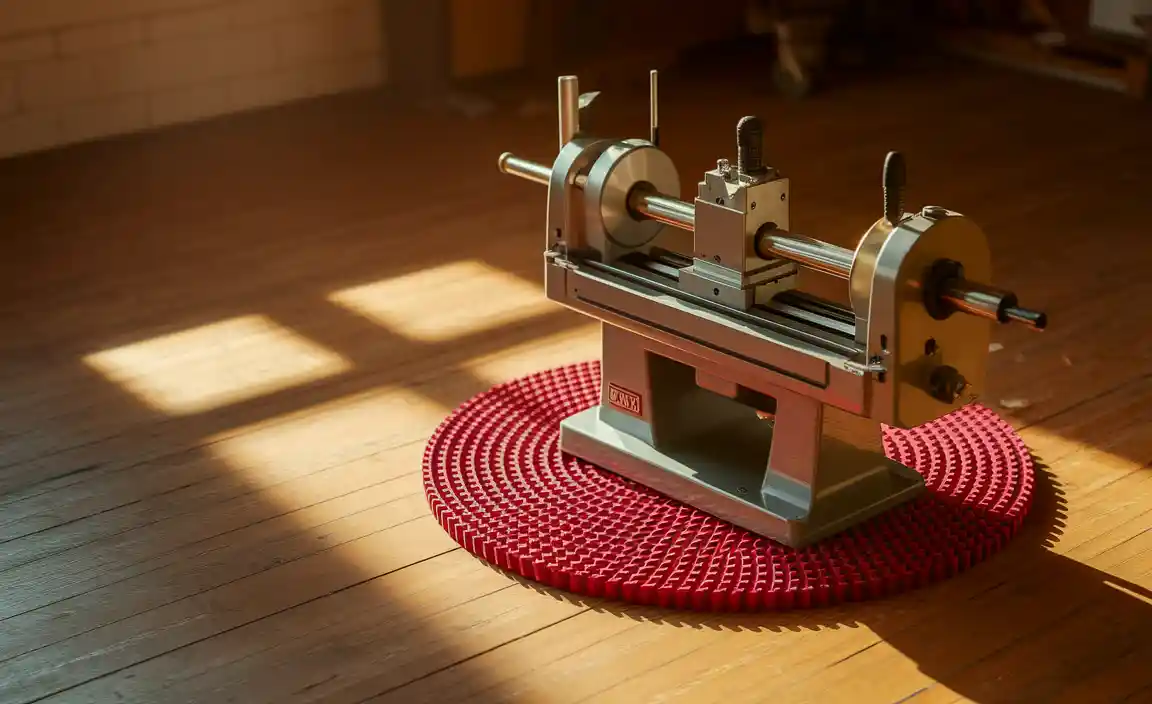

Have you ever noticed how machines can shake and rattle when they work? This is especially true for lathes. They create beautiful shapes but often come with a downside: vibration. This is where a lathe turning vibration dampening mat comes in handy.

Imagine you’re in your workshop, ready to start carving. Suddenly, excessive vibrations make your work tough and messy. What if there was a simple solution to reduce those shakes? Using a dampening mat can make a significant difference.

These mats help absorb vibrations, making it easier to focus on your projects. They create a stable surface that keeps your tools and materials steady. Plus, they can even protect your floor and equipment from damage.

Did you know that some mats can even reduce noise? That’s right! A lathe turning vibration dampening mat can make your workspace quieter and more enjoyable.

With the right mat, you can turn with confidence and precision. Isn’t it exciting to think about how a simple addition could transform your lathe experience? Let’s dive deeper into the benefits and features of these interesting mats.

Lathe Turning Vibration Dampening Mat: Essential Benefits And Tips

The Role of Vibration in Lathe Operations

How vibration affects precision and surface finish. Consequences of excessive vibration on tools and materials.

Vibration can be a sneaky little gremlin in lathe operations. It might seem harmless but it plays a big role in precision and surface finish. Even the tiniest shake can lead to a rough surface or an uneven cut – and nobody wants that! If vibration gets too wild, it can wear out tools and damage materials faster than you can say “lathe.” Think of it as your tool’s way of singing the blues!

| Effect of Vibration | Consequences |

|---|---|

| Poor Surface Finish | Rough textures |

| Loss of Precision | Inaccurate dimensions |

| Tool Wear | Increased replacements |

So, it’s crucial to keep vibration under control. Tools and materials deserve their moment of glory without any unwanted dance moves!

What is a Vibration Dampening Mat?

Definition and purpose of vibration dampening mats. Different materials used in dampening mats.

A vibration dampening mat reduces noise and vibrations. It helps machines run smoothly. With less shaking, the equipment works better and lasts longer. These mats are important for places like workshops and factories.

- Common materials for these mats include:

- Rubber: Absorbs shocks well.

- Foam: Lightweight and easy to use.

- Fiberglass: Strong and durable.

This makes them perfect for machinery like lathes. They help keep everything steady and quiet.

What materials can be used for vibration dampening mats?

Rubber, foam, and fiberglass are popular choices for vibration dampening mats. They each offer unique benefits for dampening vibrations.

Benefits of Using Vibration Dampening Mats

Enhanced accuracy and surface quality of machined parts. Reduced wear and tear on machines and tools.

Using vibration dampening mats offers many great benefits. First, they help improve the accuracy and surface quality of machined parts. This means better-fitting pieces in your projects. Second, they reduce wear and tear on machines and tools. This can lead to lower costs for repairs and replacements. Overall, using these mats makes work easier and more efficient.

What are the main benefits of vibration dampening mats?

Vibration dampening mats help in two major ways:

- Enhanced accuracy: They keep machines steady for precise work.

- Reduced wear and tear: They protect tools, helping them last longer.

How to Choose the Right Vibration Dampening Mat

Key factors to consider: material, thickness, and density. Evaluating the compatibility with specific lathe models.

Choosing the right vibration dampening mat is crucial for effective lathe performance. Key factors include the material, thickness, and density of the mat. These aspects help reduce noise and vibrations. Also, ensure the mat is compatible with your lathe model. A good fit means better results!

What should I consider for my lathe mat?

Think about these factors:

- Material: Look for rubber or foam for the best damping effects.

- Thickness: Thicker mats often reduce vibrations better.

- Density: A denser mat usually absorbs more shock.

Installation and Maintenance of Vibration Dampening Mats

Stepbystep guide to installing mats under lathes. Tips for maintaining and ensuring longevity of mats.

Installing a vibration dampening mat is easy! Follow this simple guide:

- Clean the floor where the lathe will sit.

- Unroll the mat carefully.

- Place the mat under the lathe, making sure it’s flat.

- Check for any wrinkles and smooth them out.

- Secure the lathe on top of the mat.

To keep the mat in great shape, remember:

- Clean the mat regularly with a damp cloth.

- Don’t place heavy items on it for long periods.

- Store it indoors to avoid damage.

How to ensure longevity of the dampening mat?

Check the mat weekly for any signs of wear. Small cracks can grow larger, so spot them early. Replace the mat if it gets too worn. Care helps your mat last longer!

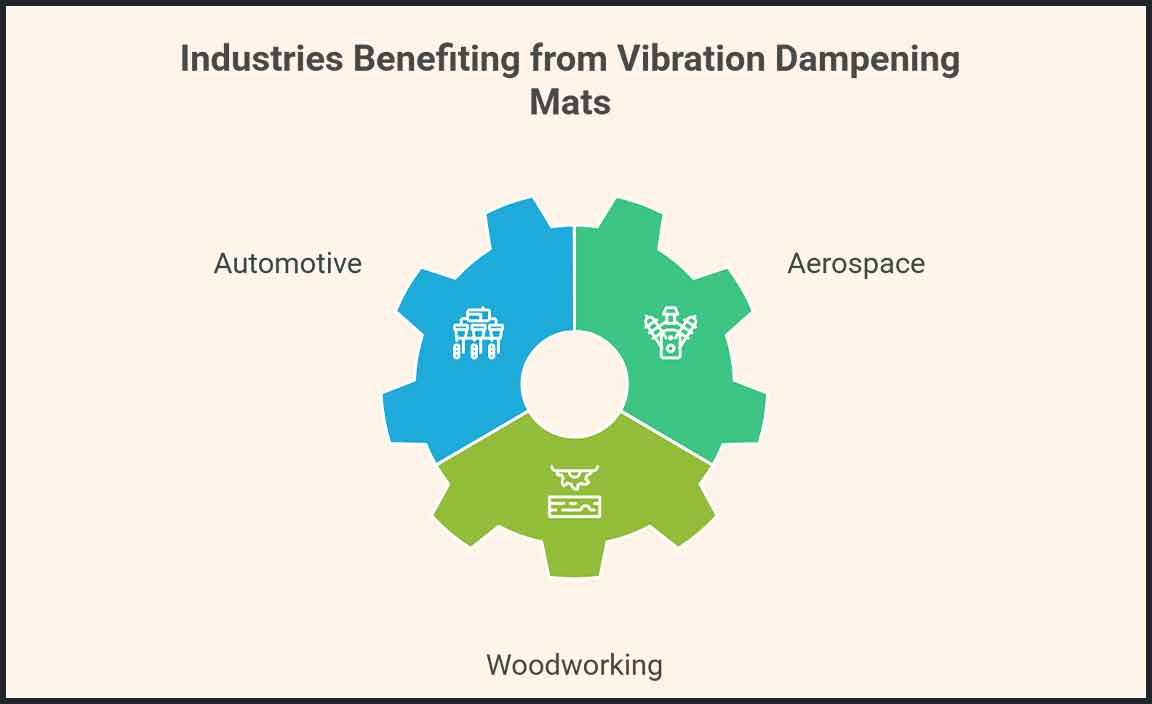

Real-World Applications and Case Studies

Examples of industries benefiting from vibration dampening mats. Case studies showcasing improvements in machining performance.

Many industries enjoy the perks of using vibration dampening mats. These mats help reduce noise and improve machine performance. For example, the automotive sector found that using these mats helped machines run smoother and longer. A case study showed that one factory increased production speed by 25% just by adding these mats. Imagine a lathe that spins like a dancer instead of a wobbly toddler!

| Industry | Benefit |

|---|---|

| Automotive | Improved machine efficiency |

| Aerospace | Reduced noise levels |

| Woodworking | Longer tool life |

With such great results, who wouldn’t want to dance along to the rhythm of stability and precision?

Future Trends in Vibration Control for Lathing

Innovations in vibration dampening technology. Predictions on the evolution of lathe operations and materials.

New technology is changing the way we control vibration in lathing. Early research shows that advanced vibration dampening materials will be key. These materials can absorb vibrations, making lathing smoother and quieter. Predictions suggest lathes will become more accurate and safer to use. Machines will also be lighter and easier to handle. Here are some possible advancements:

- Improved materials for better noise reduction

- Smart sensors for real-time monitoring

- Automated systems to adjust settings

These innovations will make lathing more efficient and enjoyable.

What are the benefits of vibration control in lathing?

Vibration control helps reduce wear and tear on machines. It also decreases mistakes in cutting, leading to cleaner projects.

Conclusion

In summary, a lathe turning vibration dampening mat can greatly improve your work experience. It reduces vibrations and protects your machine. This helps you achieve better accuracy and a smoother finish. If you want to work safely and efficiently, consider getting one. For more details, check online resources or ask your local supplier for recommendations. Happy turning!

FAQs

What Materials Are Commonly Used In The Construction Of Lathe Turning Vibration Dampening Mats, And How Do They Affect Performance?

Lathe turning vibration dampening mats are usually made from rubber, foam, or a mix of both. These materials help to soak up the shakes and bumps from machines. By doing this, they make it easier for you to work without distractions. A good mat helps your tools work better and last longer. It also protects the floor and reduces noise.

How Does The Use Of A Vibration Dampening Mat Impact The Precision And Quality Of Machined Parts During Lathe Turning?

A vibration dampening mat helps reduce wobbles and shakes from machines. When we use it during lathe turning, it keeps the parts steady. This steadiness means the pieces are shaped more accurately. As a result, we get better-quality parts. So, using the mat helps make our work stronger and more precise!

Are There Specific Thicknesses Or Densities Of Vibration Dampening Mats That Are Recommended For Different Types Of Lathes Or Machining Tasks?

Yes, different lathes and machines need different mats. For heavy machines, thicker mats around one inch are better. Lighter machines can use mats that are half an inch thick. Denser mats help absorb more vibrations, which is good for keeping everything steady. Always check your machine’s guide for the best mat size!

What Are The Signs That A Lathe Turning Machine May Benefit From The Addition Of A Vibration Dampening Mat?

If your lathe machine shakes or wobbles a lot while running, it may need a dampening mat. You might notice that your workpieces come out uneven or rough. If you feel strong vibrations when you touch the machine, it’s a sign too. Adding a mat can help keep everything steady and make your work smoother.

How Do Vibration Dampening Mats Compare To Other Vibration Isolation Methods For Lathes In Terms Of Cost And Effectiveness?

Vibration dampening mats are usually cheaper than other solutions, like special mounts or pads. They work well to reduce shaking from lathes. However, some fancy mounts might work even better but cost more. If you want a good balance of price and help, mats are a smart choice. You can easily find and use them for your lathe.

Resource:

-

Noise Control Strategies in Workshops: https://www.osha.gov/noise

-

How Rubber Absorbs Vibration in Engineering: https://www.sciencedirect.com/science/article/pii/S026382231731244X

-

Workshop Ergonomics and Tool Safety: https://www.ccohs.ca/topics/hazards/ergonomic/tools/

-

Smart Sensors in Modern Machinery: https://www.nature.com/articles/s41598-019-40431-0