Have you ever wondered how musical instruments are made? For many, this magical process starts with lathe turning. It’s a special way to shape wood or metal into beautiful parts for instruments.

Imagine the smooth sound of a violin or the bright notes of a trumpet. Each piece plays an important role in making music come alive. But how do makers get those perfect shapes? That’s where lathe turning comes in!

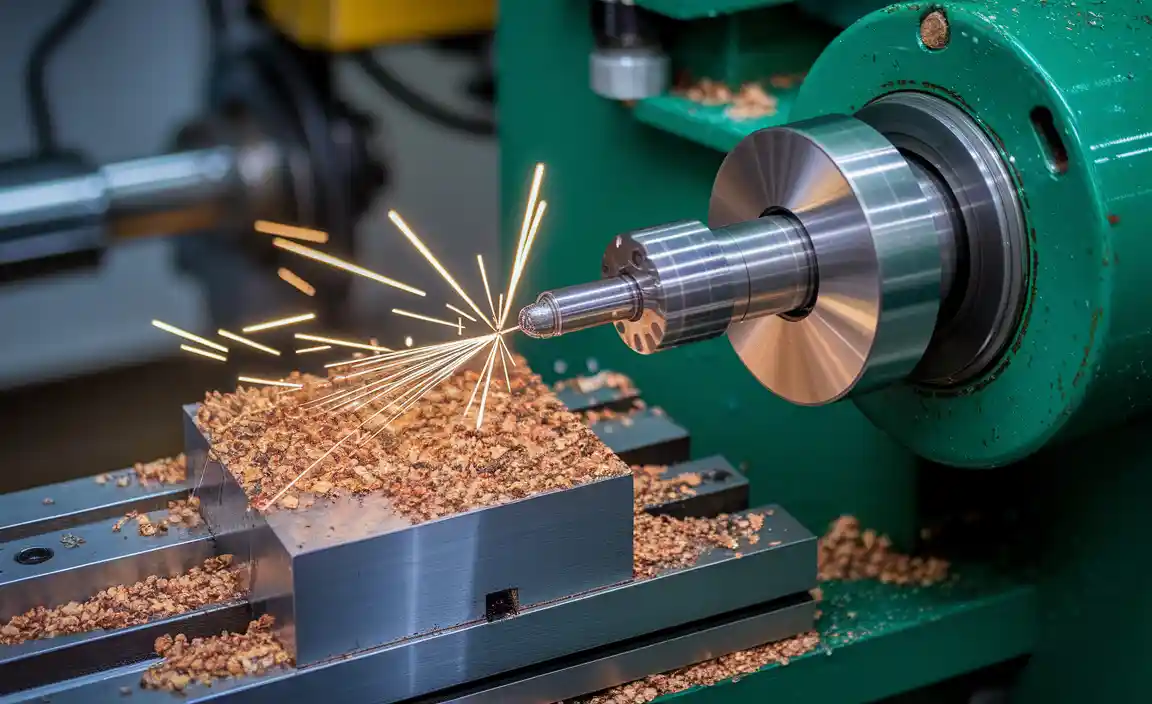

Lathe turning is like a dance. The tool spins quickly while the wood or metal stays still. It removes small bits to create curves and edges that fit together just right. This technique helps build everything from guitar bodies to flute keys.

Did you know that some of the finest music comes from instruments made with lathe turning? Musicians everywhere rely on these carefully crafted parts. Let’s explore how lathe turning shapes the world of musical instruments and why it is so exciting!

Lathe Turning Musical Instrument Parts: Crafting With Precision

Understanding Lathe Turning Basics

Definition and significance of lathe turning in musical instrument manufacturing. Key components of a lathe and their functions in the turning process.

Lathe turning is a method used to make musical instrument parts. It shapes wood or metal for items like drum shells or flute tubes. This process is important because it helps create smooth and precise designs. Each lathe has key parts that allow it to function well:

- Headstock: This holds the spinning tool and keeps it steady.

- Tailstock: It supports the other end of the work material, making turning easier.

- Bed: The flat base where everything rests, providing support and alignment.

- Tool Rest: It holds the cutting tool in place to ensure accuracy.

Understanding these components is essential for crafting high-quality musical instruments.

Why is lathe turning important in music?

Lathe turning ensures that parts of musical instruments are shaped perfectly. This perfect shape leads to better sound quality and easier playability. The process is key for both beginners and expert musicians.

Essential Tools and Materials for Lathe Turning

List of tools required for lathe turning musical instrument parts. Recommended materials for durability and sound quality in instruments.

Creating musical instrument parts on a lathe requires some neat tools and solid materials. First, you’ll need a lathe itself, of course! A good quality set of chisels and files helps in shaping the parts just right. Don’t forget to grab some safety goggles, so your eyes don’t get any surprises! For durability and great sound, materials like maple and mahogany are ideal. They look good and sound even better!

| Tool/Material | Purpose |

|---|---|

| Lathe | Main tool for turning |

| Chisels | For shaping and carving |

| Files | To smooth surfaces |

| Maple | Durable wood for sound quality |

| Mahogany | Rich tone and appearance |

Techniques for Effective Lathe Turning

Stepbystep techniques for shaping common instrument parts (e.g., knobs, mouthpieces). Tips for achieving precision and consistency in each turning project.

To create amazing parts like knobs and mouthpieces, you need some smart tricks. First, always measure twice and cut once—this saves time and ensures you won’t end up with a triangle instead of a perfect circle! Next, use sharp tools to get smooth finishes. It’s like trying to slice butter with a dull knife—waaaay too much effort! Lastly, practice is key. Remember, even Mozart didn’t play symphonies on the first try!

| Technique | Description |

|---|---|

| Measuring | Measure parts carefully to avoid mistakes. |

| Sharp Tools | Use sharp lathe tools for clean cuts. |

| Practice | Keep practicing for perfecting your skills! |

Safety Precautions While Lathe Turning

Importance of safety gear and proper workspace setup. Common hazards in lathe turning and how to avoid them.

Working with a lathe can be exciting, but safety is key. Always wear safety gear like goggles and gloves. A clean workspace helps too. Keep tools organized to avoid accidents. Danger lurks in flying debris and sharp blades. Stay focused and avoid loose clothing. Follow these tips to stay safe while creating:

- Wear safety glasses.

- Keep your area tidy.

- Secure your materials tightly.

- Keep hands clear of moving parts.

What are common hazards in lathe turning?

Common hazards include flying wood pieces and sharp edges. Ensure you take necessary precautions to protect yourself.

Case Studies: Successful Musical Instrument Parts Made by Lathe Turning

Examples of notable instruments crafted using lathe turning techniques. Insights from expert luthiers and musicians on the impact of quality latheturned parts.

Many famous musical instruments owe their unique sound to lathe turning. For example, flutes and violins have parts made this way. Luthiers, or instrument makers, share that quality lathe-turned parts make a big difference. Here are a few notable examples:

- Guitar necks, offering perfect shape for play quality.

- Trumpet valves, improving performance and sound.

- Clarinet mouthpieces, allowing for better tone and control.

Experts agree that lathe turning brings precision and enhances the music we hear. Musicians feel proud to play instruments crafted with care.

Future Trends in Lathe Turning for Musical Instruments

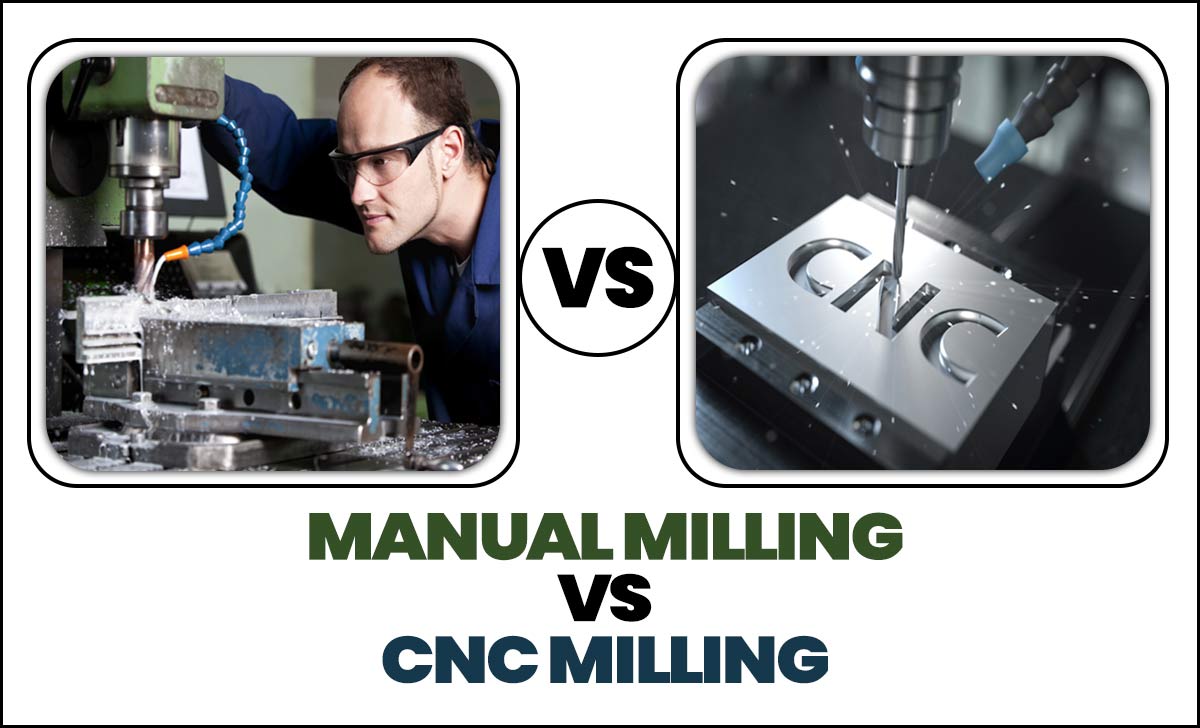

Innovations in technology affecting lathe turning practices (e.g., CNC lathes). Predictions on the evolving role of lathe turning in instrument design and production.

New tools are changing how we make musical instrument parts. CNC lathes, for example, allow for precise cuts and designs. This technology saves time and improves quality. As we move forward, lathe turning will play a key role in creating unique sounds and styles for instruments. We can expect more creativity and innovation from instrument makers.

How is technology changing lathe turning for musical instruments?

Technology is making lathe turning faster and more accurate. CNC machines help makers cut and mold parts perfectly, leading to better instruments with great sound.

Key Innovations:

- Improved precision with CNC lathes

- Faster production times

- More creative designs for unique sounds

Resources for Learning and Mastering Lathe Turning

Recommended books, online courses, and workshops for aspiring craftsmen. Communities and forums for sharing knowledge and experiences in lathe turning.

Learning lathe turning can be a fun journey. There are helpful books, online courses, and workshops out there. These resources teach aspiring craftsmen how to shape parts for musical instruments and more. Joining online communities and forums is also a great idea. You can share tips and stories, making new friends who love lathe turning just as much as you do. Here’s a list of useful resources:

| Type | Resource | Description |

|---|---|---|

| Book | “The Lathe Book” | A beginner’s guide packed with tips and tricks. |

| Course | Online Lathe Turning 101 | Interactive lessons perfect for newbies. |

| Workshop | Local Maker Space | Hands-on practice in your community. |

| Forum | Lathe Lovers Unite | A place to ask questions and share ideas. |

With these resources, you’ll be turning musical instrument parts in no time! Remember, even the best lathe turners were once beginners. Keep spinning and having fun!

Conclusion

In summary, lathe turning is essential for making musical instrument parts. It helps create precise and smooth shapes. By learning this skill, you can craft beautiful instruments. We encourage you to explore lathe turning further. Try practicing with simple projects. Discover how this technique can enhance your music-making journey. Happy creating!

FAQs

What Are The Different Types Of Lathe Machines Used For Turning Musical Instrument Parts, And How Do They Vary In Functionality?

There are different types of lathe machines for making parts of musical instruments. A wood lathe helps shape wood pieces like drumsticks or flute bodies. A metal lathe works with metal to create parts for brass instruments like trumpets. CNC (Computer Numerical Control) lathes use computers to make very precise cuts. Each type has its own special job, but all help make beautiful music parts!

How Do Wood Selection And Grain Orientation Affect The Acoustics And Performance Of Lathe-Turned Musical Instrument Components?

The type of wood you choose affects how well a musical instrument sounds. Different woods can make different loudness and tone. Grain orientation, which is how the lines in the wood go, also matters. If the lines run in the right way, the sound travels better and makes the music clearer. So, picking the right wood and checking the grain help create better-sounding instruments.

What Are The Key Techniques In Lathe Turning That Are Specific To Crafting Components For Instruments Like Violins, Flutes, Or Drums?

When we turn wood on a lathe to make musical instruments, we use some special techniques. First, we shape the wood into the right size and form, making sure it fits perfectly. Next, we carefully smooth the surfaces so the instruments sound nice when played. We also focus on details, like curves and edges, to make them look pretty. Lastly, we check how each part fits together to ensure it works well in the instrument.

What Safety Precautions Should Be Taken When Lathe Turning Parts For Musical Instruments To Avoid Injuries And Ensure Quality Production?

When using a lathe to make parts for musical instruments, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught in the machine. Make sure to keep your hands away from moving parts to avoid getting hurt. Always check that tools are in good shape and working well before you start. Finally, pay close attention while you work to ensure everything is done safely and correctly.

How Does The Design Process For Lathe-Turned Musical Instrument Parts Integrate With Other Stages Of Instrument Making, Such As Assembly And Finishing?

When we design parts for musical instruments on a lathe, we think about how they fit together. These parts must be the right size and shape so they can be easily assembled. After turning the parts, we move on to put the instrument together. Finally, we finish it by sanding and polishing to make it look nice and work well. Each step is connected, helping create a great musical instrument!