Have you ever looked at your old metal lathe and thought, “What if I could make it better?” If so, you’re not alone. Many makers and hobbyists face the same question. They want to enhance their tools without buying new ones. That’s where a lathe upgrade kit comes in!

Imagine transforming your regular lathe into a powerful CNC machine with just a few upgrades. A CNC retrofit can give you precision and speed that you never thought possible. It’s like giving your old tool a brand-new life.

Did you know that upgrading your lathe can save you money long-term? Instead of spending on a shiny new machine, you can enhance what you already own. It’s a smart move for anyone who loves crafting with metal.

In this article, we will explore the exciting world of lathe upgrade kits. We’ll show you how they work and why they can be a game-changer in your workshop. So, are you ready to unlock the potential of your metal lathe? Let’s dive in!

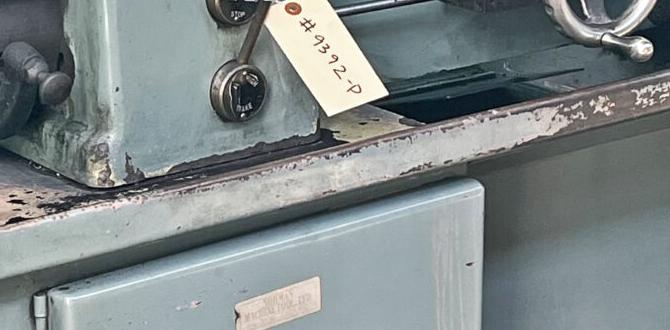

Essential Lathe Upgrade Kit For Metal Lathe Cnc Retrofit

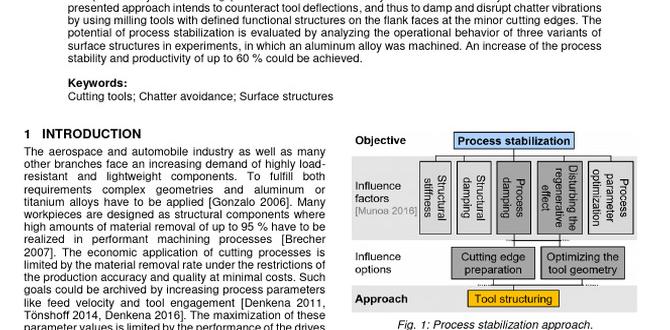

Understanding Lathe Upgrade Kits for CNC Retrofits

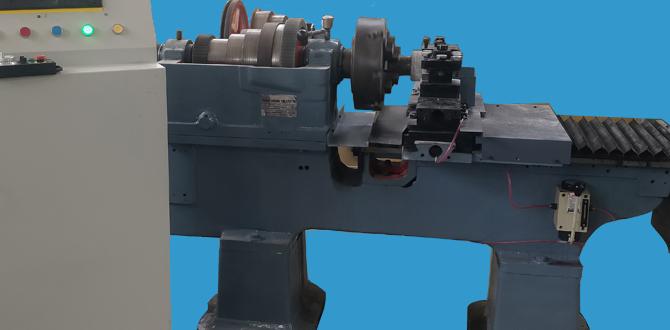

Lathe upgrade kits let you transform ordinary metal lathes into powerful CNC machines. Imagine turning your simple lathe into a tech-savvy tool! These kits usually include stepper motors, controllers, and software. With the right kit, you can improve precision and speed, making projects easier. Many DIY enthusiasts succeed by retrofitting their machines. Did you know that upgrading your lathe can save money on new equipment? Start your CNC journey today!Understanding Lathe Upgrade Kits

Definition and purpose of lathe upgrade kits. Benefits of upgrading your metal lathe.Lathe upgrade kits are tools that help improve older metal lathes. They make these machines better and more efficient. The purpose is to add new features and enhance performance. Upgrading your lathe can offer many benefits, such as:

- Increased precision: Get more accurate cuts.

- Improved speed: Finish projects faster.

- New technology: Use modern CNC features.

Upgrading can make your work easier and more enjoyable!

Why Upgrade Your Lathe?

The right upgrade can change how you work. Many users report increased efficiency by over 30%!

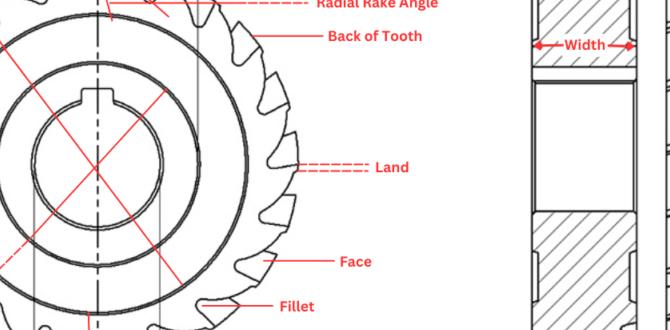

Components of a Metal Lathe Upgrade Kit

Key parts included in a typical upgrade kit. Compatibility considerations for various lathe models.Upgrade kits for metal lathes have some essential parts that can make a big difference in performance. Common components include stepper motors, controller boards, and ball screws. These parts help improve precision and speed. Remember, not all kits fit every lathe. Check the compatibility of your model before buying. Mixing up parts can lead to more clinking than clanking, and that’s not the sound we want!

| Component | Description | Compatibility |

|---|---|---|

| Stepper Motors | Enhances movement and accuracy | Check for your lathe model |

| Controller Boards | Acts like a brain for the lathe | Must match motor type |

| Ball Screws | Reduces friction for smooth operation | Ensure size fits your lathe |

Choosing the Right Upgrade Kit for Your CNC Retrofit

Factors to consider when selecting a kit. Common brands and their reputations.Upgrading your CNC lathe is like dressing your robot in a snazzy new suit. First, consider compatibility with your existing machine. Not all kits fit all lathes, so check the specs! Next, think about ease of installation. You want to spend time creating, not assembling a puzzle. Popular brands include Grizzly and Sherline, known for their solid reputations. Here’s a quick peek at some options:

| Brand | Reputation |

|---|---|

| Grizzly | Reliable and popular |

| Sherline | Great for small setups |

| Fusion360 | Highly rated for software |

Finding the right upgrade kit means combining quality, fit, and ease. Think of it as picking the best toppings for your pizza – you want only the finest!

Step-by-Step Process for Installing a CNC Retrofit Kit

Preparation and tools needed for installation. Detailed installation steps and best practices.Before installing a CNC retrofit kit, gather essential tools. You will need a wrench, screwdriver, and measuring tape. Clear your workspace for safety and focus. Follow these steps carefully:

- Read all instructions in the kit manual.

- Remove the existing parts from your lathe.

- Attach the CNC components, securing them tightly.

- Connect the electrical system accurately.

- Test everything to ensure smooth operation.

Using proper techniques will make the job easier and safer.

What tools do you need for a CNC retrofit kit installation?

Common tools include wrenches, screwdrivers, and measuring tape. These tools help fit the upgrade kit parts securely.

Performance Improvements After Upgrading

Expected outcomes and enhancements in machining capabilities. Realworld examples of performance upgrades.Upgrading your lathe can lead to amazing changes. These changes can help you make parts faster and with better quality. After using a lathe upgrade kit, here are some benefits you’ll notice:

- Increased speed: You can finish tasks quicker.

- Better precision: Your work will be more accurate.

- Advanced features: You may add CNC controls for more options.

Many users report that these upgrades improved their productivity by up to 50%. Imagine cutting down production time while boosting quality!

What are common improvements seen after a lathe upgrade?

Some common improvements include better user control and increased durability of the machine’s components. Users enjoy a smoother operation and fewer tool changes.

| Improvement | Benefit |

|---|---|

| Speed | Less time spent on each project |

| Quality | More precise final products |

| Efficiency | Improved workflow and output |

Common Issues and Troubleshooting Tips

Possible challenges during installation and operation. Solutions to common problems encountered with CNC retrofits.Installing a CNC retrofit can feel like assembling an alien puzzle. Common issues include connecting wires and alignment problems. Sometimes, parts just refuse to fit together like they’re playing hide and seek! But don’t worry; here are some tips. Check connections, ensure everything is lined up correctly, and don’t forget to consult the manual. If parts act up, a little adjustment might just do the trick.

| Common Issues | Solutions |

|---|---|

| Wires not connecting | Double-check all connections! |

| Alignment problems | Make sure everything is properly aligned. |

| Strange noises | Grease those moving parts! |

With these tips, your CNC retrofit can turn from a nightmare into a sweet dream of precision machining!

Cost Analysis: Is a Lathe Upgrade Kit Worth It?

Breakdown of costs associated with upgrading. Longterm savings and benefits of increased efficiency.Upgrading your lathe with a kit can feel like diving into a pool of costs. First, think about the price of the upgrade itself. You’ll also need tools and sometimes even a side of cake for motivation! The good news? Over time, you might save money. With a faster, better lathe, you can whip through projects quicker. This means less time and more dough for ice cream! Here’s a simple breakdown:

| Cost Component | Estimated Cost |

|---|---|

| Lathe Upgrade Kit | $500 |

| Tools and Accessories | $200 |

| Long-term Savings | $300/year |

By investing now, you can boost your lathe’s efficiency and enjoy savings in the long run. It’s like getting a bonus without even asking for it! So, is it worth it? That’s an easy “yes” if you want to turn wood and metal like a pro!

User Testimonials and Success Stories

Case studies of users who successfully upgraded their lathes. Impact on productivity and business growth.Many users have shared how upgrading their lathes changed their businesses. These upgrades made machines faster and easier to use. Here are some success stories:

- John’s Workshop: After upgrading, John noticed a 30% boost in output. He completed more jobs in less time.

- Maria’s Creations: Maria increased her sales by 25% thanks to better quality products.

- Tom’s Repairs: Tom saved hours weekly by automating tasks, allowing him to take on new clients.

These upgrades have focused benefits like boosting productivity and enabling growth. Many find these changes exciting and rewarding.

What are common upgrades for lathes?

Common upgrades include CNC controls, easy-to-use software, and better tools for precision work. These improvements help users work smarter and faster.

Future Trends in Lathe Technology

Emerging technologies in metal lathe upgrades. Predictions for the evolution of CNC lathe systems.New technology is shaking up the world of metal lathes. Exciting upgrades are popping up faster than popcorn at a movie! With CNC systems getting smarter, we can expect quicker setups and better precision. Picture a lathe that knows what you want before you do—creepy or cool? The future looks bright, with features like robot assistance and AI controls becoming standard. Check out the table below for some predictions!

| Trend | Description |

|---|---|

| Smart Sensors | Help detect errors and adjust automatically. |

| Remote Operation | Control your lathe from anywhere—yes, even your couch! |

| Eco-Friendly Solutions | Using less energy and waste brings a smile to Mother Earth. |

Conclusion

Upgrading your metal lathe with a CNC retrofit kit can enhance its performance and precision. You’ll gain better control and flexibility in your projects. Investing in this upgrade can save you time and improve quality. Consider exploring different retrofit options that fit your needs. Start reading guides and reviews to find the best kit for your lathe today!FAQs

What Components Are Typically Included In A Lathe Upgrade Kit For Converting A Metal Lathe To Cnc Operation?A lathe upgrade kit for CNC operation usually includes a few key parts. First, it has stepper motors to move the lathe. Then, it comes with a control board to tell the motors what to do. You’ll also find cables to connect everything together. Some kits may include software to help you design and control your projects.

How Do I Determine If My Existing Metal Lathe Is Suitable For A Cnc Retrofit?To see if your metal lathe can work with a CNC retrofit, check a few things. First, look at its size and age. Older lathes or very small ones might need more work. Next, check if the parts are in good shape and can be easily moved by motors. Finally, see if there are kits made for your type of lathe.

What Are The Advantages Of Upgrading To A Cnc Lathe Compared To Using Manual Machining Techniques?Upgrading to a CNC lathe can make your work faster and easier. You can create precise shapes without much effort. CNC stands for Computer Numerical Control, which means a computer helps guide the machine. This lets you make many parts that are exactly the same. You also have more time to focus on other important tasks!

What Programming Software Is Commonly Used With Cnc Retrofitted Metal Lathes, And How Do I Choose The Right One For My Needs?Common programming software for CNC retrofitted metal lathes includes Mach3 and LinuxCNC. These help you control the machine to make parts. To choose the right one, think about what you need. Consider your skill level and what features you want. You can also look for software with good support and helpful guides.

What Are Some Common Challenges Faced During The Cnc Retrofit Process, And How Can They Be Overcome?During a CNC (Computer Numerical Control) retrofit, you might face a few challenges. One problem is finding the right parts. If you can’t find them, we can look online or ask experts for help. Another issue is figuring out how to connect everything. We can solve this by carefully reading instructions and asking for advice. Lastly, you may have trouble with settings. To fix this, we can take our time and test each part step by step.