Have you ever wondered how machines create unique shapes? Take a moment to think about the fascinating world of lathe turning. This process helps make special spindle shapes that are not round. It may seem tricky, but it’s an exciting craft!

Imagine a sculptor, shaping clay into different forms. In a similar way, a lathe can transform simple materials into non-round shapes. These shapes are used in many everyday items, like furniture and toys. That’s pretty cool, right?

Did you know that lathe turning can create anything from quirky knobs to parts for complex machines? It all starts with a basic idea and the right tools. Once you understand the process, you can make incredible designs. Are you ready to discover the art of lathe turning non-round spindle shapes?

Lathe Turning Non-Round Spindle Shapes For Precision Engineering

Importance of Non-Round Spindle Shapes

Applications in various industries (automotive, aerospace, etc.). Benefits of using nonround shapes over traditional round profiles.

Non-round spindle shapes play a big role in many industries. In automotive and aerospace, these unique shapes help machines run better. They can fit into tighter spaces, saving weight and making things more efficient. Why stick to boring circles when you can have cool shapes? With non-round designs, parts can work together like a perfect puzzle, leading to less wear and tear over time.

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Engine components | Increased efficiency |

| Aerospace | Aircraft parts | Weight reduction |

Choosing non-round over round shapes isn’t just smart; it’s also a little exciting! Characters like Batman wouldn’t stick to basic shapes, right? So, why should we?

Tools and Equipment for Non-Round Turning

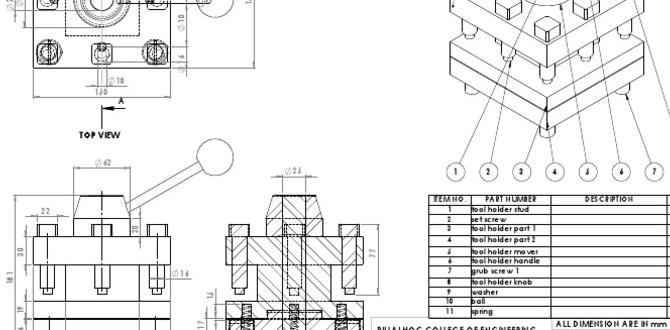

Essential tools and accessories for achieving nonround shapes. Recommended lathes and attachments for enhanced performance.

Getting the right tools can make turning those funky non-round shapes a breeze! To start, a solid lathe is a must. Think about one with adjustable speeds for better control. Don’t forget about special attachments, like eccentric turners, to help you achieve those quirky contours. Measuring tools are vital too — no one wants to turn a peanut when they meant to craft a perfect oval! Check out this handy table for the best gear:

| Tools/Equipment | Purpose | Recommended Types |

|---|---|---|

| Lathe | Basic tool for turning | Mini Lathes, Benchtop Lathes |

| Eccentric Turner | Shapes that are not circular | Adjustable/Fixed types |

| Measuring Tools | Ensures the right dimensions | Calipers, Rulers |

Techniques for Turning Non-Round Spindles

Stepbystep guide for setting up the lathe for nonround turning. Tips for achieving precision and accuracy in shape creation.

To turn those tricky non-round spindles, begin by setting up your lathe carefully. First, check the alignment—this is like making sure your ice cream cone won’t topple over. Next, secure your workpiece with the right chuck. For precision, use a caliper to measure and mark points evenly around the spindle. Don’t worry if it looks funny at first! With practice, you’ll be a funny-looking spindle turning pro.

| Steps | Tips |

|---|---|

| 1. Align the lathe | Use a level, like a tightrope walker! |

| 2. Secure the workpiece | Double-check with a wrench! |

| 3. Measure points | Make your marks neat; try not to doodle! |

For accuracy, take your time and ensure everything is snug. If your piece wobbles, it won’t look good. Remember: practice makes perfect. Even the best started out making weird shapes! So don’t be shy; let your creativity shine!

Common Challenges and Solutions

Identification of typical issues faced when turning nonround shapes. Troubleshooting techniques and best practices to overcome challenges.

Turning non-round spindle shapes can bring some challenges. Common issues include vibrations, uneven cuts, and tool wear. These problems can lead to poor finishes or even accidents. Here are some effective ways to overcome these challenges:

- Check the machine setup for mistakes.

- Use proper cutting speeds and feeds.

- Select the right tool for the job.

- Regularly inspect your tools for damage.

By staying alert and using these tips, mistakes can be minimized.

What are common problems in lathe turning?

Common problems include vibrations, tool wear, and uneven cuts. Identifying these early can help prevent bigger issues.

How can I improve my turning skills?

Practice regularly, learn from mistakes, and ask for advice from experts.

Case Studies of Successful Non-Round Spindle Projects

Examples of industries successfully utilizing nonround spindle shapes. Analysis of design considerations and implementation strategies.

Many businesses are turning heads with their non-round spindle projects. For example, the automotive industry uses these designs for parts like crankshafts. These shapes help improve performance and efficiency. The medical field is another winner, using non-round spindles in machines that make precise cuts. When designing, engineers consider factors like strength and balance. They know that a spindle that looks like a pretzel doesn’t just hold parts; it moves them smoothly, and that’s no joke!

| Industry | Application |

|---|---|

| Automotive | Crankshafts |

| Medical | Surgical Tools |

| Aerospace | Engine Parts |

Safety Measures and Best Practices

Essential safety protocols when working on a lathe. Best practices for maintaining equipment and ensuring worker safety.

Using a lathe can be fun, but safety comes first. Always wear safety glasses to protect your eyes. Keep long hair tied back, and avoid loose clothing. This helps keep you safe while working. It’s also key to maintain your lathe. Regularly check for loose parts and keep it clean. This ensures it works well and reduces accidents. Remember, safety is about being smart and careful!

What are the essential safety protocols when working on a lathe?

Essential safety protocols include wearing protective gear, staying alert, and keeping your workspace tidy. Always follow the manufacturer’s instructions and never rush your work.

Best Practices

- Wear safety goggles.

- Keep tools organized.

- Check equipment regularly.

- Be aware of your surroundings.

Future Trends in Non-Round Shape Turning

Innovations in technology influencing lathe operations. Predictions for the future of nonround spindle applications in manufacturing.

New technology is changing how we turn non-round shapes on lathes. Cool machines are popping up, making it easier and quicker to create complex shapes. In the future, I predict we’ll see even more clever designs in manufacturing. These new shapes will be used in everyday things, from toys to car parts. The possibilities are endless! Imagine a corncob-shaped gear—now that’s a real head-turner! Here’s a peek at what’s coming:

| Innovation | Impact on Manufacturing |

|---|---|

| Smart Lathes | Faster production times! |

| 3D Printing Integration | More creative shapes possible! |

| Advanced Algorithms | Less waste and more accuracy! |

Stay tuned, because the future looks bright (and a little wobbly) for turning those quirky shapes!

Conclusion

In conclusion, lathe turning non-round spindle shapes is an exciting skill. It allows you to create unique designs for various projects. You can make things like handles or decorative pieces. Practice is essential, so start with simple shapes and gradually try more complex ones. For more tips and techniques, consider reading more about woodworking and lathe techniques!

FAQs

Here Are Five Related Questions On The Topic Of Lathe Turning Non-Round Spindle Shapes:

Lathe turning is a way to shape materials like wood or metal. We can use a lathe to make round shapes, but it can also make non-round shapes. This means we can create different designs, like squares or triangles, instead of just circles. It’s a fun way to make unique pieces for projects!

Sure! Please provide the question you’d like me to answer, and I’ll help you with that.

What Are The Common Techniques Used To Create Non-Round Spindle Shapes On A Lathe?

To create non-round shapes on a lathe, we can use a few techniques. One way is called “offset turning,” where you shift the wood slightly to make it uneven. Another method is using a “template.” We can follow a shape drawn out on paper, and cut the wood to match. Lastly, we can also use “freehand” techniques, where you shape the wood by eye. These methods help make cool shapes beyond just circles!

How Does The Setup And Tool Selection Differ When Turning Non-Round Shapes Compared To Traditional Round Shapes?

When turning non-round shapes, like squares or rectangles, we need special tools. These tools can create flat sides instead of just round surfaces. You also have to set up the machine differently, so the piece doesn’t move around. This helps us make the right shape without messing it up. For round shapes, it’s easier because we usually use standard tools and setups.

What Are The Advantages And Challenges Of Machining Non-Round Spindles In Various Materials?

Machining non-round spindles means shaping them into fun forms, like ovals or squares. One advantage is that they can fit better in special machines, helping them work well. However, making these shapes can be tricky. You need good tools and skills to avoid mistakes. Plus, some materials, like metal or plastic, can be harder to shape than others.

Can Cnc Lathes Be Effectively Utilized For Turning Non-Round Spindle Shapes, And If So, What Programming Considerations Are Needed?

Yes, we can use CNC (Computer Numerical Control) lathes to create shapes that aren’t round. To do this, we need to plan carefully. You must write special instructions or codes that guide the machine. These instructions help the lathe know how to move and shape the material correctly. With the right programming, we can make many different cool shapes!

What Types Of Applications And Industries Commonly Require Non-Round Spindle Shapes, And What Are Their Specific Design Requirements?

Non-round spindle shapes are used in many industries like automotive and medical devices. Cars often need special shapes for better movement and connection parts. In medicine, devices like drills need unique designs to work accurately. These shapes must fit tightly and move smoothly. We also need to think about strength and durability to keep them safe and effective.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Turning Non-Round Spindle Shapes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe turning is a way to shape materials like wood or metal. We can use a lathe to make round shapes, but it can also make non-round shapes. This means we can create different designs, like squares or triangles, instead of just circles. It’s a fun way to make unique pieces for projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll help you with that.”}},{“@type”: “Question”,”name”: “What Are The Common Techniques Used To Create Non-Round Spindle Shapes On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create non-round shapes on a lathe, we can use a few techniques. One way is called offset turning, where you shift the wood slightly to make it uneven. Another method is using a template. We can follow a shape drawn out on paper, and cut the wood to match. Lastly, we can also use freehand techniques, where you shape the wood by eye. These methods help make cool shapes beyond just circles!”}},{“@type”: “Question”,”name”: “How Does The Setup And Tool Selection Differ When Turning Non-Round Shapes Compared To Traditional Round Shapes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When turning non-round shapes, like squares or rectangles, we need special tools. These tools can create flat sides instead of just round surfaces. You also have to set up the machine differently, so the piece doesn’t move around. This helps us make the right shape without messing it up. For round shapes, it’s easier because we usually use standard tools and setups.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Challenges Of Machining Non-Round Spindles In Various Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machining non-round spindles means shaping them into fun forms, like ovals or squares. One advantage is that they can fit better in special machines, helping them work well. However, making these shapes can be tricky. You need good tools and skills to avoid mistakes. Plus, some materials, like metal or plastic, can be harder to shape than others.”}},{“@type”: “Question”,”name”: “Can Cnc Lathes Be Effectively Utilized For Turning Non-Round Spindle Shapes, And If So, What Programming Considerations Are Needed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we can use CNC (Computer Numerical Control) lathes to create shapes that aren’t round. To do this, we need to plan carefully. You must write special instructions or codes that guide the machine. These instructions help the lathe know how to move and shape the material correctly. With the right programming, we can make many different cool shapes!”}},{“@type”: “Question”,”name”: “What Types Of Applications And Industries Commonly Require Non-Round Spindle Shapes, And What Are Their Specific Design Requirements?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Non-round spindle shapes are used in many industries like automotive and medical devices. Cars often need special shapes for better movement and connection parts. In medicine, devices like drills need unique designs to work accurately. These shapes must fit tightly and move smoothly. We also need to think about strength and durability to keep them safe and effective.”}}]}