Upgrading a metal lathe can be a fun project. Have you ever thought about how a simple upgrade can make your tools work better? Many people underestimate the power of a lathe upgrade kit. It can change your metal lathe from good to great.

One crucial part of this upgrade is understanding the wiring. A clear wiring diagram can help you avoid mistakes during installation. Imagine being able to create precise parts without frustration! Knowing how to properly wire your lathe is key to success.

Did you know some metal lathe users say that a proper upgrade turned their hobby into a small business? It’s true! With the right lathe upgrade kit and wiring understood, you can unlock your full potential. Get excited about what you can create!

Let’s dive deeper into the details of the lathe upgrade kit and how to make your metal lathe work its best. Start your upgrade journey today!

Lathe Upgrade Kit: Metal Lathe Wiring Diagram Guide

Lathe Upgrade Kit Metal Lathe Wiring Diagram

With a lathe upgrade kit, you can enhance your metal lathe’s performance. The wiring diagram is crucial for proper installation. It helps you understand where each wire goes, ensuring safety and efficiency. Did you know that a well-upgraded lathe can cut down on production time? This kit can also save you money by improving your machine’s lifespan. Whether you’re a beginner or seasoned pro, this guide can empower your skills and creativity!Understanding Lathe Upgrade Kits

Definition of lathe upgrade kits and their purpose. Benefits of upgrading your metal lathe.Lathe upgrade kits improve the performance of your metal lathe. These kits add features or replace parts, making your lathe stronger and more efficient. Upgrading can lead to better accuracy and faster work time.

- Enhanced precision: Get more accurate cuts.

- Increased speed: Work faster on projects.

- Better tools: Use advanced equipment for quality results.

With these benefits, upgrading your lathe is a smart move for any builder or hobbyist.

What is a lathe upgrade kit?

A lathe upgrade kit is a set of tools and parts that enhances the functions of a metal lathe. It helps improve its performance and capability.

Why upgrade a metal lathe?

Upgrading a metal lathe boosts efficiency and quality of work. It simplifies tasks and saves time, making it worthwhile for users.

Choosing the Right Upgrade Kit for Your Lathe

Factors to consider when selecting an upgrade kit. Compatibility with various metal lathe models.Upgrading your lathe can feel like shopping for a new toy, but it’s crucial to choose wisely. First, think about compatibility. Not every upgrade kit fits all lathe models, so double-check before you buy. It’s like trying to fit a square peg in a round hole—just won’t work! Also, consider the features you need. Some upgrades offer fancy extras that might distract you. Keep it simple, make sure it suits your needs, and you’ll be turning masterpieces in no time!

| Factor | Importance |

|---|---|

| Compatibility | Essential |

| Features | Helpful for performance |

| Price | Budget-friendly options available |

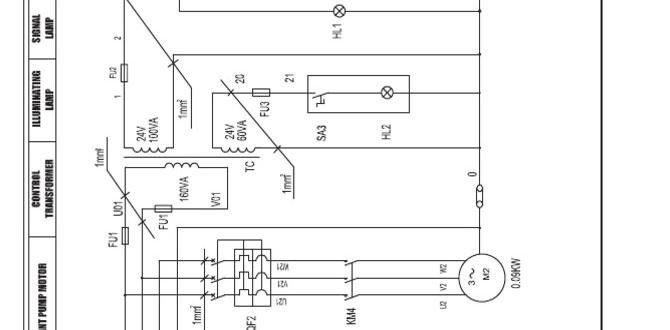

Detailed Wiring Diagrams for Metal Lathes

Explanation of basic wiring diagram components. Stepbystep guide to reading and understanding wiring diagrams.Understanding wiring diagrams is key for metal lathes. These diagrams show how different parts connect. Key components include wires, switches, and motors. Each symbol represents a part. To read a wiring diagram, follow these steps:

- Identify symbols.

- Trace the wires.

- Look for connections.

This way, you can easily understand how your lathe works. A simple wiring diagram can turn complex tasks into easy ones!

What are common components in a wiring diagram?

Common components include power sources, connectors, and motors. Each plays a different role in making the lathe function smoothly.

Installation Process of Upgrade Kits

Tools and materials needed for installation. Stepbystep instructions for installing the upgrade kit.To get your lathe upgrade kit ready, gather a few handy tools and materials first. You’ll need a wrench, screwdriver, and some colorful wires that might just brighten your day! Now, here’s a quick step-by-step guide:

| Steps | Description |

|---|---|

| 1. Turn off the power | Safety first! Unplug your lathe before starting. |

| 2. Remove old parts | Carefully take out the old kit. No wrestling required! |

| 3. Install the new kit | Follow the instructions that come with it. Let’s make it fit! |

| 4. Connect wires | Attach wires based on the diagram. Blue to blue, red to red! |

| 5. Power on | Time for the big reveal! Plug it back and test it out. |

Follow these steps, and soon you’ll be a lathe master, making all sorts of cool things! If you mix up a wire, you might just create a light show instead.

Troubleshooting Common Issues During Installation

Common problems encountered and their solutions. Safety tips when working with electrical components.Installing a lathe upgrade kit can be fun, but it may also lead to some head-scratching moments. One common issue is poor connections. Make sure all wires are snug and happy. If the machine won’t start, check if you’ve flipped the switch to “on.” Safety tip: always unplug your lathe before tinkering with wires—no one wants a shocking surprise!

If the lathe hums but doesn’t spin, check your wiring diagram. Wrong connections can turn your lathe into a rather fancy paperweight! Here’s a handy table to help:

| Issue | Solution |

|---|---|

| Poor connections | Check all wire connections. |

| Won’t power on | Ensure it’s plugged in and switched on. |

| Hums but doesn’t spin | Verify wiring against the diagram. |

For extra points, remember to wear gloves and goggles while working. Electricity is exciting, but it’s wise to keep your fingers safe. Happy upgrading!

Maintenance Tips for Upgraded Metal Lathes

Regular maintenance practices to ensure longevity. Importance of proper wiring and connection checks.To keep your upgraded metal lathe running smoothly, regular maintenance is a must. Think of it like brushing your teeth; a little effort goes a long way! Check the wiring and connections often. Loose wires are like pesky socks on laundry day, always causing trouble. Proper connections can save you time and money!

| Maintenance Task | Frequency |

|---|---|

| Inspect wiring | Every week |

| Clean machine | Daily |

| Lubricate moving parts | Monthly |

Remember, a well-maintained lathe not only lasts longer but also works better. Happy lathing!

Case Studies: Success Stories of Lathe Upgrades

Reallife examples of lathe upgrades and their results. Lessons learned from different users’ experiences.Many users have turned their aging lathes into powerful tools. For instance, one hobbyist upgraded his old lathe and saw a 50% boost in efficiency. Moral of the story? Don’t underestimate a vintage machine! Some found that better wiring led to smoother operations. Others learned the hard way: always read the wiring diagram first! Here’s a fun fact: one user’s lathe turned out to be a home for a small family of mice! It’s always about the adventure and the upgrades!

| User | Upgrade | Result |

|---|---|---|

| Mike | Wiring Kit | 50% more efficiency |

| Sara | Speed Controller | Smoother cuts |

| Tom | Lathe Upgrade Kit | Newfound joy! |

Expert Tips and Recommendations

Additional tips for maximizing the benefits of upgrade kits. Recommendations for reputable brands and suppliers.To get the most from your lathe upgrade kit, consider these tips. First, review the wiring diagram carefully. Understand each connection and part. That helps prevent mistakes. Choose high-quality tools to ensure smooth operation. Always ask for help if you are unsure about installation.

For reliable brands, look for:

- Grizzly Industrial – Offers a range of upgrade kits.

- Jet Tools – Known for durability and quality.

- Baileigh Industrial – Provides detailed service support.

These brands are popular among hobbyists and professionals. They can help enhance your metal working experience.

What are some tips for using an upgrade kit?

Read the instructions first. Make sure you have all the parts. Test the lathe after installation to ensure it works well.Conclusion

In conclusion, a lathe upgrade kit can greatly improve your metal lathe’s performance. Understanding the wiring diagram is crucial for safe and effective upgrades. With the right kit, you can enhance precision and efficiency. We encourage you to explore different kits and diagrams online. Remember, a well-upgraded lathe can help you create amazing projects more easily!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Upgrade Kit For Metal Lathe Wiring Diagrams:Sure! Here are five questions you might ask about a lathe upgrade kit for wiring diagrams: 1. What is a lathe upgrade kit? 2. How do I use the wiring diagram? 3. Why should I upgrade my lathe? 4. What tools do I need for the upgrade? 5. Where can I find the wiring diagram? If you want to know more about any of these, just ask!

Sure! Please provide the question you would like me to answer.

What Components Are Typically Included In A Metal Lathe Upgrade Kit That May Require A Wiring Diagram?A metal lathe upgrade kit usually has parts like a new motor, control panel, and wiring connectors. You might also get sensors and switches to help with control. Each of these parts needs to connect properly, so a wiring diagram shows you how to do it. This way, you can make sure everything works safely and correctly.

How Do You Interpret The Wiring Diagram For Installing An Upgrade Kit On A Specific Metal Lathe Model?To read the wiring diagram, first look at the labels. They show where each wire goes. Use the color codes to match wires correctly. Follow the diagram step by step, and double-check your work. If you get stuck, ask someone for help!

What Safety Precautions Should Be Taken When Working With Electrical Wiring On A Metal Lathe Upgrade?When working with electrical wiring, always unplug the machine first. Wear rubber gloves to protect your hands. Use insulated tools so you don’t get shocked. Keep the area dry and clean to avoid slips. Finally, ask an adult for help if you’re unsure about something.

Are There Common Troubleshooting Steps To Follow If The Metal Lathe Does Not Operate Correctly After Installing The Upgrade Kit?If your metal lathe isn’t working right after the upgrade, first, check the power source. Make sure it’s plugged in and the switch is on. Next, look closely at the connections. Are all the wires connected tightly? Lastly, consult the upgrade guide for any steps you might have missed. If it still doesn’t work, ask someone for help.

What Resources Or Manuals Are Available To Help Guide Users Through The Wiring Process Of A Metal Lathe Upgrade Kit?To help you with your metal lathe upgrade kit, many resources are available. You can start by checking the instruction manual that comes with the kit. It usually has simple steps and pictures. There are also online videos that show you how to wire it all together. You can find helpful guides on websites made for metalworking too.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Upgrade Kit For Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about a lathe upgrade kit for wiring diagrams: 1. What is a lathe upgrade kit? 2. How do I use the wiring diagram? 3. Why should I upgrade my lathe? 4. What tools do I need for the upgrade? 5. Where can I find the wiring diagram? If you want to know more about any of these, just ask!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Components Are Typically Included In A Metal Lathe Upgrade Kit That May Require A Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe upgrade kit usually has parts like a new motor, control panel, and wiring connectors. You might also get sensors and switches to help with control. Each of these parts needs to connect properly, so a wiring diagram shows you how to do it. This way, you can make sure everything works safely and correctly.”}},{“@type”: “Question”,”name”: “How Do You Interpret The Wiring Diagram For Installing An Upgrade Kit On A Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To read the wiring diagram, first look at the labels. They show where each wire goes. Use the color codes to match wires correctly. Follow the diagram step by step, and double-check your work. If you get stuck, ask someone for help!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With Electrical Wiring On A Metal Lathe Upgrade?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with electrical wiring, always unplug the machine first. Wear rubber gloves to protect your hands. Use insulated tools so you don’t get shocked. Keep the area dry and clean to avoid slips. Finally, ask an adult for help if you’re unsure about something.”}},{“@type”: “Question”,”name”: “Are There Common Troubleshooting Steps To Follow If The Metal Lathe Does Not Operate Correctly After Installing The Upgrade Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe isn’t working right after the upgrade, first, check the power source. Make sure it’s plugged in and the switch is on. Next, look closely at the connections. Are all the wires connected tightly? Lastly, consult the upgrade guide for any steps you might have missed. If it still doesn’t work, ask someone for help.”}},{“@type”: “Question”,”name”: “What Resources Or Manuals Are Available To Help Guide Users Through The Wiring Process Of A Metal Lathe Upgrade Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help you with your metal lathe upgrade kit, many resources are available. You can start by checking the instruction manual that comes with the kit. It usually has simple steps and pictures. There are also online videos that show you how to wire it all together. You can find helpful guides on websites made for metalworking too.”}}]}