Have you ever wondered how parts are made in factories? It’s a fascinating process! One key tool in this process is a lathe. This machine shapes materials into precise forms. But did you know that the right spindle size can make all the difference?

The lathe turning spindle size gauge is essential for getting it right. It helps you measure the spindle accurately. But why does it matter? A small mistake can lead to big problems in manufacturing.

Imagine trying to fit a square peg in a round hole. Frustrating, right? That’s what it’s like without the right spindle size. Understanding how to use a lathe turning spindle size gauge can save time and effort.

In this article, we’ll explore why these gauges are important. We’ll share tips on choosing the right one. Get ready to learn how small tools can make a big difference!

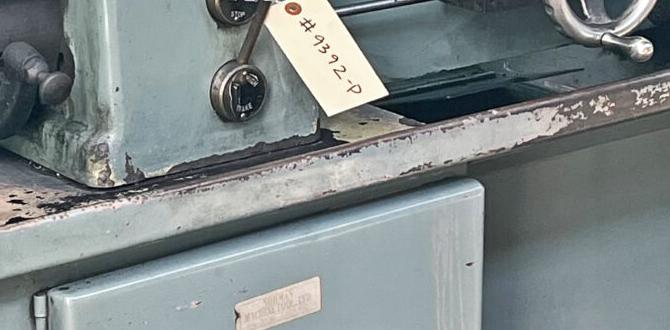

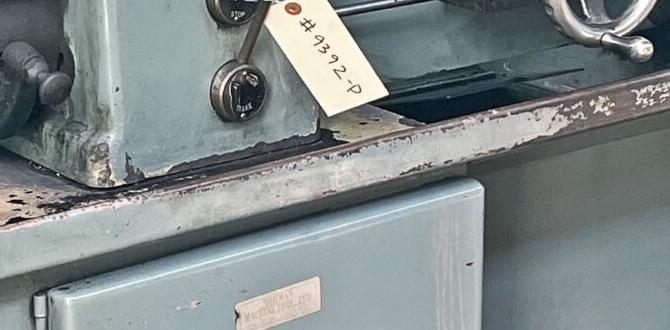

Lathe Turning Spindle Size Gauge: Essential Measurement Tool

Understanding Lathe Turning Spindle Size Gauge

A lathe turning spindle size gauge helps ensure your lathe works well. Why does size matter? The right spindle size lets you create smooth and precise shapes. Using an incorrect gauge can lead to mistakes in your projects. Did you know that choosing the wrong size might even damage your machine? Properly measuring spindle size can make your woodworking smoother and more enjoyable. Always check your lathe’s specifications before starting!What is a Lathe Turning Spindle Size Gauge?

Definition and purpose of the spindle size gauge. Importance in machining and lathe operations.A lathe turning spindle size gauge is a handy tool. It helps measure the size of spindle holes. Think of it as a ruler but for spindles! By using this gauge, machinists can ensure that the parts fit just right. This is super important in machining. When parts fit well, machines run smoothly. Who wants their machine sputtering like a cat with a hairball? Not us! Proper measurements save time and reduce waste. They help professionals make precise and quality parts.

| Function | Importance |

|---|---|

| Measures spindle sizes | Ensures proper fit |

| Enhances accuracy | Reduces mistakes |

| Speeds up production | Improves efficiency |

How to Choose the Right Spindle Size Gauge

Factors to consider (e.g., accuracy, material, brand). Common mistakes to avoid when selecting a gauge.Choosing the right size for a spindle gauge matters a lot. First, consider accuracy. You want a gauge that gives you exact measurements. Next, look at the material. Good quality materials make a sturdy gauge. Don’t forget to check the brand. Trusted brands often ensure reliability. Beware of common mistakes too. Many overlook usage instructions or choose the wrong size, leading to errors. Always double-check these factors before buying!

What mistakes should I avoid when selecting a spindle size gauge?

Avoid these pitfalls:

- Not checking for accuracy.

- Ignoring material quality.

- Picking the wrong size.

- Overlooking brand reputation.

How to Use a Lathe Turning Spindle Size Gauge

Stepbystep instructions on proper usage. Tips for achieving accurate measurements.Using a lathe turning spindle size gauge can be easy and fun! First, make sure your lathe is off. Measure the spindle diameter with your gauge. Insert the gauge gently into the spindle. If it fits snugly, you’re on the right track. If it doesn’t, try a larger size. Accurate measurements matter! It’s like trying to fit into your favorite jeans after Thanksgiving. You want them to fit, but not too tight! Remember to double-check by measuring again for the best results. Finally, record your measurements for future use.

| Step | Action |

|---|---|

| 1 | Turn off the lathe. |

| 2 | Insert the gauge into the spindle. |

| 3 | Check for a snug fit. |

| 4 | Double-check your measurement. |

| 5 | Record your findings. |

Maintenance and Care for Spindle Size Gauges

Best practices for cleaning and storing gauges. Signs of wear and when to replace.Keeping your spindle size gauge in great shape is crucial. Always clean your gauges after use. Use a soft cloth and mild cleaner. Store them in a dry place, away from dust. Check for signs of wear like scratches or chips. If you see any, it might be time to replace them. Proper care helps your tools last longer!

What are the best practices for cleaning and storing spindle size gauges?

Cleaning and storing properly will keep your gauges accurate. Always wipe them down after use. Store them in a protective case to avoid dust or damage. Make sure your storage area is dry.

Signs of Wear and Replacement

- Visible scratches or chips

- Difficulty in measurement

- Rust or corrosion

If you notice these signs, consider replacing your gauge. A reliable tool ensures a great finish on your projects.

Common Issues and Troubleshooting

Typical problems encountered during use. Solutions and preventive measures.Using a lathe can feel like a dance with precision, but sometimes you trip over your own feet! Common problems include vibrations and incorrect spindle sizing. Vibrations can make your work look like it has a bad hair day. To fix this, check if everything is tightened properly—imagine your lathe in a snug sweater! For sizing, always measure twice and cut once; a little extra planning helps. Remember, prevention is key!

| Issue | Solution | Prevention |

|---|---|---|

| Vibrations | Tighten all loose parts | Regular maintenance |

| Incorrect spindle size | Measure your components | Double-check sizes |

Applications of Lathe Turning Spindle Size Gauges in Industry

Key industries that utilize these gauges. Case studies showcasing practical applications.Many industries rely on lathe turning spindle size gauges for their precision needs. Manufacturing is a primary sector using these gauges to create parts that fit perfectly. For example, the automotive industry uses them to ensure that a tiny screw fits just right. Case studies show that using these gauges can reduce errors and save money. In a recent project, a company improved its output by 20%! Here’s a quick look at some key industries:

| Industry | Application |

|---|---|

| Automotive | Precision parts manufacturing |

| Aerospace | Safety-critical component fitting |

| Medical | Exact measurement for devices |

Measurements matter! Without accurate gauges, parts could go haywire—like a cowboy at a square dance! Let’s celebrate precision! 🎉

Comparing Spindle Size Gauges to Other Measurement Tools

How spindle size gauges stack up against calipers and micrometers. When to use each type of measurement tool.Choosing the right tool for measuring spindle sizes can feel like a maze. Spindle size gauges are like the trusty sidekick, perfect for quick checks. They fit right into the spindle, making them spot on for turning tasks. On the other hand, calipers and micrometers are like the superheroes of precision—they measure everything, even that last piece of cake! They’re best for detailed work and can be handy when you want to impress your friends with your measuring skills.

| Tool | Best For |

|---|---|

| Spindle Size Gauge | Quick spindle checks |

| Calipers | General measurements |

| Micrometers | Extreme precision |

Future Trends in Lathe Turning Measurement Technology

Innovations in gauge technology. Predictions for the future of lathe turning measurement tools.New tools for measuring lathe turning sizes are popping up like popcorn at a movie! Innovations in gauge technology promise to make measurements quicker and more accurate. Check out these cool trends:

| Innovation | Description |

|---|---|

| Smart Gauges | Devices that connect to apps for instant feedback! |

| Laser Measurements | Using lasers for precision? Now that’s sci-fi! |

By 2030, we might see **fully automated measurement systems** that do the job while we sip coffee. Imagine a future where you can measure while dancing the cha-cha! Hold onto your hats—lathe turning technology is only getting more exciting!

Conclusion

In summary, a lathe turning spindle size gauge helps you measure spindle sizes accurately. Knowing the right size improves your projects and tool choices. Use this gauge to ensure your workpieces fit properly. If you’re interested, explore more about lathe tools and techniques. By learning more, you can enhance your skills and create amazing projects. Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Turning Spindle Size Gauges:Sure! Lathe turning spindle size gauges help us measure the size of spindle parts when we work with a lathe. A lathe is a machine that shapes materials like wood or metal. We use these gauges to make sure everything fits together perfectly. They help us create smooth and precise shapes. This way, our projects come out looking great!

Sure! Please provide the question you want me to answer.

What Are The Common Types Of Spindle Size Gauges Used In Lathe Turning, And How Do They Differ In Application?Common types of spindle size gauges for lathe turning include calipers and bore gauges. Calipers measure the outside and inside sizes of objects. Bore gauges check the size of holes. They differ because calipers are good for surface measuring, while bore gauges are best for checking inside spaces. Each tool helps make sure we get the right sizes for our projects.

How Do You Accurately Measure The Spindle Size On A Lathe Using A Gauge, And What Are The Best Practices To Ensure Precision?To measure the spindle size on a lathe, you can use a gauge. First, make sure the gauge touches the spindle lightly. Then, read the measurement on the gauge carefully. For best results, check the measurement at different points around the spindle. Always keep the gauge clean and handle it carefully to avoid mistakes.

What Are The Consequences Of Using Incorrect Spindle Size Gauges In Lathe Turning Operations?Using the wrong spindle size gauge can cause big problems. First, your workpiece might not fit on the lathe properly. This can create wobbly pieces that are hard to shape. Second, it can cause damage to the lathe itself, making it not work right. Lastly, you could waste materials and time trying to fix mistakes.

Can You Explain The Relationship Between Spindle Size And The Types Of Materials That Can Be Effectively Turned On A Lathe?The spindle size of a lathe is how big the part that holds the material is. A larger spindle can hold bigger pieces of wood or metal. This means you can work on larger projects with it. Smaller spindles are better for smaller pieces. So, the size helps us know what materials we can use.

What Factors Should Be Considered When Selecting A Spindle Size Gauge For Specific Lathe Projects?When picking a spindle size gauge for your lathe projects, think about a few things. First, consider the size of the pieces you’ll work on. You want a gauge that fits well. Second, check the weight of your projects. A heavier project needs a sturdier gauge. Lastly, make sure the gauge is easy for you to use and read.