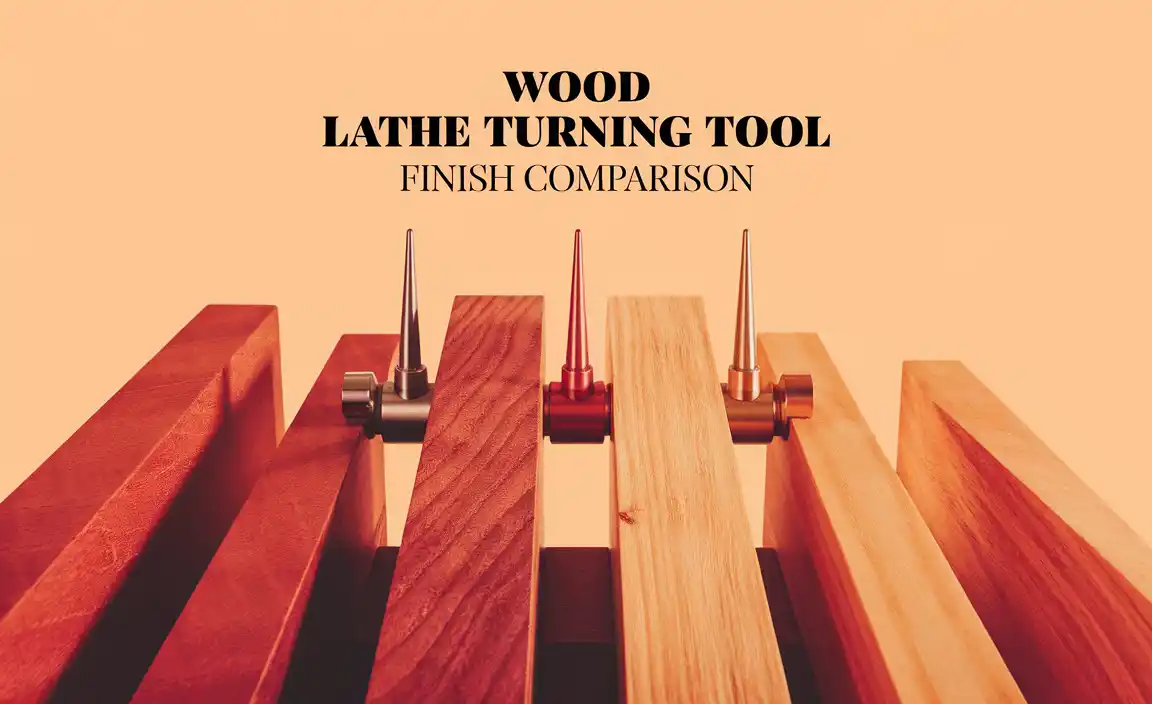

Lathe Turning Screw Chuck Mounting Steps Explained Step-By-Step

Understanding Screw Chucks

Definition and purpose of screw chucks in lathe turning.. Types of screw chucks available in the market..

A screw chuck is a tool used in lathe turning. It holds and secures materials tightly. This helps in shaping and cutting items precisely. There are different types of screw chucks available, such as:

- Self-Centering Chucks: These automatically center the workpiece.

- Independent Chucks: Each jaw moves separately for custom gripping.

- Collet Chucks: They use sleeves to hold smaller pieces firmly.

Choosing the right screw chuck makes a big difference in your work. It leads to better results and smoother finishes.

What is the purpose of screw chucks in lathe turning?

The main purpose of screw chucks is to secure the workpiece while you shape it on the lathe. This allows for accurate cutting and shaping, making your projects easier and faster.

What types of screw chucks are available?

There are a few key types of screw chucks:

- Self-Centering Chucks – Center the workpiece automatically.

- Independent Chucks – Adjust each jaw separately.

- Collet Chucks – Secure small items effectively.

Essential Tools and Materials

List of necessary tools required for mounting a screw chuck.. Recommended materials for optimal performance and safety..

To mount a screw chuck, you will need specific tools and materials. Here’s a list to help you get started:

- Wrench: For tightening the chuck.

- Drill: Used for creating accurate holes.

- Screwdriver: For securing the chuck.

- Safety goggles: To protect your eyes.

- Measuring tape: For precise measurements.

Using the right materials ensures smooth and safe operation. Always check for compatibility with your lathe machine to improve performance.

What are the necessary tools for lathe turning?

The tools include a wrench, drill, screwdriver, safety goggles, and measuring tape.

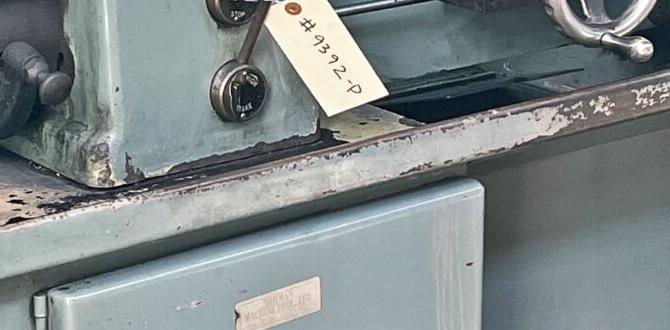

Preparing the Lathe Machine

Steps to clean and check your lathe machine before mounting.. Importance of ensuring machine stability and safety..

Before using the lathe machine, it’s essential to make sure it is clean and functioning properly. Here are key steps to follow:

- Wipe down the machine to remove dust and debris.

- Check all moving parts for smooth operation.

- Inspect the power cord and connections for damage.

Making sure your machine is stable and safe helps prevent accidents. Regular checks can keep the lathe running well and extend its lifespan. Remember, a clean machine works better!

Why is it important to prepare the lathe machine?

Preparing the lathe machine helps avoid mishaps and ensures smooth operation. A well-kept machine not only lasts longer but also works more effectively, making your projects much easier.

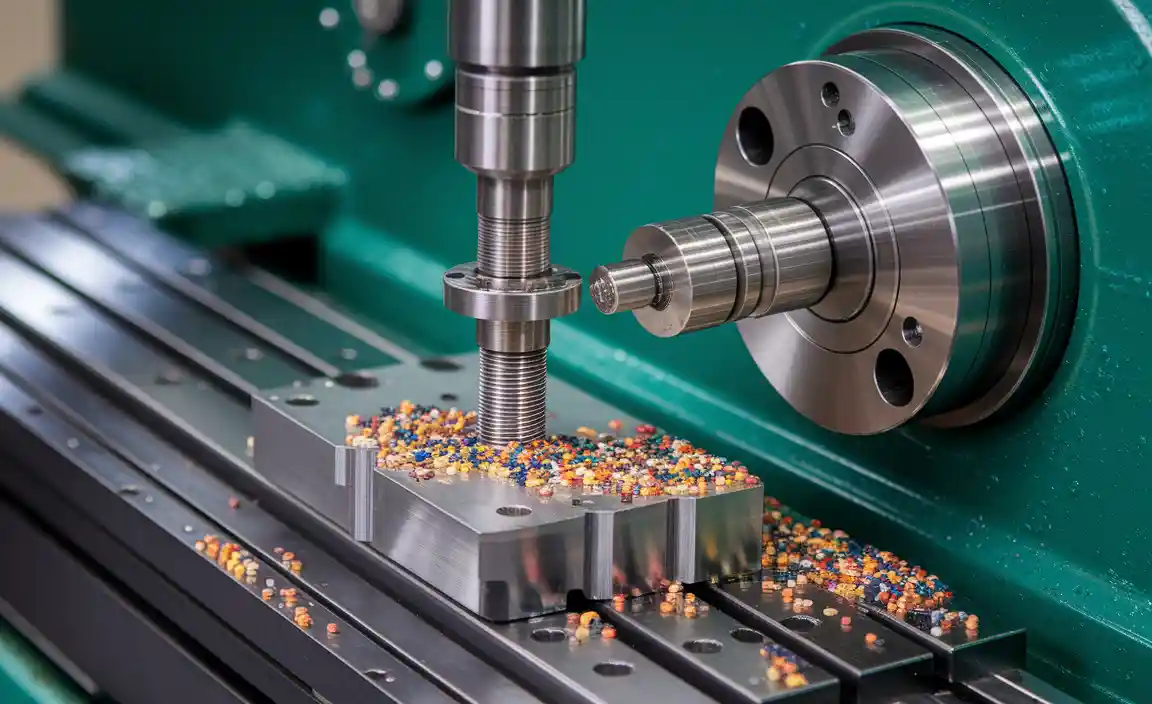

Mounting the Screw Chuck: Step-by-Step Guide

Detailed procedure for aligning and securing the screw chuck.. Common mistakes to avoid during the mounting process..

To mount the screw chuck, follow these steps:

- First, clean the lathe spindle.

- Align the screw chuck with the spindle carefully.

- Tighten the chuck securely without over-tightening.

- Double-check the alignment before starting the lathe.

Avoid these common mistakes:

- Skipping the cleaning step.

- Not ensuring proper alignment.

- Over-tightening, which can damage the chuck.

Being careful during these steps makes a big difference in your work.

What is the best way to secure a screw chuck?

Align the chuck carefully and tighten it firmly but not too much. This helps prevent accidents and ensures smooth operation.

Adjusting the Screw Chuck for Precision

Techniques for finetuning the chuck for accuracy.. Importance of balance and calibration in screw chuck usage..

To adjust your screw chuck for perfect accuracy, fine-tuning is key. Start by checking the alignment of the chuck. A misaligned chuck can cause problems. Balance is crucial too; an unbalanced chuck can lead to vibration and errors. Calibration helps ensure smooth operation. Regular checks keep your setup reliable. Here’s how to improve your adjustments:

- Ensure the chuck sits evenly on the lathe.

- Tighten screws gently and evenly.

- Use a dial indicator for precision measuring.

- Test the setup before use to confirm accuracy.

Why is calibration important?

Calibration is important because it makes sure your tools are working correctly. Small mistakes can lead to big problems in your work. Regular checks save time and material, keeping projects on track.

Maintenance and Troubleshooting Tips

Regular maintenance practices to prolong chuck life.. Common problems and their solutions related to screw chucks..

To keep your screw chuck working well, regular care is important. This helps it last longer. Here are some steps:

- Clean the chuck after each use.

- Check for wear on the threads.

- Lubricate moving parts regularly.

- Store in a dry place to avoid rust.

Sometimes, problems can happen with screw chucks. Here are common issues and ways to fix them:

- Chuck slips: Check tightness and clean jaws.

- Unusual noise: Inspect for dirt or damage.

- Wear and tear: Replace worn parts on time.

By following these tips, your screw chuck will stay strong and work better for longer!

Safety Precautions During Lathe Operation

Key safety tips to follow while using lathe machines with screw chucks.. Recommended personal protective equipment (PPE) to wear during operation..

Working with a lathe can be exciting, but safety comes first! Always wear protective goggles to shield your eyes from flying debris. Use ear protection to guard against loud noises. Keep your hair tied back and don’t wear loose clothing; we don’t want your shirt turning into a lathe stir-fry! It’s also smart to ensure your workspace is clean and organized. Here’s a quick look at essential PPE:

| Personal Protective Equipment (PPE) |

|---|

| Safety Goggles |

| Ear Protection |

| Gloves (if needed) |

| Hard Hat |

Remember, safety isn’t a choice; it’s a must! So, gear up and let’s turn that screw chuck safely!

Conclusion

In summary, we learned that mounting a screw chuck on a lathe involves careful steps. You start by selecting the right chuck and preparing your lathe. Then, you align and secure it properly. By following these steps, you can ensure safe and effective turning. To get hands-on experience, try it yourself or learn more from videos online!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Screw Chuck Mounting Steps:

Sure! When using a lathe, we need to mount the screw chuck. First, you put the screw chuck on the lathe. Next, you turn the handle to tighten it. Make sure it’s held tightly so it doesn’t move. Finally, test it by turning the lathe on slowly to ensure everything is secure.

Okay! I’m ready to help. Please go ahead and ask your question!

What Are The Essential Tools And Materials Needed For Mounting A Screw Chuck On A Lathe?

To mount a screw chuck on a lathe, you need a few tools. First, get a wrench to tighten the screws. You also need a screw chuck, which holds things while you work. Lastly, have some screws ready to attach the chuck securely. With these tools, you’re all set to start!

What Safety Precautions Should Be Taken Before Starting The Screw Chuck Mounting Process?

Before starting the screw chuck mounting, we should make sure the area is clean and tidy. Always wear safety glasses to protect your eyes. Check that your tools are in good shape and not broken. Keep your hands away from moving parts to avoid getting hurt. Finally, make sure you understand how to use the screw chuck safely.

How Do You Properly Align The Screw Chuck With The Lathe Spindle During Installation?

To align the screw chuck with the lathe spindle, you first clean both parts. Then, you carefully place the screw chuck on the spindle. Next, you tighten the screws slowly and check if everything fits well. Finally, spin the chuck by hand to make sure it moves smoothly. If it doesn’t, adjust it until it works perfectly.

What Are The Common Mistakes To Avoid When Mounting A Screw Chuck On A Lathe?

When you mount a screw chuck on a lathe, avoid a few big mistakes. First, make sure you tighten the screws well; otherwise, the chuck can come loose. Second, check that everything is clean and free of dirt. If the surfaces are dirty, the chuck won’t hold securely. Finally, always double-check that the chuck is centered properly; this helps your work be more accurate.

How Can You Ensure That The Screw Chuck Is Securely Fastened To Prevent Any Movement During Turning Operations?

To keep the screw chuck tight, you should check the screws. Make sure they are twisted on well. Use a wrench to tighten them if needed. After that, you can gently pull on the chuck to see if it moves. If it doesn’t move, you’re ready to start turning!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Turning Screw Chuck Mounting Steps:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a lathe, we need to mount the screw chuck. First, you put the screw chuck on the lathe. Next, you turn the handle to tighten it. Make sure it’s held tightly so it doesn’t move. Finally, test it by turning the lathe on slowly to ensure everything is secure.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Okay! I’m ready to help. Please go ahead and ask your question!”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Materials Needed For Mounting A Screw Chuck On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To mount a screw chuck on a lathe, you need a few tools. First, get a wrench to tighten the screws. You also need a screw chuck, which holds things while you work. Lastly, have some screws ready to attach the chuck securely. With these tools, you’re all set to start!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken Before Starting The Screw Chuck Mounting Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before starting the screw chuck mounting, we should make sure the area is clean and tidy. Always wear safety glasses to protect your eyes. Check that your tools are in good shape and not broken. Keep your hands away from moving parts to avoid getting hurt. Finally, make sure you understand how to use the screw chuck safely.”}},{“@type”: “Question”,”name”: “How Do You Properly Align The Screw Chuck With The Lathe Spindle During Installation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the screw chuck with the lathe spindle, you first clean both parts. Then, you carefully place the screw chuck on the spindle. Next, you tighten the screws slowly and check if everything fits well. Finally, spin the chuck by hand to make sure it moves smoothly. If it doesn’t, adjust it until it works perfectly.”}},{“@type”: “Question”,”name”: “What Are The Common Mistakes To Avoid When Mounting A Screw Chuck On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you mount a screw chuck on a lathe, avoid a few big mistakes. First, make sure you tighten the screws well; otherwise, the chuck can come loose. Second, check that everything is clean and free of dirt. If the surfaces are dirty, the chuck won’t hold securely. Finally, always double-check that the chuck is centered properly; this helps your work be more accurate.”}},{“@type”: “Question”,”name”: “How Can You Ensure That The Screw Chuck Is Securely Fastened To Prevent Any Movement During Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the screw chuck tight, you should check the screws. Make sure they are twisted on well. Use a wrench to tighten them if needed. After that, you can gently pull on the chuck to see if it moves. If it doesn’t move, you’re ready to start turning!”}}]}