Have you ever noticed rough edges on a shiny piece of metal? Those are called burrs. Burrs can make your work look messy and feel rough. But don’t worry! There is a great method to remove those annoying burrs using a lathe turning tool.

Imagine you just finished a project, and it looks fantastic. You want to show it off, but those pesky burrs ruin everything. What if there was a way to fix that quickly? The lathe turning tool burr removal method can help you achieve a smooth finish without a lot of fuss.

Did you know that even expert machinists sometimes struggle with burrs? It’s true! Removing them efficiently can save time and make your projects stand out. With the right approach, you can smooth out those edges and create something beautiful.

Join us as we explore tips and tricks for using the lathe turning tool burr removal method. Your next project will shine like never before!

Effective Lathe Turning Tool Burr Removal Methods You Need

Lathe Turning Tool Burr Removal Method

Burrs on lathe projects can ruin your work. Learning how to remove these small, sharp edges is important for a smooth finish. One effective method involves using specialized tools for precise cleaning. You can also use sandpaper for finer jobs. Did you know that burrs can affect the strength of your piece? Keeping your lathe tools clean leads to better results in your projects. Try these techniques to improve your lathe skills and create flawless pieces.Understanding Burr Formation in Lathe Turning

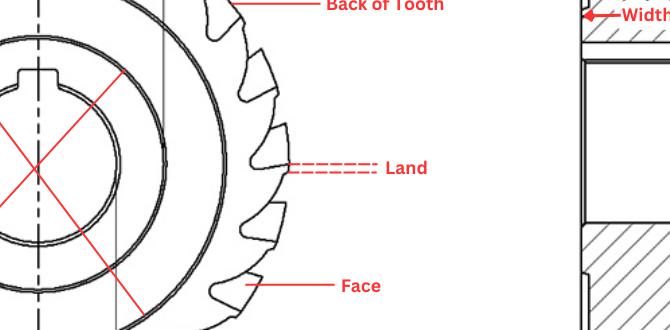

Definition of burrs and their types. Common causes of burr formation during lathe turning.Burrs are tiny scraps of material that cling to cut edges after shaping. They can be annoying, much like that last piece of cereal that always gets stuck in the bowl! There are several types of burrs, including mechanical and thermal, each formed by different methods during lathe turning. Common causes of these pesky burrs often include excessive pressure, dull tools, and poor setup. Just like a chef needs sharp knives for perfect slices, lathe operators need sharp tools to avoid those unwanted shavings!

| Type of Burr | Description |

|---|---|

| Mechanical Burrs | Formed from cutting action and tool pressure. |

| Thermal Burrs | Created due to heat during the cutting process. |

Importance of Burr Removal in Machining

Impact of burrs on product quality and finish. Safety considerations related to burrs in machining.Burrs are tiny bits of metal left on products after machining. They can make the surface look rough and hurt the overall quality. Removing burrs helps improve the finish. It can make products safer too. Burrs can cause cuts or injuries. Here are some important points to consider:

- They can affect product performance.

- Burrs can slow down machinery.

- They can cause accidents.

Overall, taking the time to remove burrs is very important for safety and quality.

Why is burr removal important?

Burr removal is crucial for ensuring high-quality products and safe work environments. It enhances appearance and prevents accidents during use.

Key Reasons:

- Improves aesthetic appeal.

- Reduces risk of injury.

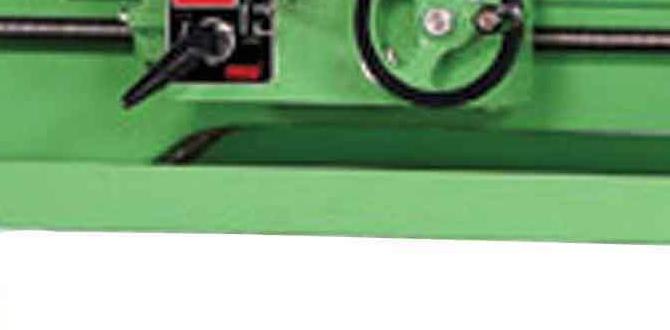

Step-by-Step Burr Removal Process Using Lathe Turning Tools

Preparation and setup for burr removal. Detailed steps for applying different removal methods.To remove burrs effectively, start by preparing your workspace. Ensure it is clean and organized. Gather your tools and safety gear like goggles and gloves. Follow these steps:

- Choose the right lathe turning tool for your project.

- Set your tool at the correct speed for the material.

- Apply light pressure when cutting to avoid damage.

- Use smooth, even strokes to create a clean cut.

- Inspect the work regularly for remaining burrs.

This method helps keep your project neat and safe!

What is the best method for burr removal?

The best method for burr removal is to use a lathe turning tool at a slow speed. This reduces the chance of creating more burrs. Always check your work often to catch any issues before they grow larger.

Best Practices for Preventing Burr Formation

Tips for tool selection and maintenance. Techniques to optimize machining parameters.Preventing burrs can save time and keep your projects smooth. Choosing the right tool is key. Use sharp tools—they are like the superheroes of machining! A dull tool can create burrs faster than a speeding bullet. Regular maintenance of your tools keeps them in top shape. Also, let’s not forget about the settings. Adjusting speed and feed rates can help. Find the perfect balance for your material.

| Tip | Explanation |

|---|---|

| Use Sharp Tools | Sharp tools create clean cuts and reduce burrs. |

| Regular Maintenance | Keep tools clean to ensure they work well. |

| Optimize Settings | Adjust speed and feed for better results. |

Knowing how to set up your lathe properly can be as crucial as knowing how to handle a pizza cutter—no one wants a messy slice! Small adjustments lead to big changes, making your project burr-free and nice to touch.

Case Studies: Successful Burr Removal in Various Industries

Examples from automotive and aerospace sectors. Lessons learned and best practices from each case.In the automotive sector, companies learned that using precise lathe turning tools prevents pesky burrs. One case study showed a 25% reduction in production time! In aerospace, removing burrs means safer flights. A well-known manufacturer found that their burr removal method cut rework costs by 30%. They both discovered that proper training and tools are key. Good practices equal fewer headaches!

| Industry | Success Highlights | Lessons Learned |

|---|---|---|

| Automotive | 25% faster production | Train staff well! |

| Aerospace | 30% lower rework costs | Right tools, right results! |

Future Trends in Burr Removal Technology

Innovations and emerging technologies in the field. Predictions for the future of burr removal methods.The world of burr removal is spinning like a lathe! Exciting new tools are popping up, ready to make the process faster and easier. Some might even look like magic wands! Did you know that robotic systems could one day do this work? They’ll zap away burrs in the blink of an eye, leaving your workpiece as smooth as a baby’s cheek. Imagine saying goodbye to manual labor!

| Future Innovations | Description |

|---|---|

| Robotic Burr Removal | Machines that remove burrs automatically—like a robot chef! |

| Smart Tools | Tools that learn to adjust themselves for the best finish. |

Predictions say that these cool gadgets will save time and effort. Who wouldn’t want to work less and laugh more? So, keep an eye on this space—burr removal is turning into a fun tech show!

FAQs About Lathe Turning Tool Burr Removal

Common questions and expert answers about burr removal. Clarifications on misconceptions in burr management.Many people have questions about removing burrs from lathe tools. Here are some common ones:

What are burrs?

Burrs are tiny, rough edges left on metal after cutting. They can affect the smoothness of your work.

How do I remove burrs?

You can use abrasive pads or files to smooth out the edges. Be sure to do this carefully for the best results.

Can I prevent burrs?

Yes! Using the right tools and settings can help reduce burr formation while you work.

Do burrs affect tool performance?

Yes, burrs can lead to poor cuts and damage tools over time. Keeping them in check is important.

By understanding these points, you can manage burrs effectively and improve your lathe projects!

Conclusion

In summary, removing burrs from lathe turned pieces is crucial for quality. You can use methods like sanding, grinding, or a deburring tool. Each method has its benefits, so choose one that fits your project. Experiment with these techniques, and you’ll see great results. For more tips, consider reading about specific tools for lathe work!FAQs

What Are The Most Effective Techniques For Removing Burrs From Lathe-Turned Pieces Without Damaging The Surface Finish?To remove burrs from lathe-turned pieces, we can use a few safe techniques. First, you can gently use sandpaper. Choose a fine-grit type so it doesn’t scratch the surface. Second, a soft file can help smooth out the burrs without hurting the finish. Lastly, a soft cloth with a little oil can polish the piece and remove tiny burrs easily.

How Does The Choice Of Tool Material Affect Burr Formation During Lathe Turning, And What Can Be Done To Minimize Burrs?The material of the cutting tool can change how burrs form. Harder tools usually make cleaner cuts, which means fewer burrs. To reduce burrs, you can use sharp tools and adjust the cutting speed. Plus, keeping the tool cool can help too. By doing these things, we can make smoother parts with less mess!

What Are The Advantages And Disadvantages Of Using Manual Vs. Automated Methods For Burr Removal In Lathe Turning Operations?Using manual methods for burr removal lets you feel and see what you’re doing. You can be very detailed and careful. However, it can take a lot of time, which might slow you down. Automated methods can be faster and save you time since machines do the work. But they can sometimes miss small burrs and cost more to set up.

Are There Specific Types Of Brushes Or Abrasives That Are Recommended For Deburring Lathe-Turned Components?Yes, there are special brushes and abrasives for cleaning lathe-turned parts. You can use nylon brushes to remove small bumps. For tough spots, try using fine sandpaper. These help make the metal smooth and safe to touch. Always wear safety goggles when you clean!

How Can The Design Of A Lathe Turning Process Be Optimized To Reduce The Incidence Of Burrs And Simplify The Subsequent Removal Process?To reduce burrs on a lathe, you can change how you cut the material. Use sharper tools, as they make cleaner cuts. You can also adjust the speed and pressure when cutting, which helps. Lastly, design parts with smooth edges to make burrs easier to remove later. This way, we keep things tidy and save time!