Have you ever wondered how metal parts are made? A metal lathe is a powerful tool that turns raw metal into beautiful shapes. In this lathe tutorial, we’ll explore how to use a metal lathe effectively.

What if you could design your own parts using CAD? CAD stands for Computer-Aided Design. It helps you create accurate plans for your projects. This article will guide you through the steps of using CAD with a metal lathe.

Imagine creating a unique metal piece that fits your vision perfectly. That’s the magic of combining lathe skills with CAD design. Did you know that the first lathes were made thousands of years ago? They have come a long way since then!

Get ready to learn some exciting tips and tricks. With the right guidance, you can master the art of metalworking. Let’s dive into the world of lathes and design!

Comprehensive Lathe Tutorial: Metal Lathe Cad Design Guide

Lathe Tutorial: Metal Lathe CAD Design

Want to create amazing metal parts? A lathe tutorial can help you master this skill! You’ll learn how to use a metal lathe for precise cutting. CAD design tools make planning your projects easier and more accurate. Imagine turning a simple block of metal into a beautiful piece! By following step-by-step guides, anyone can become skilled at lathe work. Discover the exciting world of metalworking and let your creativity shine!Understanding the Basics of Metal Lathes

Definition and purpose of metal lathes. Key components and their functions.Metal lathes are like big spinning friends for metal! They help shape and cut metal into different forms. The main parts include the spindle, which holds the metal, and the cutting tool, which does the magic. Think of the lathe as a giant pencil sharpener, but for metal! It helps create everything from toy parts to car engines. Knowing these key components is the first step to becoming a metal master!

| Component | Function |

|---|---|

| Spindle | Holds and spins the metal workpiece |

| Cutting Tool | Shapes the metal while it spins |

| Tailstock | Supports the workpiece during cutting |

| Bed | Holds everything in place |

Benefits of Using CAD in Metal Lathe Design

Advantages of CAD over traditional drafting. Enhanced precision and efficiency in design.Using CAD for metal lathe design offers many benefits. It helps create designs that are more accurate than traditional methods. With CAD, changes happen faster, saving time and energy. Here are some key advantages:

- High precision: CAD designs are exact, which leads to better products.

- Increased efficiency: Designers can work quicker and easily share files.

- Easier updates: Changes can be made in a few clicks, not by hand.

These benefits make CAD an important tool in modern designing.

Why is CAD better than hand drafting?

CAD provides greater speed and accuracy, making it easier to create complex designs.Essential Design Principles for Metal Lathe Projects

Importance of dimensional accuracy. Key design considerations for different metal types.Creating metal lathe projects requires serious attention to dimensional accuracy. Imagine trying to fit a square peg in a round hole—yikes! You want every piece to fit perfectly. Each metal type has its quirks. For example, softer metals are easier to shape but may need gentle hands. Here’s a quick look at what to remember:

| Metal Type | Design Consideration |

|---|---|

| Aluminum | Lightweight, easy to cut |

| Steel | Strong, needs more power |

| Copper | Good conductor, soft but tricky |

By knowing these tips, you can whip up some fantastic projects without losing your mind—or fingers!

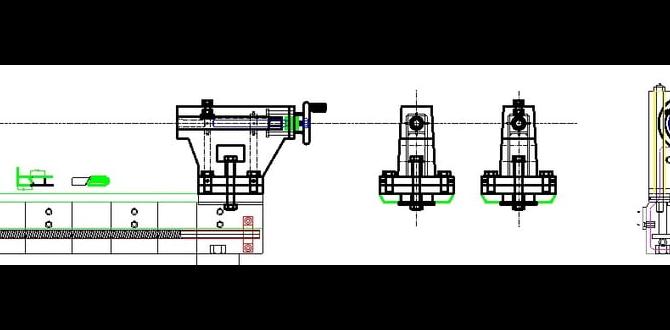

Creating a Basic Metal Lathe Design in CAD

Stepbystep process for beginners. Tips for optimizing design workflow.To create a basic design for a metal lathe in CAD, follow these steps:

- Start by sketching the lathe layout.

- Add dimensions to your design.

- Include important components like the motor and chuck.

- Finalize the design with details like materials.

For a better workflow, remember to:

- Use layers to organize parts.

- Save your work often.

- Use shortcuts for faster changes.

These tips can help beginners work smarter and create better designs!

What are the key steps to designing a metal lathe?

The key steps include sketching, adding dimensions, including components, and finalizing details.

Advanced Techniques for Metal Lathe CAD Design

Incorporating complex geometries. Using assemblies and constraints effectively.Designing complex shapes in metal lathe CAD can feel like solving a puzzle. Using advanced techniques makes it easier and fun. For example, you can create intricate geometries that look cool and perform great. It’s like adding a twist to your favorite dance moves! Another tip is to master assemblies and constraints. This helps parts fit together perfectly, just like pieces of a jigsaw puzzle. Remember, a well-planned design can save you from headaches later!

| Technique | Description |

|---|---|

| Complex Geometries | Create unique shapes that enhance functionality. |

| Assemblies | Combine parts to visualize the final product. |

| Constraints | Set limitations to ensure precise fit and movement. |

Common Mistakes to Avoid in Metal Lathe CAD Design

Frequent design errors and how to prevent them. Importance of validating designs before production.Designing a metal lathe can be tricky. Many people make common mistakes that can lead to failed projects. Pay attention to these frequent errors:

- Ignoring dimensions can cause pieces to not fit together.

- Rushing the design means missing important details.

- Not checking material properties can lead to weak parts.

To avoid these issues, always validate your designs before production. This means testing your design on paper first. It saves time and money. Remember, a good design makes a great project!

What are common mistakes in CAD design for metal lathes?

Common mistakes include ignoring dimensions, rushing designs, and overlooking material properties. Always double-check your work to prevent these errors.

Real-World Applications of Metal Lathe CAD Designs

Examples of industry applications. Case studies showcasing successful projects.Metal lathe CAD designs find their way into various industries. For example, the automotive industry relies on these designs for creating custom parts. A successful case study involves a local garage that improved engine performance by 30% using tailored CAD designs. In the aerospace sector, companies used these designs to reduce airplane weight, making flights safer and cheaper. It’s clear that metal lathe CAD isn’t just a classroom tool; it’s a real-world superhero, saving time and boosting creativity!

| Industry | Application Example | Outcome |

|---|---|---|

| Automotive | Custom engine parts | 30% performance boost |

| Aerospace | Lightweight components | Safer, cheaper flights |

Resources for Further Learning and Improvement

Recommended books, courses, and online resources. Community forums and networking opportunities.Learning doesn’t stop here! To get better at using lathe tutorial metal lathe CAD design, check out these helpful resources:

- Books: Look for beginner books on metalworking and CAD design.

- Online Courses: Websites like Coursera and Udemy offer great classes.

- Community Forums: Join forums like Reddit or local maker spaces to ask questions.

- Networking: Attend workshops or meetups to connect with experts.

Each resource can help you take your skills to the next level!

What are the best resources to learn about lathes?

The best resources include books on metalworking, online courses from sites like Coursera, and community forums for hands-on advice. You can also join local maker spaces to meet fellow enthusiasts.

Conclusion

In conclusion, mastering a metal lathe requires practice and understanding of CAD design. You can create precise parts and projects with the right techniques. Start with basic tutorials to build your skills. Experiment with different designs and tools. Remember, practice makes perfect! Explore more online resources to expand your knowledge and grow as a maker. Happy crafting!FAQs

What Are The Essential Cad Software Options Available For Designing Parts To Be Machined On A Metal Lathe?Some good computer programs for designing parts for a metal lathe are AutoCAD, SolidWorks, and Fusion 360. You can use AutoCAD for 2D designs, while SolidWorks is great for 3D models. Fusion 360 combines both features and is easy to use. Each of these programs helps you create the designs you need to make metal parts.

How Can I Convert Cad Designs Into G-Code For Programming A Cnc Metal Lathe?To convert your CAD designs into G-code for a CNC metal lathe, you first need special software. This software takes your design and translates it into a language the lathe can understand. You can use programs like Fusion 360 or Mach3 for this. After your design is ready, you simply save it as G-code. Then, you can load this code into your CNC lathe to make your metal parts!

What Best Practices Should I Follow When Designing Parts In Cad For Optimal Machining On A Metal Lathe?When you design parts in CAD for a metal lathe, keep your shapes simple. Use clear lines and avoid small details. Make sure your part has enough space for tools to work. Also, check that the measurements are right. This helps the lathe make your part better and faster!

How Do I Ensure My Cad Design Accounts For Tool Clearances And Proper Cutting Parameters When Turning Metal?To make sure your CAD design has enough space for the tools, check the tool’s size. You should draw extra space around the parts where the tool works. For cutting metal, use the right speed and pressure for the tool you choose. Always test your design with a small piece before working on the real metal. This helps you avoid mistakes and get better results!

What Common Mistakes Should Be Avoided When Creating Cad Models Specifically For Metal Lathe Applications?When making CAD models for metal lathes, you should avoid a few common mistakes. First, don’t forget to check the sizes. If your measurements are wrong, the part won’t fit. Also, be careful with the details. Small features can be hard to cut on a lathe. Finally, remember to save your work often. Losing your progress can be frustrating!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Cad Software Options Available For Designing Parts To Be Machined On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some good computer programs for designing parts for a metal lathe are AutoCAD, SolidWorks, and Fusion 360. You can use AutoCAD for 2D designs, while SolidWorks is great for 3D models. Fusion 360 combines both features and is easy to use. Each of these programs helps you create the designs you need to make metal parts.”}},{“@type”: “Question”,”name”: “How Can I Convert Cad Designs Into G-Code For Programming A Cnc Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To convert your CAD designs into G-code for a CNC metal lathe, you first need special software. This software takes your design and translates it into a language the lathe can understand. You can use programs like Fusion 360 or Mach3 for this. After your design is ready, you simply save it as G-code. Then, you can load this code into your CNC lathe to make your metal parts!”}},{“@type”: “Question”,”name”: “What Best Practices Should I Follow When Designing Parts In Cad For Optimal Machining On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you design parts in CAD for a metal lathe, keep your shapes simple. Use clear lines and avoid small details. Make sure your part has enough space for tools to work. Also, check that the measurements are right. This helps the lathe make your part better and faster!”}},{“@type”: “Question”,”name”: “How Do I Ensure My Cad Design Accounts For Tool Clearances And Proper Cutting Parameters When Turning Metal? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your CAD design has enough space for the tools, check the tool’s size. You should draw extra space around the parts where the tool works. For cutting metal, use the right speed and pressure for the tool you choose. Always test your design with a small piece before working on the real metal. This helps you avoid mistakes and get better results!”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Creating Cad Models Specifically For Metal Lathe Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making CAD models for metal lathes, you should avoid a few common mistakes. First, don’t forget to check the sizes. If your measurements are wrong, the part won’t fit. Also, be careful with the details. Small features can be hard to cut on a lathe. Finally, remember to save your work often. Losing your progress can be frustrating!”}}]}