Have you ever used a lathe and felt it shake? That vibration can cause big problems. It makes your metal lathe less accurate and can ruin your project. Imagine spending hours working only to get a wobbly finish!

In the world of metalworking, controlling lathe vibration is a must. Most people don’t know that even small changes can make a huge difference. For example, did you know that the position of your tools can affect how much your lathe vibrates? It’s true!

In this article, we will explore simple ways to reduce lathe vibration. We’ll share tips that anyone can follow. You’ll learn how to help your metal lathe run smoother. Let’s dive in and make your projects easier and more fun!

Lathe Vibration Reduction For Metal Lathe Efficiency

Lathe Vibration Reduction in Metal Lathes

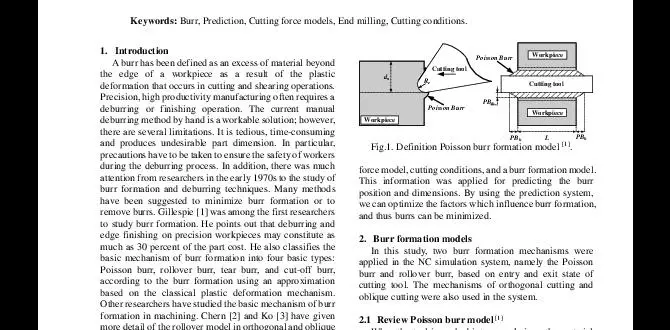

Did you know that excessive vibration in metal lathes can lead to poor finishes and shortened tool life? Reducing lathe vibration is crucial for high-quality machining. Simple strategies include enhancing machine rigidity and isolating vibrations with pads. Adding damping materials is also effective. Investing time and resources in vibration reduction not only improves the finished product but boosts efficiency. A quiet workspace can be a game changer. Are you ready to make your metal lathe work better?Understanding Lathe Vibration

Definition of lathe vibration and its causes. Impact of vibration on machining quality and tool life.Lathe vibration is when the machine shakes during work. It happens for many reasons, like uneven surfaces or poor tool setup. This shaking can ruin projects and make tools wear out faster. Think of it like this: if your car vibrates while driving, it’s not a smooth ride! Vibration messes with machining quality and can turn your metal masterpiece into a wobbly disaster.

| Causes of Lathe Vibration | Impact on Machining |

|---|---|

| Uneven workpieces | Poor surface finish |

| Loose parts | Shorter tool life |

| Poor setup | Increased wear on machinery |

Identifying Sources of Vibration in Metal Lathes

Common mechanical sources of vibration. External factors contributing to lathe vibration.Vibration in metal lathes can come from many places. Some common sources include:

- Loose parts that rattle while the lathe spins.

- Unbalanced tools that can shake the machine.

- Wear and tear on bearings that causes extra movement.

External factors also add to lathe vibration. These can be:

- Floor vibrations from heavy machines nearby.

- Temperature changes that affect metal and parts.

- Air currents that can knock tools out of balance.

Identifying these sources can help reduce vibration. This leads to better work quality and longer tool life.

What are the main sources of vibration in metal lathes?

Main sources include loose parts, unbalanced tools, and worn bearings.

What external factors contribute to lathe vibration?

External factors include nearby machine vibrations, temperature changes, and air currents.

Materials and Design Considerations for Minimizing Vibration

The role of material stiffness and damping properties. Optimizing lathe design for stability.Using the right materials can turn your metal lathe into a smooth operator. Strong materials add stiffness, which helps keep vibrations at bay. Think of it like a big, sturdy tree resisting wind. Adding dampers can soak up those annoying shakes, similar to how a sponge absorbs water. Smart design choices, like a wider base and balanced parts, create stability. It’s like building a solid chair: the more sturdy it is, the less it wobbles. A well-designed lathe means smoother cuts and happy metal!

| Material | Stiffness | Damping Properties |

|---|---|---|

| Cast Iron | High | Good |

| Steel | Very High | Fair |

| Aluminum | Medium | Poor |

Balancing and Alignment Techniques

Importance of proper balancing of rotating components. Steps to ensure accurate alignment of the lathe.Properly balancing rotating parts is essential for a metal lathe. It helps to reduce vibration, which can damage your equipment and affect the quality of your work. Here are steps to ensure accurate alignment of your lathe:

- Check for any wear or damage.

- Use a dial indicator for precise measurements.

- Adjust the lathe bed for level placement.

- Tighten all screws and bolts properly.

Following these steps improves performance and extends the life of your lathe.

Why is balancing important for a lathe?

Balancing reduces wear and tear, enhancing the lathe’s lifespan and performance.

Operational Practices to Reduce Vibration

Adjusting cutting parameters and tool selection. Techniques for maintaining consistent workholding.Reducing vibration on a lathe is simple with the right practices. First, adjusting cutting parameters can make a big difference. Use the right speed and feed rates to keep things smooth. Picking the right tool is also key. A good tool can help avoid chatter, which sounds like a cat stuck in a blender!

Consistent workholding is equally important. Always ensure your material is tightly secured. If it’s loose, it might dance like it’s at a party instead of staying still! Here are some quick tips:

| Technique | Tip |

|---|---|

| Adjust Speed | Find the sweet spot for your material. |

| Tool Selection | Choose tools designed for vibration reduction. |

| Workholding | Use clamps and chucks to secure materials. |

With these practices, you can strike the perfect balance and keep your lathe running smoothly!

Regular Maintenance and Monitoring Strategies

Importance of routine inspections and maintenance for vibration management. Utilizing technology for vibration monitoring and analysis.Keeping machines like metal lathes in good shape is crucial. Regular checks help spot problems early. This can reduce vibration and improve performance. Using technology is smart too. Instruments can measure vibrations and provide data for better analysis. This way, operators can make informed decisions and avoid costly breakdowns.

Why is Routine Maintenance Important?

Routine maintenance can reduce surprises and keep machines running smoothly. Regular inspections can spot tiny issues before they turn big. Keeping up with these practices helps save both time and money.

Here are some quick tips:

- Check all parts regularly.

- Use vibration monitoring tools.

- Keep clean and lubricated.

They say, “An ounce of prevention is worth a pound of cure.” This means a little care goes a long way. Regular monitoring leads to long-lasting machines!

Case Studies: Successful Vibration Reduction Implementations

Examples of companies that effectively reduced lathe vibration. Lessons learned and best practices from realworld applications.Many companies have tackled lathe vibrations with real success, and their stories are pretty inspiring. For example, Machine Works Inc. used special dampeners and saw a 30% reduction in vibrations! Now that’s smoother than a buttered slide! Another company, Precision Tools Co., revamped their lathe setup, learning that spacing and weight matter. They practically turned their machines into vibrationless wonders. Best practices? Always check your tools, and don’t forget to laugh at vibrations—they hate the competition!

| Company | Vibration Reduction (%) | Key Takeaway |

|---|---|---|

| Machine Works Inc. | 30% | Use dampeners for smoother operations. |

| Precision Tools Co. | 25% | Space and weight adjustments are crucial. |

Conclusion

In conclusion, reducing lathe vibration is essential for better metalworking results. You can improve accuracy and finish quality by stabilizing your machinery. Regular maintenance and proper setup also help. To learn more, explore guides on lathe operation and vibration control. Implement these tips, and you’ll see a difference in your projects. Happy crafting!FAQs

What Are The Common Causes Of Vibrations In Metal Lathes, And How Can They Be Identified?Vibrations in metal lathes can happen for a few reasons. First, the machine might not be set up correctly. Second, the cutting tools might be dull or broken. Third, the workpiece might not be held tightly enough. We can find these problems by checking the setup, looking at the tools, and making sure everything is tight.

How Can Proper Alignment And Leveling Of A Metal Lathe Help In Reducing Vibrations During Operation?When you set up a metal lathe, it needs to be straight and flat. Proper alignment means all parts fit together well. This helps keep the machine steady and balanced. If the lathe is not level, it can wobble and make more noise. By making sure it’s aligned and level, we can reduce those vibrations while we work.

What Role Do Vibration Dampening Materials And Systems Play In Enhancing The Stability Of A Metal Lathe?Vibration dampening materials help stop shaking and noise in a metal lathe. When we reduce vibrations, the lathe works better and stays steady. This makes it easier to cut metal accurately. Strong and smooth cuts lead to better projects. Overall, these materials make the machine safer and more useful.

How Can Spindle Speed And Feed Rate Adjustments Affect Vibration Levels In Lathe Machining?When we change the spindle speed, which is how fast the lathe spins, it can make a big difference. If the speed is too high or too low, it might cause wobbling or vibrations. The feed rate, or how quickly the machine moves, also affects this. If we adjust these settings carefully, we can make the machine run smoother and reduce shaking. This helps us work better and make better parts.

What Are Some Effective Techniques Or Tools For Measuring And Monitoring Vibrations In Metal Lathe Operations?To measure vibrations in metal lathe operations, you can use a tool called a vibration meter. It helps you see how much the lathe shakes while it works. You can also use sensors that attach to the machine. These sensors send information to a computer. By checking this data, you can find and fix problems before they get bigger.