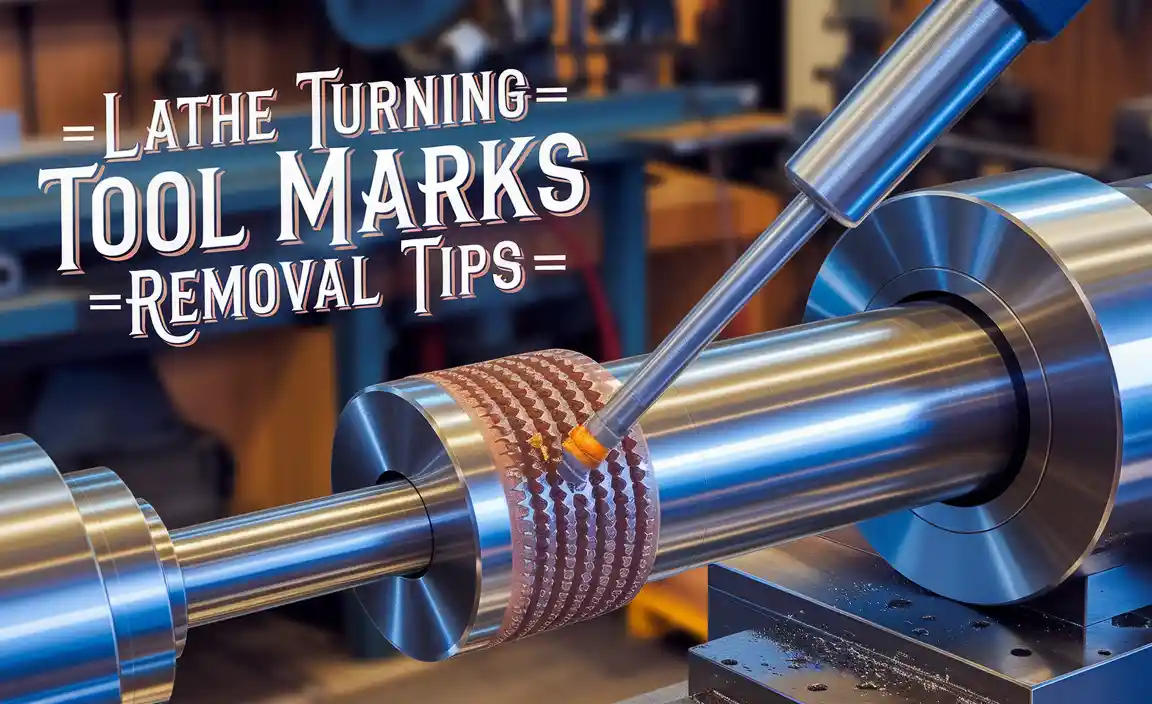

Have you ever picked up a piece of wood and noticed those annoying lathe turning tool marks? They can really spoil a nice project, right? But guess what? You don’t have to live with them!

Imagine crafting a beautiful table or a wooden bowl. You spend hours shaping it, only to see those pesky marks at the end. It’s frustrating! But there’s good news. Removing those tool marks is easier than you think.

In this article, we will share helpful tips on how to remove lathe turning tool marks. You’ll learn simple methods and techniques that anyone can try. Whether you’re a beginner or a seasoned pro, you’ll find something useful.

Are you curious about the best tools and tricks to make your projects shine? Stay with us, and let’s dive into the world of smoother finishes together!

Lathe Turning Tool Marks Removal Tips For A Smooth Finish

Understanding Tool Marks on Wood and Metal

Definition of tool marks and their causes. Difference between wood and metal tool marks.

Tool marks are small grooves or scratches left on a surface after cutting or shaping material. They can be caused by tools that are too rough or not used correctly. On wood, tool marks can show as fibers being pulled or uneven surfaces. For metal, they often appear as scratches or dents.

- Wood Tool Marks: Usually softer, and can be smoothed easily.

- Metal Tool Marks: Tend to be sharper and more visible, making removal more challenging.

Knowing the differences between these marks helps choose the right removal method.

What causes tool marks?

Tool marks happen mainly due to the tool’s condition or the wrong technique. Using a dull tool can lead to more visible marks on both wood and metal.

Importance of Proper Tool Selection

Types of lathe tools and their impact on surface finish. Selecting the right tool for specific materials.

Choosing the right lathe tool is like picking the best slice of pizza – you want it to be perfect! Each type of tool can change the smoothness of your workpiece. For example, a sharp HSS tool can leave a shiny surface, while a dull one might look like a troubled teenager’s room. Selecting the right tool for different materials is essential. Using the wrong tool on metal can lead to disaster, like mixing oil and water. Always match your tool to your material for the best finish!

| Tool Type | Best For | Surface Finish |

|---|---|---|

| HSS Tool | General use | Smooth |

| Carbide Tool | Hard materials | Very smooth |

| Diamond Tool | Fine finishing | Shiny |

Preparation Techniques for Lathe Work

Importance of material preparation. Techniques for achieving smoother surfaces before turning.

Preparing material is key for a great finish. Proper preparation leads to smoother surfaces, making the turning easier and more efficient. Here are some techniques:

- Clean the surface: Remove dust and debris.

- Use sandpaper: Sand the surface lightly before turning.

- Check for defects: Look for cracks or rough spots.

- Secure the material: Ensure it is tightly fastened.

These steps help achieve a fine finish, which is important for your project’s success.

Why is preparing materials important?

Material preparation prevents tool marks and ensures a clean, smooth surface. This step is crucial for quality results in lathe work.

Effective Cutting Techniques to Minimize Tool Marks

Moving speed and feed rate adjustments. Angle of tool presentation and its effects.

To get smooth surfaces, you need to adjust your cutting speed and feed rate. Faster movement can create rough spots. Slower approaches often lead to cleaner results. The angle of your tool also matters. A tilted tool can cut better than a straight one. Here are some tips:

- Change speed according to material.

- Use a steady feed rate for even cuts.

- Experiment with your tool angle for best results.

These small changes can really enhance your work!

How does speed affect tool marks?

Higher speeds can reduce tool marks by minimizing contact with the material. However, too much speed can lead to vibrations and poor finishes. Finding the right balance is key.

Polishing Techniques Post-Turning

Recommended polishing compounds and methods. When and how to apply sanding techniques.

Polishing brings out the best in your turned pieces. First, choose the right polishing compound. Carnauba wax and micro-mesh pads work wonders. Apply these compounds after sanding. Use a fine grit to smooth the surface. You can also try these methods:

- Start with 120-grit sandpaper.

- Gradually move to 220-grit.

- Finish with 400-grit for a shiny look.

Using the right technique improves the finish. Always sand in the direction of the grain. This prevents scratches and ensures a smooth surface.

What polishing compounds should I use?

Carnauba wax and micro-mesh pads are ideal for polishing turned objects. They give a beautiful shine and protect the surface.

Using Cutting Fluids for Enhanced Finish

Benefits of cutting fluids in lathe operations. Best practices for applying cutting fluids.

Cutting fluids make a big difference in lathe operations. They help keep tools cool and improve surface quality. This means less wear on tools and better finishes on the workpiece. Here are some best practices for using cutting fluids:

- Always choose the right type of fluid for your material.

- Apply fluids to areas that create the most heat.

- Use a spray system for even coverage.

- Keep fluids clean and change them regularly.

With the right cutting fluid, you can achieve smooth and precise finishes that make your work shine!

Why should you use cutting fluids in lathe operations?

Cutting fluids cool tools, reduce wear, and enhance surface quality. They prevent overheating and make machining easier.

What are the best practices for applying cutting fluids?

- Choose the right fluid.

- Target areas that generate heat.

- Ensure even application with sprays.

- Keep fluids clean for best results.

Common Mistakes to Avoid in Lathe Turning

Misalignment and its effects on tool marks. Overheating and its impact on material integrity.

Lathe turning is tricky, and mistakes can cause problems. Misalignment can lead to uneven cuts. This creates ugly tool marks. Keep tools aligned with the workpiece for a smoother finish. Overheating can also happen from too much friction. It can weaken materials. Always check speed settings to prevent heat build-up. Avoid these mistakes to improve your lathe projects!

What causes alignment issues in lathe turning?

Misalignment occurs when the workpiece is not set correctly on the lathe. This can lead to uneven cuts and tool marks. Using proper setup and checking alignment often can prevent this.

Tips to avoid overheating:

- Use appropriate speeds for the material.

- Keep tools sharp to reduce friction.

- Take breaks to cool down the workpiece.

Tools and Products for Mark Removal

Essential tools for DIY mark removal. Recommended commercial products for efficiency.

Gathering the right tools makes removing marks easier. Here are some must-haves for DIY projects:

- Sandpaper: Perfect for smoothing surfaces.

- Rubbing compound: Removes fine scratches effectively.

- Buffer/polisher: Gives a shiny finish.

- Microfiber cloths: Great for cleaning without scratching.

For quick results, consider these commercial products:

- Scratch Remover: Works well on metal surfaces.

- Wood Polish: Revives wood furniture like new.

- All-Purpose Cleaner: Useful for various marks.

What tools do you need for mark removal?

Essential tools include sandpaper, rubbing compound, and a buffer. These help remove marks quickly and cleanly.

Regular Maintenance for Lathe Tools

Importance of maintaining lathe tools. Best practices for tool upkeep to prevent future marks.

Keeping lathe tools in good shape is very important. Well-maintained tools work better and last longer. If you take care of your tools, you can avoid tool marks on your work. Here are some tips for regular maintenance:

- Clean tools after each use.

- Sharpen cutting edges often.

- Store tools in a dry place.

- Check for rust or damage regularly.

Spend just a little time on upkeep. It will save you more time later. Happy crafting!

Why is maintaining lathe tools important?

Maintaining lathe tools is important because it helps them work well and stay safe to use. Regular care reduces wear and tear, which means fewer tool marks. It also makes the tools last longer, saving money.

Best practices for tool upkeep:

- Regular cleaning.

- Consistent sharpening.

- Proper storage.

Conclusion

To remove lathe turning tool marks, use abrasive pads, sandpaper, or polishing compounds. Start with coarser grit and move to finer ones. Always keep your work surface clean. For the best results, take your time and practice these techniques. We encourage you to explore more tips online and try them out for smoother, better-looking projects!

FAQs

What Are The Most Effective Methods For Removing Lathe Tool Marks From Metal Surfaces?

To remove lathe tool marks from metal surfaces, you can use sandpaper. Start with rough paper to smooth out the marks. Then, switch to finer paper for a smooth finish. You can also use a file or a grinding tool if needed. Always be careful and wear safety gear like goggles!

How Can You Use Finishing Techniques To Minimize The Appearance Of Lathe Tool Marks?

To make lathe tool marks less visible, you can use some finishing techniques. First, sand the surface gently with fine sandpaper. This helps smooth out the bumps and marks. Next, you can apply a coat of varnish or paint. This adds shine and hides any leftover marks.

Are There Specific Abrasives Or Polishing Compounds Recommended For Smoothing Lathe-Turned Workpieces?

Yes, there are special materials we can use to smooth lathe-turned pieces. You can start with sandpaper, using finer grits as you go. After that, try polishing compounds like rubbing compound or finishing polish. These will help make your workpieces shine and feel smooth!

What Role Does Tool Geometry Play In Reducing Tool Marks During The Turning Process?

Tool geometry, or the shape of the tool, helps us create smoother surfaces when we cut materials. A sharp edge makes clean cuts, while a dull edge can leave rough marks. The angles of the tool also matter. Good angles help the tool glide over the material better, reducing scratches and bumps. When we use the right tool shape, we get a nicer finish on our work!

How Can Different Cutting Speeds And Feeds Impact The Visibility Of Tool Marks In Lathe Operations?

Cutting speeds and feeds are important when using a lathe, which is a machine that shapes metal or wood. If you cut too slowly, you might see more tool marks on the surface. This happens because the tool digs in more. If you go faster or use the right feed, the marks can be less noticeable. So, adjusting these speeds helps make smoother surfaces!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Most Effective Methods For Removing Lathe Tool Marks From Metal Surfaces? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove lathe tool marks from metal surfaces, you can use sandpaper. Start with rough paper to smooth out the marks. Then, switch to finer paper for a smooth finish. You can also use a file or a grinding tool if needed. Always be careful and wear safety gear like goggles!”}},{“@type”: “Question”,”name”: “How Can You Use Finishing Techniques To Minimize The Appearance Of Lathe Tool Marks? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make lathe tool marks less visible, you can use some finishing techniques. First, sand the surface gently with fine sandpaper. This helps smooth out the bumps and marks. Next, you can apply a coat of varnish or paint. This adds shine and hides any leftover marks.”}},{“@type”: “Question”,”name”: “Are There Specific Abrasives Or Polishing Compounds Recommended For Smoothing Lathe-Turned Workpieces? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are special materials we can use to smooth lathe-turned pieces. You can start with sandpaper, using finer grits as you go. After that, try polishing compounds like rubbing compound or finishing polish. These will help make your workpieces shine and feel smooth!”}},{“@type”: “Question”,”name”: “What Role Does Tool Geometry Play In Reducing Tool Marks During The Turning Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool geometry, or the shape of the tool, helps us create smoother surfaces when we cut materials. A sharp edge makes clean cuts, while a dull edge can leave rough marks. The angles of the tool also matter. Good angles help the tool glide over the material better, reducing scratches and bumps. When we use the right tool shape, we get a nicer finish on our work!”}},{“@type”: “Question”,”name”: “How Can Different Cutting Speeds And Feeds Impact The Visibility Of Tool Marks In Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cutting speeds and feeds are important when using a lathe, which is a machine that shapes metal or wood. If you cut too slowly, you might see more tool marks on the surface. This happens because the tool digs in more. If you go faster or use the right feed, the marks can be less noticeable. So, adjusting these speeds helps make smoother surfaces!”}}]}