Have you ever wondered how to create a beautiful pepper mill? Imagine having a unique piece in your kitchen that stands out. A lathe turning segmented pepper mill build can make that happen. It’s not just for experts; anyone can try it!

Many people enjoy woodworking as a hobby. But did you know that segmented turning can be even more fun? This technique lets you make eye-catching designs using different types of wood. Picture vibrant colors swirling together! It can surprise your guests as you serve delicious meals.

Building a lathe turning segmented pepper mill challenges your creativity. You can also learn new skills along the way. Plus, it makes your kitchen look great! Who wouldn’t want to impress friends and family with something handmade?

Ready to dive into this exciting project? Join us as we explore the steps to create your own amazing pepper mill. Let’s get started on this wonderful woodworking adventure!

Lathe Turning Segmented Pepper Mill Build: A Step-By-Step Guide

Understanding Lathe Turning

Explanation of lathe turning processes. Key tools and materials used in lathe turning.

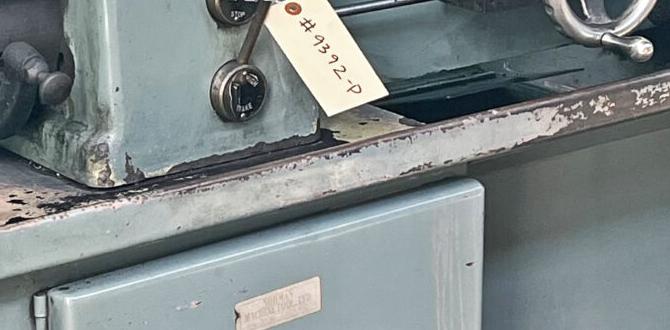

Lathe turning involves shaping materials into desired forms. A lathe spins the material, allowing tools to carve and cut. This method is great for making round objects.

Key tools and materials include:

- Lathe: The main machine used for turning.

- Cutting tools: Tools to shape the material, often made of steel.

- Workpiece: The material being shaped, like wood or plastic.

Using a lathe requires skill. Many makers enjoy creating unique items, like pepper mills, with this method. The process combines art and technology, making it fascinating.

What is the process of lathe turning?

The lathe turning process starts with securing the material onto the lathe. The machine spins it while the cutting tool shapes it. This method helps create smooth and precise designs.

Designing Your Segmented Pepper Mill

Importance of design planning and sketches. Choosing the right segment and shape configurations.

Before you dive into building your segmented pepper mill, make a plan. A good design sketch is like a treasure map; it guides your journey. Choose your segments wisely! Will they be round, square, or a mix? Think about shapes that dance together. Remember, the right configuration makes all the difference. A quirky design can make your mill a favorite conversation piece. Also, don’t forget – measuring twice can save you from making that *oops* moment!

| Design Aspect | Importance |

|---|---|

| Sketching | Guides the build process |

| Segment Choice | Affects the look and function |

| Shape Configuration | Creates a unique style |

Step-by-Step Building Process

Detailed steps from cutting segments to assembly. Tips for achieving precise cuts and fit.

Start by choosing sturdy wood for your pepper mill. Cut the wood into segments of equal sizes. Use a miter saw for precise angles. Ensure each segment fits well together. Sand the edges to smooth them out. Next, drill a hole in the center of each segment. This will help in fitting the mill’s mechanism. When assembling, glue the segments together tightly. Let them dry completely before use. Clean cuts and careful assembly make your mill look great!

What are the key steps in building a segmented pepper mill?

Key steps include cutting your wood, sanding the edges, drilling holes for the mechanism, and assembling the segments with glue.

Finishing Techniques for Your Pepper Mill

Various finishing options to enhance appearance and durability. Stepbystep process for applying finishes.

When it’s time to dress up your pepper mill, think about its finishing touches. You can choose from several finishes to make it shine and last longer. Common options include oil, wax, and lacquer. Each adds a unique look. Follow these simple steps: First, sand your mill to a smooth surface. Next, apply your finish of choice. Finally, buff it for a glossy shine. Remember, a well-finished pepper mill can spice up your kitchen more than a dancing chef!

| Finish Type | Appearance | Durability |

|---|---|---|

| Oil | Natural | Moderate |

| Wax | Soft glow | Good |

| Lacquer | High gloss | Excellent |

Testing and Adjustments

Importance of testing the functionality of the pepper mill. Common adjustments to improve performance.

Testing the pepper mill is key to making sure it works well. You want to check the grind size and ease of use. Adjustments may be needed for better performance. Here are some common changes:

- Change the grind setting if it’s too coarse or too fine.

- Tighten or loosen parts that may be loose.

- Clean the grinding mechanism to avoid clogs.

Regular testing helps ensure the mill grinds smoothly and lasts longer. Enjoy the perfect sprinkle of fresh pepper on your meals!

What are some signs your pepper mill needs adjustment?

If your mill is hard to turn or doesn’t grind well, it may need adjustment. Checking the grind size and cleaning it can help improve its performance.

Maintenance Tips for Longevity

Recommended care and maintenance practices. How to troubleshoot common issues with segmented pepper mills.

To keep your pepper mill in top shape and avoid salty situations, regular care is essential. First, clean it often. Remove any stuck pepper bits to avoid clogs. Use a soft cloth and mild soap. Don’t soak the wood; it’ll get cranky! If your mill gets squeaky, try a drop of food-safe mineral oil. Trouble with grinding? Ensure the burrs are aligned. If the pepper still won’t come out, check for blockages.

| Issue | Solution |

|---|---|

| Squeaky mill | Apply food-safe mineral oil |

| Pepper won’t grind | Check for clogs |

| Pepper spills | Adjust the grind setting |

Keeping your segmented pepper mill happy will spice up your cooking. After all, no one wants bland food or a cranky kitchen tool!

Conclusion

In summary, building a lathe-turned segmented pepper mill is a fun project! You get to create something unique while learning new skills. Remember to plan your design and choose good wood. As you work, be patient and careful. Try it out yourself, and don’t hesitate to explore more tutorials online for inspiration. Happy woodworking!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Building A Segmented Pepper Mill Using A Lathe:

Sure! Here are five questions about making a segmented pepper mill with a lathe: 1. What tools do you need to make a pepper mill? 2. How do you choose wood for your pepper mill? 3. What designs can you use for the segments? 4. How do you put the pieces together? 5. How do you make sure the mill grinds well? Let me know if you want more information on any of these!

Sure! Please provide the question you would like me to answer.

What Types Of Wood Are Best Suited For Creating A Segmented Pepper Mill, And How Do The Properties Of Each Type Affect The Final Product?

Good woods for a segmented pepper mill are maple, walnut, and cherry. Maple is hard and smooth, making it last a long time. Walnut is dark and beautiful, which makes the pepper mill look nice. Cherry is also pretty and gets prettier with time. Each wood gives the mill a different look and feel!

What Is The Process For Designing And Calculating The Segments Needed For A Segmented Pepper Mill, And What Tools Can Assist In This Process?

To design a segmented pepper mill, you first decide how many pieces you want. Each segment will hold pepper and spin to grind it. You can use a ruler to measure and a pencil to draw your shapes. Next, you might want to use a computer program to help you see what it will look like. Finally, you can cut the pieces carefully and put them together.

How Do You Ensure Proper Alignment And Glue-Up Of The Segments During The Construction Of A Segmented Pepper Mill?

To keep the pieces of your pepper mill lined up, you can use rubber bands or clamps. First, apply glue to the edges of each segment. Then, press them together carefully and check that they are straight. Make sure to let the glue dry completely before you finish the mill. This way, your pepper mill will look great and work well!

What Techniques Can Be Used For Shaping And Finishing The Exterior Of A Segmented Pepper Mill On The Lathe To Achieve A Professional Look?

To shape your segmented pepper mill, start by using a lathe to carefully turn the wood. You can use different chisels to smooth out the corners and make it round. After shaping, sand the surface with fine sandpaper to make it feel nice and smooth. Finally, you can apply a coat of finish, like oil or wax, to protect the wood and make it shiny. This will give your pepper mill a beautiful and professional look!

What Are The Common Challenges Faced During The Turning And Assembly Of A Segmented Pepper Mill, And How Can They Be Overcome?

When making a segmented pepper mill, we often face a few problems. First, pieces can slide or not fit together well. To fix this, we can use glue carefully and check the fit before it dries. Second, it can be hard to turn the pieces evenly. You can use special tools to help keep everything balanced. Finally, the assembly can be tricky, but taking your time and following steps helps a lot!