Have you ever watched a skilled craftsman create beautiful wooden pieces? It’s fascinating to see how they shape each item with precision and care. But what if you could speed up that process? What if you could lathe turn multiple pieces at once?

Imagine a magical machine that can work on several items at the same time. This means less waiting and more time for fun projects. It’s like doubling your output without doubling your effort!

Lathe turning multiple pieces at once offers amazing possibilities. You can make identical parts quickly or try out different designs on several items. This method amazes both new and experienced woodworkers. They all love how it makes their work easier and faster.

Have you ever thought about how many different items a lathe can create? From beautiful chair legs to unique bowls, the options are endless. You might even find yourself inspired to try it out!

Lathe Turning Multiple Pieces At Once: A Comprehensive Guide

Lathe Turning Multiple Pieces at Once

Lathe turning allows you to create several pieces in one go. Imagine finishing multiple identical parts quickly! This method saves time and enhances productivity. You can use special tools and setups to hold several workpieces together. This technique is perfect for making lots of the same item, like furniture knobs or metal shafts. It’s efficient, helping both hobbyists and professionals alike. Did you know that mastering this skill can boost your projects’ quality while cutting down your working hours?Benefits of Turning Multiple Pieces Simultaneously

Increased efficiency and productivity.. Costeffectiveness in mass production settings..Turning many pieces at the same time helps workers get more done quickly. This process saves time and makes work smoother. It also means less money spent on materials, which is great for businesses. Here are some key benefits:

- Increased efficiency: Doing various pieces together cuts down on machine setup time.

- Boosted productivity: Workers can create more items in less time.

- Cost-effectiveness: More pieces mean lower costs per item.

This approach helps companies grow and succeed in a crowded market.

Why is it good to turn multiple pieces at once?

Turning multiple pieces saves time and reduces costs, making production faster and more economical. Many companies enjoy these advantages in today’s competitive economy.

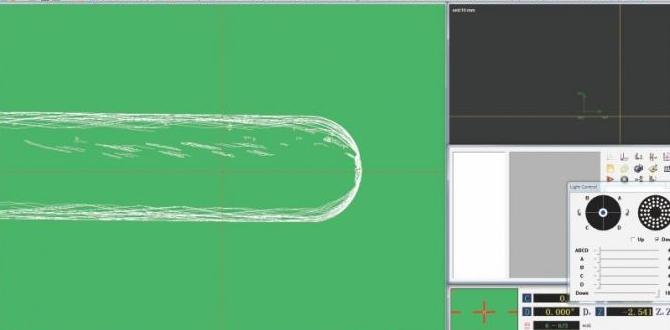

Techniques for Effective Multi-Piece Lathe Turning

Best practices for setting up the workpieces.. Ideal tooling and fixtures for enhanced turning..To turn multiple pieces using a lathe, set up your workpieces properly. Keep them aligned and secure. Use strong fixtures to hold everything in place. Here are some best practices:

- Check your workpieces for equal sizes.

- Ensure the lathe is level.

- Choose appropriate tooling for each material.

Using the right tools boosts efficiency and quality. Perfect your setup, and you’ll see great results!

What are the best tools for lathe turning multiple pieces?

The best tools include carbide inserts, quick-change tool holders, and steady rest for stability. These tools help make the job easier and faster.

Common Applications of Multi-Piece Lathe Turning

Industries that benefit from this technique (automotive, aerospace, etc.).. Examples of components typically produced using this method..Many industries love using multipiece lathe turning to speed up their production. The automotive and aerospace sectors are two big users of this technique. They produce parts like engine components and airplane fittings. Why make one part at a time when you can make a bunch at once? It saves time and money, allowing companies to keep up with demand and maybe even buy more coffee for their workers!

| Industry | Common Components |

|---|---|

| Automotive | Engine Blocks, Axles |

| Aerospace | Fittings, Brackets |

Challenges in Multi-Piece Lathe Turning

Potential issues related to precision and quality control.. Strategies to mitigate common challenges..Multipiece lathe turning can feel like juggling with too many balls. The main struggles are precision and quality control. When you work on several pieces at once, it’s easy for errors to creep in. A small mistake can create a big mess. Quality drops, and nobody wants that! To tackle these issues, you can use tools like better gauges and regular checks. It’s like keeping an eye on a mischievous puppy—stay alert, and everyone stays happy!

| Challenge | Solution |

|---|---|

| Poor Precision | Frequent measurements |

| Quality Control | Regular checks |

Future Trends in Lathe Turning Technology

Innovations shaping the future of multipiece lathe turning.. Predictions for advancements in automation and efficiency..Exciting new changes are coming in lathe turning technology! Innovations will help us make multiple pieces at once more easily and quickly. Here are some key advancements to look forward to:

- Smart machines: Robots will work alongside human workers.

- Faster tools: New tools will cut materials quicker.

- Better software: Advanced programs will improve production speed.

Expect great improvements in automation and efficiency. These developments will make factories more productive. In fact, it is predicted that overall production could increase by up to 30% over the next decade. Isn’t that amazing?

What advancements are expected in lathe turning technology?

We can expect smarter machines, faster tools, and better software in lathe turning technology.Comparative Analysis with Single-Piece Turning

When to choose multipiece over singlepiece turning.. Cost and time considerations for each method..Choosing between turning one piece and multiple pieces depends on your needs. If time and cost matter, multipiece turning often wins. It speeds up production and reduces material waste. But single-piece turning might suit custom or detailed work better. Keep these points in mind:

- Cost: Multipiece setups have higher initial costs but save money in bulk.

- Time: Turning multiple pieces means less time spent per item.

Think about your project goals. Understanding these factors helps you pick the right method.

When should I choose multipiece over singlepiece turning?

Choose multipiece turning for faster production and lower costs when making many identical items. For custom jobs or unique designs, single-piece turning is the better choice.

Key Takeaways for Manufacturers

Summary of essential considerations for implementing multipiece turning.. Final thoughts on maximizing production capabilities..Manufacturers should think about a few key points before embracing multipiece lathe turning. First, ensure your setup can handle multiple parts efficiently. This means investing in the right tools and training staff to use them effectively. Also, remember that good organization is vital. A confused factory is like a cat in a dog show—out of place and not very productive! Finally, always measure your results. Tracking performance helps find ways to boost production. In short, plan wisely to really rev up your manufacturing!

| Consideration | Benefit |

|---|---|

| Investing in the right tools | Improves efficiency |

| Training staff | Enhances skillset |

| Organization | Boosts productivity |

| Performance tracking | Identifies improvements |

Conclusion

In summary, lathe turning multiple pieces at once can save time and improve accuracy. This method helps you create identical items quickly. We can use jigs to hold several pieces securely while we work. To learn more, consider exploring videos or guides on lathe techniques. With practice, you can master this skill and enhance your projects!FAQs

What Are The Advantages Of Using A Lathe To Turn Multiple Pieces Simultaneously Rather Than One At A Time?Using a lathe to turn many pieces at once saves time. You can make more things quickly, which is great for big projects. It also helps keep the pieces the same size since they are done together. Plus, it’s easier to set up the machine just once. This way, we can work faster and be more efficient!

What Specific Setup Or Tooling Is Required For Effective Batch Turning On A Lathe?To do batch turning on a lathe, you need a few important tools. First, you need a lathe machine that spins the metal piece. You also need cutting tools to shape the metal. A tool holder helps keep the cutting tools in place. Finally, you should have measuring tools to check the size of your pieces.

How Does The Material Type Affect The Feasibility Of Turning Multiple Pieces At Once?The type of material can change how easy it is to turn several pieces at once. Hard materials can be tough to shape, making it harder to do many items together. Soft materials are usually easier to work with, allowing you to turn more pieces at the same time. So, we need to think about material hardness when deciding how many pieces to turn.

What Are The Common Challenges Faced When Attempting To Turn Multiple Pieces On A Lathe, And How Can They Be Mitigated?When we turn multiple pieces on a lathe, we might face some challenges. One problem is making sure all the pieces are the same size. To fix this, we can measure each piece carefully. Another issue is keeping the tools sharp. We should check and sharpen our tools often. Finally, it’s important to stay focused so we don’t make mistakes. Taking breaks helps us stay sharp.

Can You Describe The Process For Ensuring Consistent Quality And Precision When Turning Multiple Pieces Concurrently?To ensure quality and precision when making several pieces at once, we start by preparing our tools. We check that everything is clean and sharp. Next, we set up each piece carefully, making sure they all sit in the same spot. While we work, we measure each piece to confirm they match. Finally, we inspect everything before finishing to catch any mistakes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Lathe To Turn Multiple Pieces Simultaneously Rather Than One At A Time? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a lathe to turn many pieces at once saves time. You can make more things quickly, which is great for big projects. It also helps keep the pieces the same size since they are done together. Plus, it’s easier to set up the machine just once. This way, we can work faster and be more efficient!”}},{“@type”: “Question”,”name”: “What Specific Setup Or Tooling Is Required For Effective Batch Turning On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To do batch turning on a lathe, you need a few important tools. First, you need a lathe machine that spins the metal piece. You also need cutting tools to shape the metal. A tool holder helps keep the cutting tools in place. Finally, you should have measuring tools to check the size of your pieces.”}},{“@type”: “Question”,”name”: “How Does The Material Type Affect The Feasibility Of Turning Multiple Pieces At Once? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of material can change how easy it is to turn several pieces at once. Hard materials can be tough to shape, making it harder to do many items together. Soft materials are usually easier to work with, allowing you to turn more pieces at the same time. So, we need to think about material hardness when deciding how many pieces to turn.”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced When Attempting To Turn Multiple Pieces On A Lathe, And How Can They Be Mitigated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we turn multiple pieces on a lathe, we might face some challenges. One problem is making sure all the pieces are the same size. To fix this, we can measure each piece carefully. Another issue is keeping the tools sharp. We should check and sharpen our tools often. Finally, it’s important to stay focused so we don’t make mistakes. Taking breaks helps us stay sharp.”}},{“@type”: “Question”,”name”: “Can You Describe The Process For Ensuring Consistent Quality And Precision When Turning Multiple Pieces Concurrently? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure quality and precision when making several pieces at once, we start by preparing our tools. We check that everything is clean and sharp. Next, we set up each piece carefully, making sure they all sit in the same spot. While we work, we measure each piece to confirm they match. Finally, we inspect everything before finishing to catch any mistakes.”}}]}