathe Turning Maple Versus Oak:

When you turn wood on a lathe, maple is usually smoother than oak. Maple has a fine grain, making it easier to shape. Oak is much harder, which can take more time. Both woods look nice, but maple can be shinier. If you want quick results, choose maple. If you like a stronger wood, go for oak.

Sure! Please provide the question you want me to answer.

What Are The Key Differences In Density And Hardness Between Maple And Oak When Turning Them On A Lathe?

When you turn wood on a lathe, maple is usually lighter than oak. This means oak is denser, which makes it harder to shape. Because of this hardness, oak can take longer to turn. Maple feels smoother and easier to work with, so you might finish your project faster. Overall, oak is tougher, while maple is softer and simpler to turn.

How Do The Grain Patterns Of Maple And Oak Affect The Final Aesthetic Of A Turned Wood Project?

The grain patterns of maple and oak give turned wood projects different looks. Maple has a smooth and light pattern. This makes projects look clean and simple. Oak has a more wavy and bold pattern. This can make projects look more rustic and interesting. Your choice between them will change how the final piece looks!

What Are The Advantages And Disadvantages Of Using Maple Versus Oak For Detailed Turnings, Such As Intricate Spindle Work?

Maple is great for detailed turnings because it is smooth and easy to shape. It has a light color that shows off intricate designs well. However, maple can be harder to find and is more expensive. Oak, on the other hand, is strong and widely available. It has a beautiful grain, but it can be rough, making detailed work trickier.

How Do The Machining Characteristics Of Maple And Oak Differ In Terms Of Tool Wear And Cutting Techniques During Lathe Turning?

Maple and oak are both types of wood, but they act differently when we cut them. When you turn maple on a lathe, it makes your tools wear down more slowly. This means you can cut for a longer time without needing to change your tools. Oak is tougher, so it might wear out your tools faster, and you might need to change your cutting method to be gentle.

What Finishing Options Work Best For Turned Pieces Made From Maple Compared To Those Made From Oak?

Maple is a light-colored wood, and it looks great with clear finishes. You can use oil or a clear varnish to show its natural beauty. Oak is darker and has more grain patterns. Stains work well on oak to bring out those designs. Both woods can be finished with wax for extra shine.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions Regarding The Comparison Of Lathe Turning Maple Versus Oak:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you turn wood on a lathe, maple is usually smoother than oak. Maple has a fine grain, making it easier to shape. Oak is much harder, which can take more time. Both woods look nice, but maple can be shinier. If you want quick results, choose maple. If you like a stronger wood, go for oak.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences In Density And Hardness Between Maple And Oak When Turning Them On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you turn wood on a lathe, maple is usually lighter than oak. This means oak is denser, which makes it harder to shape. Because of this hardness, oak can take longer to turn. Maple feels smoother and easier to work with, so you might finish your project faster. Overall, oak is tougher, while maple is softer and simpler to turn.”}},{“@type”: “Question”,”name”: “How Do The Grain Patterns Of Maple And Oak Affect The Final Aesthetic Of A Turned Wood Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The grain patterns of maple and oak give turned wood projects different looks. Maple has a smooth and light pattern. This makes projects look clean and simple. Oak has a more wavy and bold pattern. This can make projects look more rustic and interesting. Your choice between them will change how the final piece looks!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using Maple Versus Oak For Detailed Turnings, Such As Intricate Spindle Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Maple is great for detailed turnings because it is smooth and easy to shape. It has a light color that shows off intricate designs well. However, maple can be harder to find and is more expensive. Oak, on the other hand, is strong and widely available. It has a beautiful grain, but it can be rough, making detailed work trickier.”}},{“@type”: “Question”,”name”: “How Do The Machining Characteristics Of Maple And Oak Differ In Terms Of Tool Wear And Cutting Techniques During Lathe Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Maple and oak are both types of wood, but they act differently when we cut them. When you turn maple on a lathe, it makes your tools wear down more slowly. This means you can cut for a longer time without needing to change your tools. Oak is tougher, so it might wear out your tools faster, and you might need to change your cutting method to be gentle.”}},{“@type”: “Question”,”name”: “What Finishing Options Work Best For Turned Pieces Made From Maple Compared To Those Made From Oak?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Maple is a light-colored wood, and it looks great with clear finishes. You can use oil or a clear varnish to show its natural beauty. Oak is darker and has more grain patterns. Stains work well on oak to bring out those designs. Both woods can be finished with wax for extra shine.”}}]}