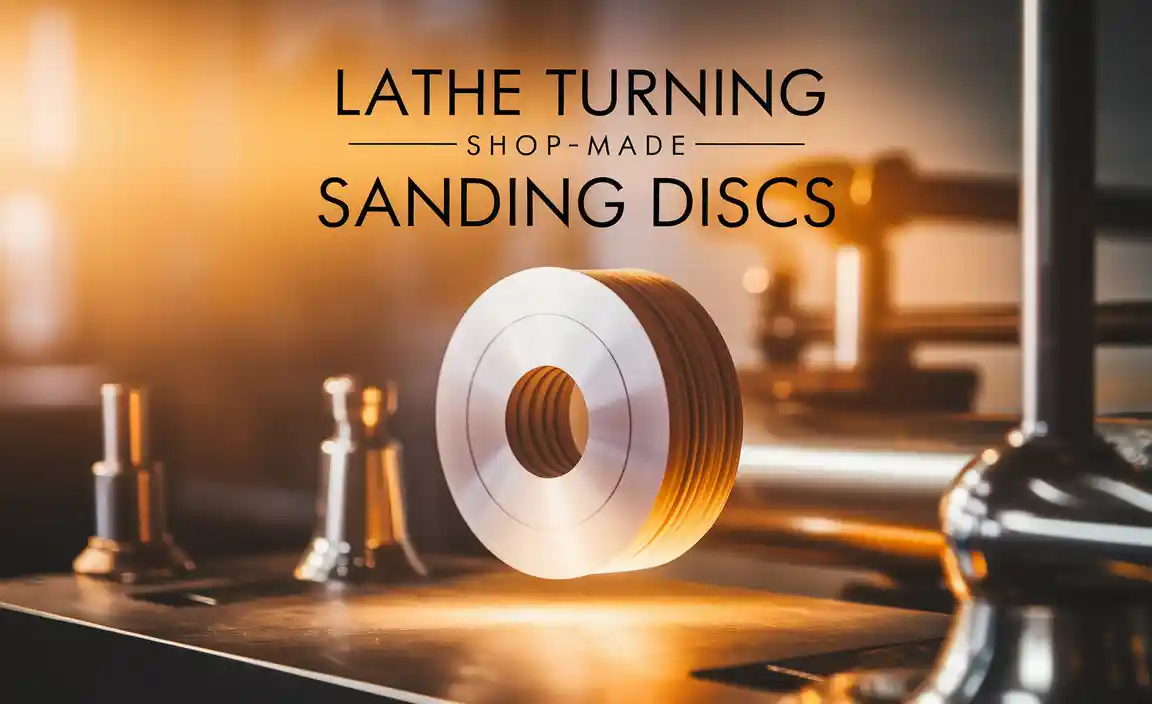

Have you ever watched a lathe in action? It’s fascinating! A lathe spins materials to shape them into precise items. But did you know that adjusting the turning speed by diameter is really important? The right speed makes all the difference in how well the piece turns out.

Imagine you’re crafting a beautiful wooden bowl. If the speed is too fast, you might end up with splinters. Too slow, and it will take forever to finish. Getting that balance can feel tricky. But don’t worry! By understanding lathe turning speed adjustment, you can master the craft.

Here’s a fun fact: did you know that the diameter of the material directly affects the speed you should use? It’s true! Bigger pieces need slower speeds, while smaller ones can handle faster spins. Curious about how to make these adjustments? Let’s dive into the world of lathe turning and find out!

Lathe Turning Speed Adjustment By Diameter: A Guide

Lathe Turning Speed Adjustment by Diameter

Lathe turning speed adjustment is crucial for your projects. Did you know that the diameter of the workpiece affects the speed? When the diameter increases, you need to lower the speed. This keeps the cuts clean and safe. For example, large logs need slower speeds to avoid splintering. Adjusting the lathe speed not only improves your work but also extends the life of your tools. Remember, right speed means better results!Understanding Lathe Turning Speed

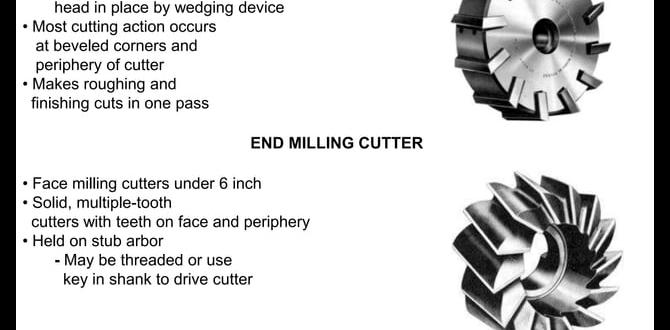

Definition of lathe turning speed. Importance of speed for machining efficiency and tool life.Lathe turning speed is how fast the lathe spins the material you’re working on. This speed is super important for keeping both the machining efficient and the tools happy. If it’s too fast, it can wear out tools quickly—a bit like how too much candy can ruin your teeth! Knowing the right speed helps you create smooth finishes while extending tool life. So, remember: speed matters!

| Diameter (inches) | Recommended Speed (RPM) |

|---|---|

| 1 | 1800 |

| 2 | 900 |

| 3 | 600 |

Factors Influencing Lathe Speed Adjustment

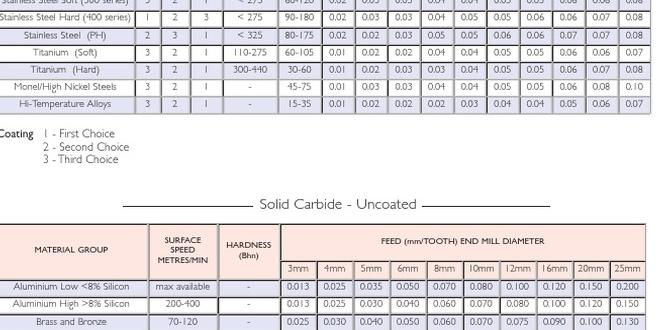

Material composition of the workpiece. Diameter of the workpiece and its impact on speed. Tool type and geometry considerations.Many things affect how fast you should turn a lathe. First, the material composition of the workpiece matters. Different materials, like metal or wood, require different speeds. Next, the diameter of the workpiece impacts the speed. A larger diameter needs a slower speed to cut safely. Lastly, the tool type and geometry affect speed too. Sharp tools work better at higher speeds, while dull ones need slower speeds.

What materials work best with different lathe speeds?

Materials like steel and aluminum often need faster speeds, while wood and plastic work well at slower speeds.

Factors to Consider:

- Material type

- Size of the workpiece

- Sharpness of the tool

Calculating Optimal Speed Based on Diameter

Formula for determining RPM (Revolutions Per Minute). Example calculations for various diameters.Finding the best speed for your lathe is key to making smooth cuts. You can calculate the optimal RPM using this simple formula:

RPM = (Diameter x 3.82)

Let’s look at some examples:

- 1-inch diameter: RPM = 3.82

- 2-inch diameter: RPM = 7.64

- 3-inch diameter: RPM = 11.46

This method helps you find the right speed faster. Always adjust your RPM based on the size of your workpiece. Happy turning!

How do you calculate the RPM for lathe turning?

You can calculate the RPM for lathe turning by using the formula RPM = (Diameter x 3.82). This will ensure you choose the best turning speed suitable for each diameter.

Guidelines for Speed Adjustment

Recommended speeds for different materials (e.g., metals, plastics). Adjusting speed based on tool wear and finish requirements.Choosing the right speed for lathe turning helps you get the best results. Every material needs a different speed. Here are some examples:

- Metal: 500-1200 RPM is good for turning aluminum and steel.

- Plastic: 1000-3000 RPM works well for most plastics.

Adjusting speed is also important based on two things:

- Tool wear: If your tool is worn out, slow down the speed to be safe.

- Finish requirements: If you need a smooth finish, use a slower speed.

Remember, taking the time to adjust properly can save you from mistakes.

What speed should I use for different materials?

For metals, like aluminum and steel, **500-1200 RPM** is ideal. For plastics, **1000-3000 RPM** is better. Each material needs the right speed for the best results.

Common Mistakes in Speed Adjustment

Overspeeding and its consequences. Underspeeding and impact on machining quality.Many people make mistakes when adjusting their lathe speed. Overspeeding can lead to catastrophic failures. You might think you’re a speed demon, but accidents happen when things spin too fast! Parts could break or fly off, which is not fun. On the flip side, underspeeding can be just as bad. It might create rough surfaces, meaning more sanding later. Remember, if your machining looks like a potato, you’re probably going too slow!

| Speed Adjustment Mistake | Consequence |

|---|---|

| Overspeeding | Breakage and accidents |

| Underspeeding | Poor surface finish |

Advanced Techniques for Speed Adjustment

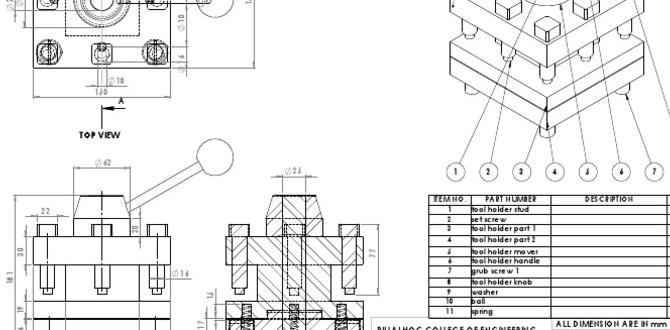

Utilizing digital readouts and automated controls. Incorporating feedback loops for precision machining.Speed adjustment can feel like a magic trick, especially with digital readouts and automated controls. These tools make changing speeds smoother than a ninja in slippers! By using feedback loops, machines can learn from their performance. This helps achieve fine-tuned precision that even a watchmaker would envy. You’ll never have to guess again, and your lathe will work like a dream!

| Technique | Benefits |

|---|---|

| Digital Readouts | Easy speed tracking |

| Automated Controls | Quick adjustments |

| Feedback Loops | Enhanced accuracy |

With these advanced techniques, your lathe will spin like a champion at a pie-eating contest!

Safety Considerations in Speed Adjustment

Importance of personal protective equipment (PPE). Tips for safe operation while adjusting lathe speed.Before playing with lathe speeds, make sure you wear your personal protective equipment (PPE). This means goggles for your eyes, gloves for your hands, and ear protection to save your hearing. Safety first, right? Always check the machine and tools before making any adjustments. Never operate the lathe if you’re feeling sleepy. That’s like trying to ride a bike with your eyes closed!

| Item | Importance |

|---|---|

| Goggles | Protects eyes from flying chips |

| Gloves | Prevents cuts and scrapes |

| Ear Protection | Stops noise from causing damage |

Remember, taking safety precautions can help you enjoy your lathe work without a hitch and keeps your fingers right where they belong—attached to your hands! Stay smart, stay safe, and happy turning!

Best Practices for Maintenance Related to Speed Adjustment

Regular checks on lathe mechanics for optimal performance. Importance of lubricants and cooling fluids in speed management.To keep your lathe working like a charm, check its parts regularly. It’s like feeding your pet; if you don’t, they get cranky! Lubricants and cooling fluids are your best friends here. They keep everything running smoothly and help manage speed. Without them, things can get a bit too hot to handle. Remember, a happy lathe is a well-maintained lathe!

| Maintenance Tip | Benefit |

|---|---|

| Regular Checks | Optimal performance |

| Use Lubricants | Smoother operation |

| Apply Cooling Fluids | Speed management |

Conclusion

In summary, lathe turning speed adjustments depend on the diameter of the material. Larger diameters require slower speeds, while smaller ones can turn faster. This helps create smoother finishes and better accuracy. Remember to measure carefully and adjust your speed accordingly. To learn more, explore guides on lathe operation or practice adjusting speeds on different projects. Happy turning!FAQs

What Is The Formula For Calculating The Optimal Lathe Turning Speed Based On The Diameter Of The Workpiece?To find the best turning speed for a lathe, you can use this formula: Speed (in RPM) = (Diameter (in inches) × 100)/3.14. First, you measure the diameter of your workpiece in inches. Then, you multiply that number by 100. Finally, divide by 3.14, which is like the number Pi. This gives you the speed in revolutions per minute (RPM) you should use for turning.

How Does The Material Of The Workpiece Influence The Lathe Turning Speed For Different Diameters?The material of the workpiece changes how fast we can turn it on a lathe. Softer materials, like plastic, can spin faster than harder ones, like steel. If the piece is big, we may need to slow down. This helps us cut smoothly without breaking anything. So, the type of material and size both matter for speed.

What Are The Consequences Of Using An Incorrect Turning Speed When Machining A Large Versus A Small Diameter Component?Using the wrong turning speed when machining can cause problems. For big parts, if you turn too fast, it can break or warp. For small parts, a slow speed might make them look rough or uneven. It’s important to pick the right speed, so we get the best results and keep parts safe.

How Can A Machinist Adjust The Lathe Turning Speed For Varying Diameters During A Production Run?To adjust the lathe turning speed for different sizes of parts, you need to change the speed setting. If the part is bigger, you should lower the speed. For smaller parts, increase the speed. This helps you cut the material smoothly and safely. Always check the machine’s manual for the best speeds!

What Factors Should Be Considered When Determining The Maximum Allowable Turning Speed For A Workpiece Of A Specific Diameter?When deciding how fast to turn a workpiece, we need to think about a few things. First, consider the size of the workpiece. Larger pieces can’t spin as fast without breaking. Next, think about the material. Hard materials might need slower speeds to avoid damage. Lastly, keep safety in mind. If it’s too fast, it can be dangerous.