Have you ever wondered how metal shapes from raw blocks into finely crafted tools? A lathe can do just that! It’s a magical machine that spins metal, helping you create precise parts. But there’s more to using a lathe than just turning metal. Understanding torque is key to successful projects.

Imagine you want to make a shiny new handle for your favorite tool. You need to ensure you have the right torque settings on your lathe. Too much torque can damage your piece, while too little can lead to mistakes. This balance is what makes a metal lathe so fascinating!

In this tutorial, we will explore how to master your lathe. We’ll cover vital steps to get the best results. You’ll learn about lathe operation, torque settings, and safety tips. Get ready to dive into the exciting world of metalworking!

Comprehensive Lathe Tutorial: Mastering Metal Lathe Torque

Lathe Tutorial: Metal Lathe Torque Explained

Understanding metal lathe torque is essential for every aspiring machinist. Torque helps control how fast or slow the lathe turns. Did you know that the right torque can prevent damage to your tools? This tutorial teaches you about adjusting torque settings based on material type. It covers tips for selecting the right speed and power for different tasks too. With practical examples, you’ll learn how to make your lathe work effectively. Get ready to make precision cuts!Understanding Metal Lathes

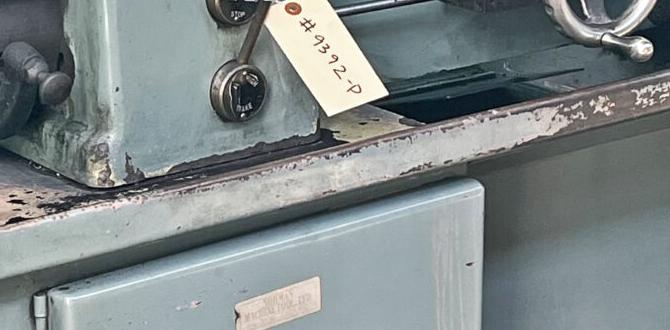

Definition and purpose of metal lathes. Different types of metal lathes and their applications.A metal lathe is a machine that shapes metal into useful objects. It spins the metal while tools cut, slice, or smooth it. Imagine a giant pencil sharpener, but instead of wood, it works with steel! There are different types of metal lathes like CNC lathes for precise work and bench lathes for smaller tasks. Each type has its own fun features, like digital displays that make “guessing” a thing of the past.

| Type of Lathe | Application |

|---|---|

| CNC Lathe | For precise machining. |

| Bench Lathe | For small parts and hobbies. |

| Toolroom Lathe | For detailed tool making. |

So whether you’re building a rocket or just sharpening a pencil, there’s a lathe for that!

Basics of Torque in Metal Lathing

Definition of torque and its importance in machining. Factors affecting torque in metal lathes.Torque is the twist that helps machines work. In machining, torque is very important. It ensures the lathe can cut metal smoothly. If the torque is too low, the machine may struggle. Factors affecting torque include:

- Material type

- Tool sharpness

- Spindle speed

- Workpiece diameter

Each factor plays a role in how well the lathe performs. Higher torque means better cutting and less wear on the tools.

What is torque in metal lathes?

Torque in metal lathes is the force that causes rotation. It helps the tool cut through materials effectively.

Calculating Torque for Metal Lathes

Formula for calculating torque. Practical examples related to metal lathing tasks.To find the torque in metal lathes, use the formula: Torque = Force x Distance. This means you multiply the force applied by the distance from the center of rotation. For example:

- If you use a force of 10 pounds at a distance of 2 feet, then torque is 20 foot-pounds.

- If you push with 5 pounds at 4 feet away, torque is 20 foot-pounds, too!

Understanding torque helps you use a lathe safely and effectively. It makes cutting easier and improves your results.

Why is Calculating Torque Important?

Calculating torque is key for balancing weight and speed. It allows you to run your lathe safely and efficiently, avoiding accidents and damage.

Torque Settings and Their Impact

Recommended torque settings for various materials. How incorrect torque settings can affect machining results.Choosing the right torque settings is like picking the perfect toppings for pizza. Too little torque, and your work might fall apart. Too much, and you’ll ruin the fun! For metals like aluminum, a recommended torque is around 40-50 Nm, while for steel, you might want to amp it up to 60-70 Nm. Check out the table below to get your numbers straight:

| Material | Recommended Torque (Nm) |

|---|---|

| Aluminum | 40-50 |

| Steel | 60-70 |

| Brass | 30-40 |

Incorrect settings lead to poor machining results. Parts might break or wear out too fast. So, make sure your torque is just right, or you might end up with a sad little pile of metal shavings instead of the masterpiece you wanted!

Techniques for Adjusting Torque

Methods to adjust torque on different lathe models. Tips for achieving optimal torque settings during operation.Adjusting torque on different lathe models is crucial for smooth operation. Various models have unique methods. Here are some tips:

- Check the manufacturer’s manual for specific settings.

- Use a torque wrench for precise adjustments.

- Monitor the machine’s response during operation.

- Keep the lathe clean and well-lubricated.

With simple tweaks, you can achieve optimal torque settings. This keeps your lathe running well and your project going smoothly.

How do you adjust torque on a lathe?

To adjust torque on a lathe, use the adjustable tension knobs or handles on your model. Carefully turn these knobs while observing the lathe’s response. Regular checks are important for best results.

Common Issues Related to Torque in Metal Lathing

Identifying signs of improper torque. Troubleshooting techniques to resolve torquerelated issues.When working with a metal lathe, improper torque can lead to some quirky problems. You might notice things aren’t turning right—or your project feels wobbly, like a dog on a skateboard! Some common signs include unusual vibrations or noise. To fix these torque issues, check settings and make sure everything is snug. Adjust your tools, or even the machine’s speed. A well-tuned lathe runs smoother than a buttered otter!

| Common Torque Issues | Signs | Troubleshooting Tips |

|---|---|---|

| Over-tightened settings | Excessive vibrations | Loosen slightly and test again |

| Under-tightened settings | Wobbly workpiece | Secure with proper tension |

| Incorrect speed | Strange sounds | Adjust to the right RPM |

Safety Considerations When Working with Metal Lathes

Importance of safety gear and precautions. Best practices for safe lathe operation and torque management.Working with metal lathes can be fun, but safety comes first. Always wear protective gear like goggles and gloves. This gear guards you against flying debris and sharp edges. When operating the lathe, keep your hands clear and stay focused. Remember, a distracted worker is a recipe for disaster—like trying to eat spaghetti with chopsticks! Here are some essential safety practices:

| Safety Gear | Best Practices |

|---|---|

| Goggles | Keep hands clear of moving parts |

| Gloves | Use proper settings for torque |

| Ear protection | Stay alert and focused |

By following these guidelines, you can ensure a safe and enjoyable lathe experience. Always remember, safety is no accident—unlike that time you tried to ride a unicycle down the stairs!

Conclusion

In summary, mastering a metal lathe requires understanding torque and how it affects your work. You should practice adjusting torque settings for better results. Always prioritize safety and follow instructions closely. For more tips and techniques, consider exploring additional lathe tutorials online. With practice, you’ll improve your skills and create amazing projects. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tutorial, Specifically Focusing On Metal Lathe Torque:Sure! Here are five questions about using a lathe. 1. What is torque? Torque is the twist or turning power you use on a lathe. 2. Why is torque important? Torque helps the lathe cut metal smoothly and safely. 3. How do you measure torque? You can measure torque with a special tool called a torque wrench. 4. Can you adjust the torque? Yes, you can change the torque settings on the lathe to fit your work. 5. What happens if torque is too low? If torque is too low, the lathe won’t cut well and might get stuck.

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Torque Requirements When Machining Different Materials On A Metal Lathe?When you use a metal lathe, the type of material affects how much torque you need. Harder materials, like steel, need more force to cut than softer ones, like aluminum. The shape of the tool and how fast you turn it also matter. If the tool is dull, it takes more torque to cut. So, choosing the right material and tool is important for smooth machining.

How Do You Calculate The Optimal Torque Settings For A Specific Cutting Operation On A Metal Lathe?To find the best torque settings for a metal lathe, you need to consider a few things. First, think about the type of metal you are cutting. Different metals need different amounts of force. Next, check the size of the tool you are using. The tool size can affect how much torque you need. Finally, you can test different settings and see which one works best. Always remember to be safe while testing!

What Are The Consequences Of Inadequate Torque On The Cutting Tool During The Lathe Machining Process?If the cutting tool doesn’t have enough torque, it won’t work well. The tool might slip or get stuck. This can cause bad cuts on the material you’re shaping. It might even break the tool or make it wear out faster. Overall, you’ll end up with a messy job and wasted time.

How Can You Adjust The Speed And Torque Settings On A Metal Lathe To Accommodate Various Threading Operations?To adjust the speed on a metal lathe, you can turn a knob or change a switch. Higher speed helps you cut threads faster, while lower speed gives you more control. To change torque, or turning power, you might need to switch gears or settings. These changes help us make different types of threads more easily. Always check the manual for your specific lathe for exact instructions.

What Safety Precautions Should Be Taken To Prevent Torque-Related Issues While Operating A Metal Lathe?To stay safe while using a metal lathe, always wear safety glasses. Make sure your hair and clothes are away from the machine. Check the tools and parts before starting to ensure they are clean and secure. Use both hands to hold the workpiece steady. Finally, keep a safe distance from moving parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tutorial, Specifically Focusing On Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about using a lathe. 1. What is torque? Torque is the twist or turning power you use on a lathe. 2. Why is torque important? Torque helps the lathe cut metal smoothly and safely. 3. How do you measure torque? You can measure torque with a special tool called a torque wrench. 4. Can you adjust the torque? Yes, you can change the torque settings on the lathe to fit your work. 5. What happens if torque is too low? If torque is too low, the lathe won’t cut well and might get stuck.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Torque Requirements When Machining Different Materials On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, the type of material affects how much torque you need. Harder materials, like steel, need more force to cut than softer ones, like aluminum. The shape of the tool and how fast you turn it also matter. If the tool is dull, it takes more torque to cut. So, choosing the right material and tool is important for smooth machining.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Optimal Torque Settings For A Specific Cutting Operation On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best torque settings for a metal lathe, you need to consider a few things. First, think about the type of metal you are cutting. Different metals need different amounts of force. Next, check the size of the tool you are using. The tool size can affect how much torque you need. Finally, you can test different settings and see which one works best. Always remember to be safe while testing!”}},{“@type”: “Question”,”name”: “What Are The Consequences Of Inadequate Torque On The Cutting Tool During The Lathe Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cutting tool doesn’t have enough torque, it won’t work well. The tool might slip or get stuck. This can cause bad cuts on the material you’re shaping. It might even break the tool or make it wear out faster. Overall, you’ll end up with a messy job and wasted time.”}},{“@type”: “Question”,”name”: “How Can You Adjust The Speed And Torque Settings On A Metal Lathe To Accommodate Various Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the speed on a metal lathe, you can turn a knob or change a switch. Higher speed helps you cut threads faster, while lower speed gives you more control. To change torque, or turning power, you might need to switch gears or settings. These changes help us make different types of threads more easily. Always check the manual for your specific lathe for exact instructions.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken To Prevent Torque-Related Issues While Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stay safe while using a metal lathe, always wear safety glasses. Make sure your hair and clothes are away from the machine. Check the tools and parts before starting to ensure they are clean and secure. Use both hands to hold the workpiece steady. Finally, keep a safe distance from moving parts.”}}]}