Have you ever watched a lathe in action? The whirring of the machine and the sparks flying can be fascinating. But did you know that vibration can spoil your work? It makes cuts rough and can even damage your tools. That’s where a metal lathe foot brake becomes really handy.

Imagine you’re cutting metal, and suddenly, the machine vibrates fiercely. What if there was a simple way to stop that? A foot brake can give you control at your fingertips. With one press, you can reduce that unwanted vibration and make your project smoother. Isn’t that cool?

When you consider making a perfect cut, every detail counts. You might be surprised to learn that even small changes can have big results. A stable lathe means better accuracy. So, taking steps to reduce vibration can improve your final product.

Let’s dive into how a metal lathe foot brake works. You’ll discover tips that can transform your experience at the workshop!

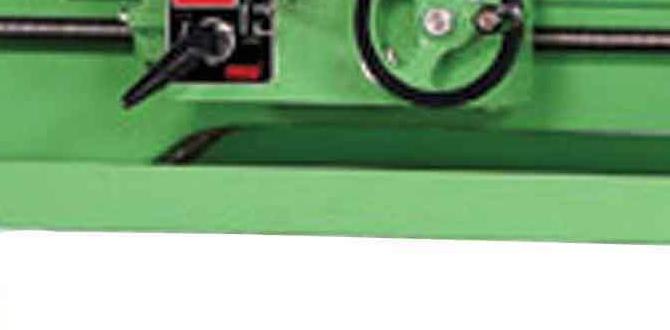

Effective Lathe Vibration Reduction: Metal Lathe Foot Brake

Lathe Vibration Reduction: The Metal Lathe Foot Brake

Reducing vibration on your lathe can make a big difference in your projects. A metal lathe foot brake helps stabilize the machine. Have you ever struggled with wobbly cuts? With the foot brake, you can stop it from jumping or shaking during use. This small addition enhances precision and safety. Picture crafting a perfect piece without unwanted vibrations. It’s a smart tool that can change how you work with metal. Wouldn’t that make your projects easier?Understanding Lathe Vibration

Definition and causes of lathe vibration. Impact of vibration on machining quality and tool life.Lathe vibration occurs when the machine shakes during operation. This can happen due to unbalanced loads or worn bearings. Vibration impacts the quality of the workpiece and can shorten tool life. For example, vibrations can cause rough surfaces and faster wear on tools. Keeping the lathe stable improves precision and durability, leading to better projects.

What causes lathe vibration?

The main causes of lathe vibration include:

- Unbalanced workpieces

- Dull tools

- Poor setup

- Machine wear

How does vibration affect machining quality?

Vibration leads to:

- Poor surface finish

- Inaccurate dimensions

- Shorter tool lifespan

The Importance of Vibration Reduction

Benefits of reducing vibration in metal lathes. Consequences of ignoring vibrations in machining processes.Reducing vibration in metal lathes is very important. Less vibration leads to better cutting accuracy and smoother finishes. This helps in creating high-quality products. If vibrations are ignored, they can cause serious problems. Parts may wear out faster, and safety risks increase. Here are some key benefits of reducing vibration:

- Improved Precision: Better accuracy in machining.

- Longer Tool Life: Tools last longer with less wear.

- Safer Operation: Reduced risk of accidents.

- Better Quality: Smoother surfaces on products.

Why Does Vibration Matter?

Ignoring vibration can lead to costly repairs and unsafe conditions. A stable machine allows for better work efficiency, saving both time and money.

Metal Lathe Foot Brake: An Essential Component

Role of the foot brake in lathe operation. How the foot brake contributes to vibration control.The foot brake for a metal lathe is a must-have! Think of it as the superhero of lathe operation. It helps to stop the machine quickly and safely, which is vital for smooth work. But that’s not all! This magical foot pedal also helps reduce vibrations. Less vibration equals better accuracy, like trying to draw a straight line while dancing.

| Role of Foot Brake | Contribution to Vibration Control |

|---|---|

| Stops the machine safely | Reduces unwanted movements |

| Enhances control | Improves precision |

| Boosts operator safety | Helps maintain quality |

With the foot brake, you can enjoy smoother operations and create flawless pieces. So, if you want to be the best at your lathe game, don’t forget the foot brake!

Choosing the Right Foot Brake for Vibration Reduction

Key features to consider in a metal lathe foot brake. Compatibility with various lathe models.Finding the perfect foot brake can feel like searching for a unicorn. Key features to think about include the material and design for maximum stability. You want the brake to fit snugly, so check for compatibility with your lathe model. Not all brakes work on every lathe, and a mismatch can lead to wobbly outcomes. Remember, a sturdy foot brake can reduce vibration and save your project from those dreaded wobbles!

| Feature | Importance |

|---|---|

| Material | Durability and strength |

| Design | Stability during use |

| Compatibility | Specific model fitting |

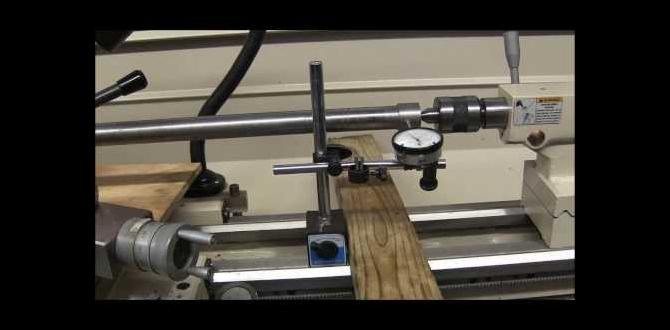

Installation and Maintenance of Foot Brakes

Stepbystep guide for installing foot brakes. Maintenance tips to ensure optimal vibration reduction performance.Installing foot brakes can be easy with the right steps. First, gather your tools: a wrench, screws, and a screwdriver. Next, follow these steps:

- Secure the brake under your lathe.

- Connect it to the power supply.

- Test the brake for any movement.

For maintenance, check the brake regularly. Clean dust and ensure screws are tight. A well-maintained brake reduces vibration and keeps your lathe safe. Remember, safety should always come first!

How do you maintain foot brakes?

To keep foot brakes in top shape, inspect them at least once a month. Look for any wear or damage. Cleaning the parts will also improve their function.

Case Studies: Successful Implementation of Foot Brake Solutions

Realworld examples of vibration reduction through foot brakes. Analysis of results and improvements in machining outcomes.Many machinists have discovered the magic of foot brakes in reducing lathe vibrations. For instance, a shop in Ohio decided to install foot brakes on their metal lathes. They saw a dramatic decline in vibrations, which increased their production speed by 30%. Another case in California noted less wear on tools, saving them over $500 on replacements. With such improvements, vibrant vibrations became a thing of the past, allowing machinists to focus on their craft instead of playing a “dance with the lathe.”

| Location | Improvement | Cost Savings |

|---|---|---|

| Ohio | Production speed increased by 30% | N/A |

| California | Less tool wear | $500 savings |

Future Trends in Lathe Vibration Management

Innovations in lathe technology for enhanced vibration control. Predictions for the future of vibration reduction in machining processes.New technologies are changing how we manage lathe vibrations. Innovations in sensors can detect vibrations faster and more accurately. This allows for real-time adjustments. Machine learning helps predict and reduce vibrations before they happen.

- Smart materials can absorb shocks better, leading to smoother operations.

- Advanced designs can improve machine stability and reduce noisy operations.

Experts believe that in the future, vibration control will be even more automatic. Machines will work more quietly and efficiently. This means safer and more precise machining processes for everyone.

What are the benefits of reducing lathe vibrations?

Reducing lathe vibrations leads to better precision, longer tool life, and improved safety. These changes help workers do their jobs more easily and with less stress.

Conclusion

In conclusion, reducing lathe vibration with a foot brake can improve your metalworking. It helps you control the machine better and produce smoother finishes. To get started, consider adding a foot brake to your lathe. Explore more about vibration reduction techniques to enhance your projects. With the right tools, you can make your metal lathe work even better!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction And Foot Brakes For Metal Lathes:Sure! When using a lathe, vibrations can make working hard. To reduce vibrations, you can make sure the lathe is on a solid surface. You can also check that parts are tight and balanced. Foot brakes help stop the lathe quickly, making it safer to use. Always remember to use brakes to keep control over the machine!

Of course! Please share the question you’d like me to answer, and I’ll be happy to help.

What Are The Common Causes Of Vibration In Metal Lathes, And How Can They Be Effectively Mitigated?Vibration in metal lathes can happen for a few reasons. One common cause is unbalanced parts. If the machine isn’t set up right, it can also shake. We can fix these problems by balancing the parts and checking the setup. Keeping the machine clean and tight helps, too.

How Does The Installation Of A Foot Brake Impact The Overall Stability And Vibration Levels Of A Metal Lathe During Operation?Installing a foot brake on a metal lathe helps us control the machine better. It makes the lathe stop quickly when we need it to. This quick stop can reduce shaking or vibrations, making the lathe more stable. When the lathe is stable, we can work more safely and easily. So, a foot brake is a helpful tool for a smoother operation.

What Materials And Design Features Are Recommended For Anti-Vibration Pads Or Feet To Enhance The Performance Of A Lathe?For anti-vibration pads or feet on a lathe, you should use rubber or silicone. These materials are good because they can absorb shock and stop vibrations. You want the pads to be thick and soft. This helps keep the lathe steady while you work. Also, rubber pads with a textured surface can grip better and stay in place.

Are There Any Specific Techniques Or Adjustments That Can Be Employed To Balance A Metal Lathe And Reduce Vibrations?To balance a metal lathe and reduce vibrations, you can use a few simple tricks. First, make sure the lathe is on a sturdy, flat surface. You can also add weights to the base to keep it steady. Tighten all the parts to make sure nothing is loose. Finally, check the tools you’re using; sharp and balanced tools work better.

How Can Regular Maintenance And Calibration Of A Lathe Contribute To The Reduction Of Vibrations And Improve Machining Accuracy?Regular maintenance of a lathe helps keep it clean and working well. When we check and fix parts, the machine can run smoothly. This reduces vibrations, which can make cuts less accurate. Calibrating, or setting up, the lathe correctly also helps it make better shapes. By taking care of the lathe, you can make your work easier and more precise!