Imagine stepping into a workshop filled with the smell of wood shavings and shimmering metal. You look around and see tools everywhere! It can be hard to find what you need when chaos rules your space. This is where a lathe turning tool tray comes in handy.

Have you ever spent twenty minutes searching for a single tool? It’s frustrating! Organizing your lathe turning tools not only saves time but also makes working more enjoyable. Keeping your tools organized can help you focus on your project and spark creativity.

Did you know that an organized workspace can boost your mood? A simple tool tray can change everything. Just think about how nice it would be to reach for your favorite chisel without digging through a pile of clutter. In this article, we’ll explore some fun and easy ways to organize your lathe tools. Get ready to transform your workspace!

Lathe Turning Tool Tray Organization Tips For Efficiency

Understanding the Importance of Tool Organization

Benefits of organized tools for lathe turning. Impact on productivity and safety.

Keeping tools organized helps everyone work better. An orderly lathe turning tool tray saves time and reduces frustration. Did you know that a tidy workspace can boost productivity by up to 20%? That’s like finding an extra hour in your day! Plus, with tools in their place, accidents drop significantly. Who needs a surprise visit to the first aid kit? So, let’s dive into how a neat tool tray not only keeps chaos at bay but also makes your work safer and more efficient.

| Benefits of Organization | Impact on Productivity | Effects on Safety |

|---|---|---|

| Less time wasted | Boosts efficiency | Reduces accidents |

| Easier to find | Improves workflow | Keeps everyone safe |

Essential Features of an Effective Tool Tray

Size and compartments: Finding the right dimensions. Materials and durability: Choosing the best options.

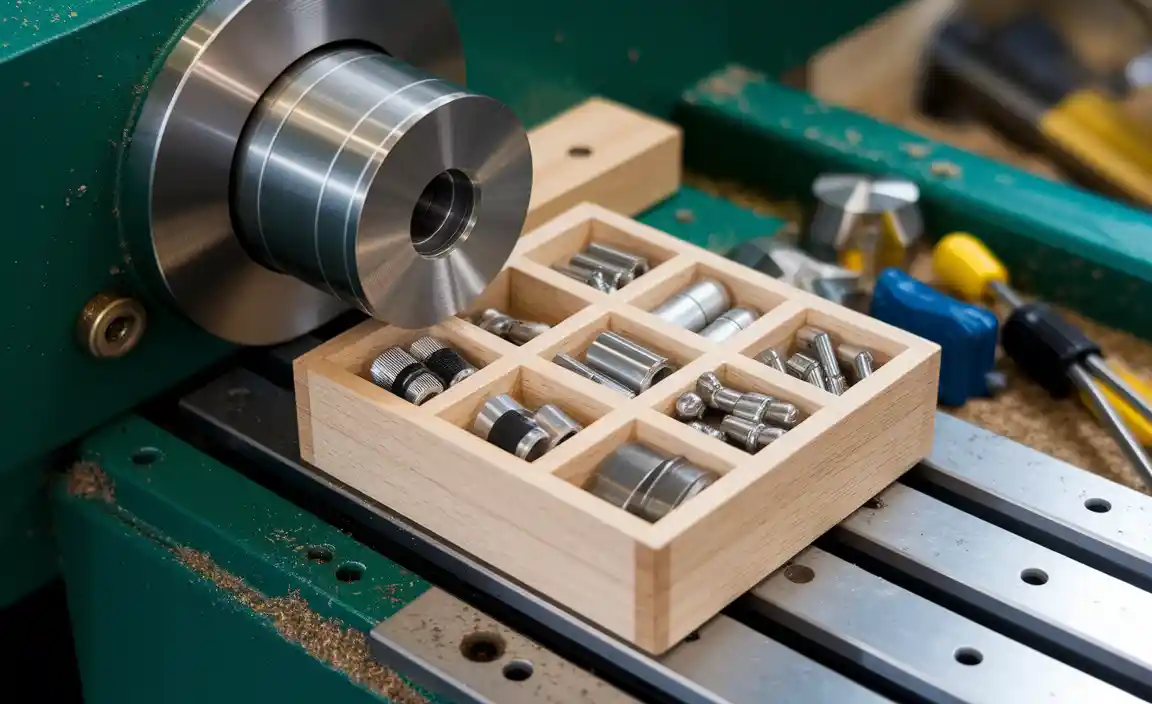

An effective tool tray must be the right size. Think about your tools and how much space they need. You want to keep everything organized. Compartments help too! They sort tools by type. This makes finding things quick and easy. Also, choose strong materials. Look for options like plastic or metal. They should last a long time even with heavy use. You want your tray to be tough and not break easily.

What size should a tool tray be?

The size should fit your tools and workspace. Measure your tools and the space where you store the tray. A good fit allows easy access and organization.

What materials are best for a tool tray?

- Plastic: Lightweight and easy to clean.

- Metal: Strong and durable for heavy tools.

- Wood: Stylish, but can wear down quickly.

DIY Tool Tray Organization Solutions

Stepbystep guide to building your own tool tray. Costeffective materials and tools needed.

Building your own tool tray can be fun and useful! Start by gathering materials like wood or plastic, which won’t cost you an arm and a leg. Measure your tools to make sure everything fits snugly. A few nails and some screws are usually all you need to hold everything together. Follow these basic steps:

| Step | Description |

|---|---|

| 1 | Gather materials. |

| 2 | Measure and cut pieces. |

| 3 | Assemble the tray. |

| 4 | Finish it up with paint or varnish. |

Your very own tool tray will help keep things tidy and make you feel like a woodworking superhero! Plus, you can impress your friends with your mad DIY skills!

Commercial Tool Tray Options: What to Consider

Review of popular commercial tool trays for lathe tools. Pros and cons of buying versus DIY.

Choosing the right tool tray for lathe tools can make a big difference. Many store options provide great designs that save space and keep tools organized. Popular brands often offer sturdy trays with easy access. However, there are pros and cons.

- Pros of Buying:

- Convenient and ready to use.

- Often comes with warranties.

- Tested for quality and durability.

- Cons of Buying:

- Can be more expensive.

- May not fit all tools perfectly.

On the other hand, DIY options are fun. You can customize them to fit your tools. Just remember, it might take more time. Think about what works best for you!

What are the benefits of commercial tool trays?

Commercial tool trays offer reliability and ease of use. They are ready-made, saving time and effort in organizing.

Popular Brands to Consider:

- Woodpeckers – known for precision.

- Veritas – great for organizing small tools.

- Rockler – offers multiple sizes.

Customizing Your Tool Tray Layout

Tailoring the layout to your specific workflow. Techniques for maximizing space efficiency.

Arranging your tool tray can help you work better. Start by placing tools you use most often within reach. Consider your personal style; everyone works differently. Use small trays or dividers to keep things tidy. This makes finding tools quick and easy.

- Group similar tools together.

- Use labels for clarity.

- Leave space for new tools.

Efficient use of space keeps your area organized and neat. A clean workspace lets you focus on the task. Good order can improve your workflow by up to 30%!

How can I make my tool tray more efficient?

To make your tool tray more efficient, focus on organization and accessibility. Keep frequently used tools within arm’s reach and use dividers to avoid clutter.

Maintenance Tips for Tool Trays and Tools

Routine checks and cleaning practices. Best practices for tool preservation.

To keep your tool tray and tools in great shape, regular checks are key. Look for rust, dirt, or wear. Clean tools often with a soft cloth. This helps them last longer. Use a light oil to keep them shiny.

Here are some helpful tips:

- Store tools dry to prevent rust.

- Organize tools neatly to find them easily.

- Check for damage before use.

- Replace worn-out tools promptly.

Taking care of your tools saves money and time. Think of it as giving them a spa day!

How often should tools be checked?

You should check your tools at least once a month. Regular checks prevent bigger problems later.

Real-Life Case Studies and Examples

Successful tool organization in various workshops. Interviews with experienced woodturners on their setups.

Many workshops show how proper tool organization helps workers. For example, some woodturners have smart setups that keep everything neat. They use simple trays and racks to store their tools. This makes finding the right tool easy and fast. Experienced woodturners shared tips that can help anyone.

- Use labeled trays for quick access.

- Group similar tools together.

- Keep frequently used tools within arm’s reach.

- Regularly clean and reorganize your space.

A clean workspace can boost happiness and productivity.

What are benefits of tool organization?

Good tool organization saves time, reduces stress, and increases safety. Clean spaces help workers focus better. They can easily spot the tool they need.

Future Trends in Tool Organization Solutions

Innovations in tool tray design. The role of technology in tool management.

New ideas are shaping how we organize our tools. Imagine a world where tool trays have built-in sensors! This tech tracks your lathe tools and tells you when to sharpen them. It’s like having a tool butler, minus the fancy bowtie! Innovative designs also create space for each tool, helping you find them quickly. Forget the mess—let’s turn that chaos into a smooth-running machine!

| Innovation | Description |

|---|---|

| Smart Tool Trays | Track & manage tool usage |

| Magnetic Holders | Keep tools secure & easy to grab |

| Eco-friendly Materials | Use sustainable materials for trays |

Conclusion

In summary, organizing your lathe turning tools in a tray helps keep them neat and easily accessible. Use labeled sections for each tool type. You can also use foam or magnets to secure them. Keeping a tidy workspace improves your efficiency and focus. Try these tips today to enhance your lathe projects. For more ideas, check out additional resources!

FAQs

What Are The Best Materials To Use For Constructing A Lathe Turning Tool Tray For Durability And Ease Of Cleaning?

To make a lathe turning tool tray that lasts a long time and is easy to clean, use plastic or stainless steel. Plastic is lightweight and won’t rust, making it easy to handle. Stainless steel is very strong and can be wiped clean easily. Both materials are great choices to keep your tools safe and tidy!

How Can I Effectively Categorize My Lathe Tools In A Tray For Quick Access And Organization?

You can organize your lathe tools by grouping them by type. For example, put all cutting tools in one section. Next, keep measuring tools together in another spot. Use labels or stickers to mark each section. This way, you can find your tools quickly when you need them!

What Are Some Creative Designs For Tool Trays That Maximize Space And Minimize Clutter In A Small Workshop?

You can build a hanging tool tray that hangs on the wall. This saves table space. You could also try stacking trays that fit on top of each other. This way, we can store more tools in a small area. Finally, use magnetic strips to hold small tools up on the wall. This keeps them easy to reach and off the table!

How Can I Incorporate Labeling Systems In My Lathe Tool Tray To Improve Organization And Efficiency While Working?

You can use labels to organize your lathe tool tray. First, get some small stickers or tags. Then, write what each tool is on a label. Place the labels where the tools belong. This will help you find your tools quickly and keep everything tidy!

What Features Should I Consider Including In A Custom Lathe Tool Tray To Accommodate A Variety Of Tool Sizes And Types?

When making a custom lathe tool tray, think about different sizes. You can add spaces for small and big tools. Use different slots or sections so tools stay organized. You might want to have some padding to keep tools safe. Lastly, consider a way to label each section for easy finding.