Have you ever tried to make something on a metal lathe, only to find it vibrating like a washing machine? It’s frustrating, right? This vibration can mess up your project and ruin your hard work. But what if there was a way to stop that annoying shaking?

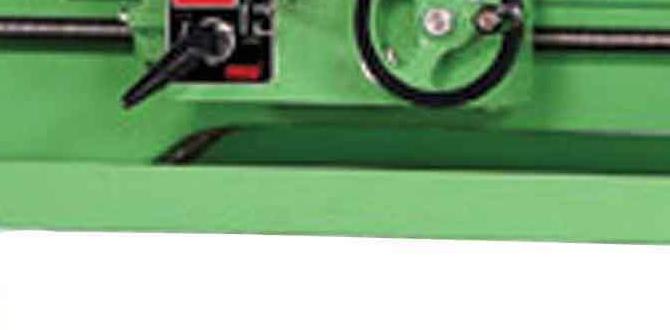

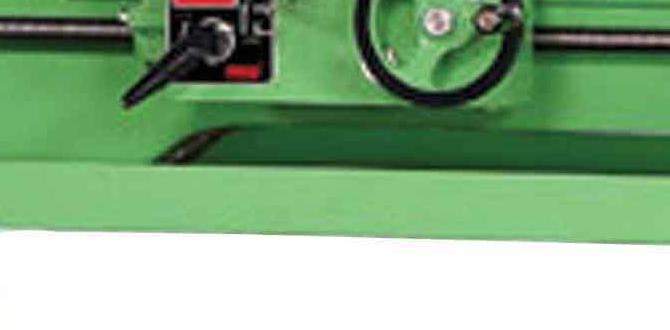

Many people don’t know that lathe vibration reduction is a key part of using a metal lathe effectively. By focusing on gear design and setup, you can keep your lathe steady. Imagine crafting a perfect part without all that jiggling!

In the world of metalworking, it’s surprising how much gear choices can impact performance. A simple change can lead to smoother operation and better results. This article will explore tips on reducing lathe vibration and improving your machining experience. It’s time to get your metal lathe working like a pro!

Lathe Vibration Reduction: Essential Metal Lathe Gear Solutions

Lathe Vibration Reduction: Key Gear Insights

Lathe vibration can cause major problems when working with metal. Did you know that reducing vibration helps improve accuracy? Using specialized gears in your metal lathe can make a big difference. These gears help stabilize the machine, leading to smoother operation. This can save you time and make your projects look better. Proper maintenance and gear selection are essential. Curious about how a small change can lead to great results? You might be amazed at the impact of reducing lathe vibration.Understanding Lathe Vibration

Definition and causes of lathe vibration. Importance of vibration reduction in metalworking.Lathe vibration is the shaking or wobbling that occurs while a lathe machine runs. This can happen for many reasons, like unbalanced parts or incorrect settings. It’s a bit like trying to keep a straight face when someone tells a bad joke! Reducing vibration is crucial in metalworking. It helps improve precision and product quality. Too much vibration can lead to mistakes, costing time and money. Imagine trying to dance on a wobbly floor—sounds like a disaster, right?

| Causes of Lathe Vibration | Effects of High Vibration |

|---|---|

| Unbalanced tools | Poor cut quality |

| Improper speeds | Increased wear and tear |

| Loose parts | Potential accidents |

The Impact of Vibration on Metal Lathe Performance

Effects on precision and surface finish. Implications for tool wear and lifespan.Vibration can really mess with a metal lathe’s performance. It can lead to poor precision and a rough surface finish. Imagine trying to draw a straight line while someone shakes your hand! This can cause tools to wear out faster, too, cutting the lifespan of your gear. To illustrate, check the table below:

| Effect of Vibration | Impact |

|---|---|

| Precision | Reduces accuracy |

| Surface Finish | Causes rough textures |

| Tool Wear | Increases wear and tear |

In short, tackling vibration is key to keeping your lathe happy and productive. Less wobble means better results, and better results mean more happy projects! Let’s keep that gear running smoothly!

Common Sources of Vibration in Metal Lathes

Mechanical sources: unbalanced parts and misalignments. External factors: environmental and operational influences.Metal lathes can dance and shake, but not in a good way! One main culprit is unbalanced parts. When some pieces are heavier, it can make the lathe wobble. Another reason is misalignments. If everything isn’t in line, the results can be shaky! External factors also play a role. Vibrations can come from the environment, like a noisy workshop, or from how the operator works. Even a clumsy puppy running by can cause a ruckus!

| Source | Effect |

|---|---|

| Unbalanced Parts | Wobbling |

| Misalignments | Shaking |

| Environmental Factors | Noisy operations |

| Operational Influences | Rough handling |

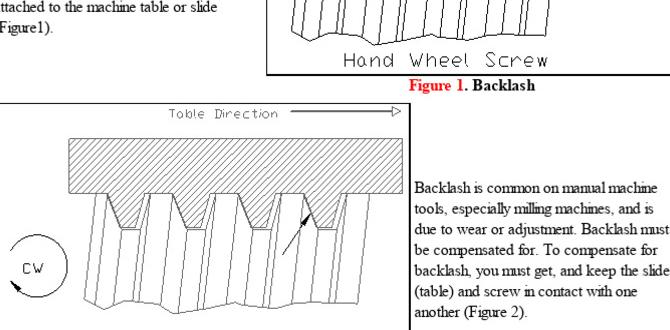

Effective Vibration Reduction Techniques

Mechanical modifications: balancing and dampening techniques. Operational adjustments: feed rate and cutting speed considerations.Vibration can be a sneaky troublemaker in metal lathes. Luckily, there are ways to tackle it. First up, mechanical modifications like balancing can help. Think of it like giving your lathe a spa day! Using dampening materials also keeps those unwanted shakes away. Next, for operational adjustments, tweaking the feed rate and cutting speed is key. Slow and steady wins the race, you know? Too fast can lead to chaos, so find a happy medium!

| Technique | Description |

|---|---|

| Balancing | Adjust weights on the machine parts to minimize vibration. |

| Dampening | Use materials that absorb vibration, like rubber or foam. |

| Feed Rate | Choose a slower feed rate to reduce vibrations during cutting. |

| Cutting Speed | Adjust speed for optimal cutting without excessive vibration. |

Advanced Technologies for Vibration Control

Use of sensors and monitoring systems. Innovative materials and designs for gear and lathe construction.Modern machines use smart sensors to detect vibration. These sensors alert operators about any issues quickly. This helps prevent damage and improves safety. Innovative materials are also important. New designs make gears and lathes stronger yet lighter. This reduces vibrations during use. With better designs, machines work more efficiently. They last longer and cost less to maintain.

How do sensors help reduce vibrations?

Sensors track machine movements, alerting users to any unusual patterns.Benefits of sensors:

- Quick problem detection

- Improved safety

- Efficiency in performance

New materials like composites make gears less heavy. They reduce fatigue and vibration. Advanced designs are stronger and keep parts in place. This helps machines perform better and makes work easier for everyone.

Maintenance Practices for Minimizing Lathe Vibration

Regular inspection protocols. Calibration and alignment checks.Keeping your lathe in tip-top shape is crucial for reducing vibrations. First, regular inspections are key. Check the machine often for any loose parts or unusual sounds. Think of it as checking your bicycle before a ride! Next, calibration and alignment checks are essential. A misaligned lathe can be like trying to play a guitar with a broken string. It just won’t work well! Remember, a little maintenance goes a long way in keeping your lathe humming along smoothly.

| Maintenance Task | Frequency |

|---|---|

| Inspect for loose parts | Weekly |

| Check alignment | Monthly |

| Lubricate moving parts | Every 500 hours |

Case Studies and Successful Implementations

Realworld examples of vibration reduction strategies. Lessons learned from different metalworking industries.Many factories have found ways to reduce vibration during metalworking. For example, a power tool company improved its machines and noticed less vibration. Workers reported better comfort and faster production. Another car manufacturer used better support for their lathes. This changed how smoothly the machines ran. The results showed significant improvements. Here are some key lessons:

- Regularly check and maintain tools.

- Use equipment with built-in vibration dampening.

- Train workers on proper techniques.

What are real-world examples of vibration reduction?

Some examples include improving machine parts and using special pads to support the tools. Each change helped make the machines work better and last longer.

Future Trends in Lathe Technology and Vibration Management

Emerging technologies in vibration analysis. Predictions for advancements in metal lathe design and efficiency.As lathe technology evolves, new tools and techniques pop up to tackle vibration issues like superheroes fighting evil. Emerging technologies in vibration analysis will soon help us spot these pesky vibrations before they become troublesome. Imagine a future where metal lathes are not just gear-driven but smart! These advanced designs could boost efficiency and reduce noise. Exciting, right? In fact, studies show that improved designs could enhance productivity by 20%. Get ready for quieter and smoother operations!

| Trend | Description |

|---|---|

| Smart Sensors | Devices that detect vibrations in real-time. |

| AI Optimization | Using AI to improve lathe performance automatically. |

| Eco-Friendly Materials | New materials that reduce vibration and are good for the Earth. |

Conclusion

In summary, using gear systems can significantly reduce lathe vibration. This leads to smoother operations and better results. You can improve your machining by choosing the right gear for your metal lathe. Explore more about gear options and vibration control techniques. By doing so, you’ll enhance your skills and achieve higher-quality work!FAQs

What Are The Common Causes Of Vibration In Metal Lathes, And How Can Specific Gears Contribute To This Issue?Vibration in metal lathes can happen for a few reasons. First, if the machine is not on a solid surface, it can shake. Second, tools that aren’t tight can move and cause bumps. Lastly, worn-out gears can make the machine work unevenly, adding to the vibration. When gears are damaged or not aligned well, they can create extra movement, leading to more shaking.

What Techniques Can Be Employed To Reduce Vibration During The Operation Of A Metal Lathe?To reduce vibration when using a metal lathe, you can do a few things. First, make sure the lathe is on a sturdy, flat surface. You can also add weights or pads to help keep it steady. Using sharp tools can help too, as they cut better and create less shaking. Lastly, check that all parts are tight and secure to avoid extra movements.

How Does The Selection Of Gear Materials And Designs Impact The Overall Vibration Levels In A Lathe?The choice of materials and designs for gears affects how much a lathe shakes. Strong materials can make gears last longer and create less vibration. If gears are too heavy or poorly shaped, they can cause more shaking. A good design helps the lathe run smoothly, making it vibrate less during work. So, picking the right gear materials and designs helps keep everything stable and quiet.

What Role Do Dampening Systems Play In Managing Vibration In Metal Lathe Setups, Particularly Concerning Gear Interaction?Dampening systems help reduce vibrations in metal lathes. When gears interact, they can shake a lot. This shaking can mess up our work and make things less smooth. Dampening systems soak up these vibrations, making the machine run better. This way, we get more accurate and cleaner cuts on our metal.

How Can Regular Maintenance Of Gears And Other Components Help In Minimizing Vibration And Improving The Stability Of A Metal Lathe?Keeping gears and parts in good shape helps a metal lathe work better. When we clean and oil them, they move smoothly. This smooth movement cuts down on vibrations. Less vibration makes our projects more stable and accurate. Regular checks also help find problems early, so things don’t break.