Have you ever watched a metal lathe machine at work? It’s fascinating how it shapes metal into precise parts. But did you know that lathe vibration can be a big problem? Vibration can cause mistakes and reduce the quality of the final product. That’s where lathe vibration reduction comes in.

Imagine trying to draw with a shaky pencil. It’s hard, right? The same goes for a metal lathe machine. When it shakes, it can create rough surfaces or even ruin a piece altogether. Luckily, there are ways to reduce this vibration and improve your work.

In this article, we will explore some effective techniques for reducing lathe vibration. You’ll learn why it’s important and how it can help you create better and more reliable projects. Let’s dive into the world of lathe machines and discover how to make them work smoother and quieter!

Lathe Vibration Reduction For Metal Lathe Machines: Techniques

Lathe Vibration Reduction for Metal Lathe Machines

Reducing vibrations in metal lathe machines is crucial for better performance. High vibrations can lead to poor cuts and affect the machine’s lifespan. A stable lathe allows for smoother operations and improves accuracy. Have you ever noticed how even small shakes can ruin a project? By investing in vibration reduction technology, you can enhance workmanship and save time. Remember, a calm machine makes for happy results. Isn’t it fascinating how smooth operations can lead to better projects?Understanding Lathe Vibration

Definition and causes of vibration in metal lathes. Impact of vibration on machining accuracy and tool life.Vibration in metal lathes refers to unwanted movement during machining. It can happen due to poor setup, worn tools, or even the way the workpiece is placed. Think of it as a dance that went wrong; instead of twirling nicely, it stumbles! This vibration can affect machining accuracy, making parts not fit quite right. It also shortens tool life, like wearing out your favorite sneakers too quickly.

| Cause of Vibration | Impact |

|---|---|

| Poor setup | Decreased accuracy |

| Worn tools | Shorter tool life |

| Poor workpiece placement | Inconsistent machining |

Keeping vibrations in check helps machines run smoothly, like a well-oiled rollercoaster, ensuring both precision and longer tool use. So, let’s keep those lathes happy and dancing in rhythm!

Types of Lathe Vibration

Explanation of static vs. dynamic vibration. Common sources of vibration in metal lathe operations.Vibration in lathes can be a real pain, like that nagging friend who never leaves you alone. There are two main types: static and dynamic. Static vibration happens when the machine doesn’t wobble but may still shake in one spot. Dynamic vibration is when the entire machine jiggles like a bowl of jelly during a dance party. Common culprits of vibration in metal lathes include wear and tear, uneven cutting tools, and even the floor itself! Check out the table below for a quick look at the differences:

| Type | Description |

|---|---|

| Static Vibration | Stationary shakes at a specific point. |

| Dynamic Vibration | Shaking all over the place! |

Importance of Vibration Reduction

Effects on machining performance and product quality. Longterm benefits of reduced vibration for machinery maintenance.Reducing vibration in machines is very important. It helps machines run better and makes products high quality. Less vibration means less wear and tear on parts. This can save money on repairs over time. Also, machines last longer, which is good for everyone.

- Improved machining performance

- Enhanced product quality

- Lower maintenance costs

- Extended machine lifespan

Remember, happier machines mean better results!

Why is vibration reduction important?

Reducing vibration is key to better performance and product quality. It ensures smooth operations, leading to fewer mistakes during manufacturing.

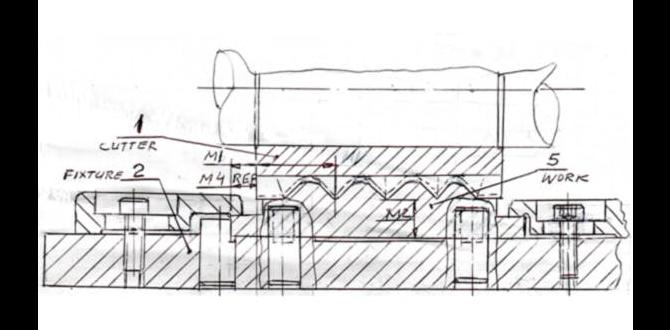

Material and Design Considerations

Impact of metal lathe construction materials on vibration. Design features that can help minimize vibration.Choosing the right materials for a metal lathe machine is important for reducing vibration. Heavy-duty metals, like cast iron, absorb vibrations better than lighter materials. This helps create smoother operations. Design features can also help minimize vibrations. Features such as:

- Sturdy base

- Vibration-damping feet

- Properly aligned components

Why do construction materials affect lathe vibrations?

Heavier materials absorb vibrations more effectively, leading to smoother machining. This means fewer issues with accuracy. The right materials can make a big difference in how well a lathe works.

Vibration Dampening Solutions

Types of dampers and their applications in lathe machines. Comparison of passive and active vibration control systems.Lathe machines can shake during use, causing problems. To fix this, people use dampers. There are mainly two types of dampers: passive and active. Passive dampers absorb energy and stop vibrations. Active dampers use sensors and motors to control vibrations in real-time. Both types improve machine performance.

- Passive Dampers: Simple and cost-effective.

- Active Dampers: More complex but better for real-time control.

Choosing the right damper improves the lathe vibration reduction metal lathe machine. Proper dampening leads to smoother operations and better results.

What are dampers used for in lathe machines?

Dampers are used to reduce vibrations in lathe machines, ensuring smooth and accurate machining.

Proper Setup and Maintenance Practices

Recommended practices for aligning and leveling metal lathes. Importance of regular maintenance to reduce vibration issues.Setting up your metal lathe correctly is like giving it a warm hug! Start by aligning and leveling it on a sturdy surface. This helps prevent those pesky vibrations that can make your work feel like you’re dancing the jitterbug! Regular maintenance is key. Clean it frequently and check for loose parts. Just like you wouldn’t ignore a sneeze, don’t ignore strange noises from your lathe—these could be signs of trouble brewing.

| Practice | Benefits |

|---|---|

| Align and level | Reduces vibrations |

| Regular cleaning | Prevents buildup |

| Inspect for loose parts | Avoilding accidents |

User-Driven Solutions and Best Practices

User testimonials and realworld experiences with vibration reduction techniques. Practical tips for operators to enhance vibration management efforts.User feedback can be a goldmine for improving lathe performance. Many operators report that simple changes made a big difference in reducing vibrations. Some suggest using flexible damping pads under machines to help absorb shocks. Others recommend checking if the workspace is level. It’s like ensuring your table is steady before enjoying a meal! Don’t forget, tightening loose bolts can work wonders, too. No one wants to dance when they should be cutting! Here’s a quick summary of user tips:

| Technique | Feedback |

|---|---|

| Flexible Damping Pads | Greatly reduces vibration! |

| Level Workspace | Stops unexpected table jiggles. |

| Tightening Bolts | Can prevent the lathe from doing the tango! |

These tips are like a recipe for smoother operation. Tackle vibrations, and your machine will thank you with better cuts! Remember to try and share your own stories!

Conclusion

In summary, reducing lathe vibration is crucial for better machining. It improves precision and extends your machine’s life. You can achieve this by maintaining your lathe, using sturdy mounts, and balancing your tools. For more tips, consider exploring articles on lathe maintenance. Remember, taking these steps will help you work more effectively and safely with your metal lathe machine!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction In Metal Lathe Machines:Sure! Here are five questions about reducing vibration in metal lathes. 1. Why does my lathe shake while I work? 2. What can we do to stop the shaking? 3. How does vibration change the way the metal cuts? 4. Can using different tools help with vibrations? 5. Why is it important to fix lathe vibrations? These questions help us understand how to make our lathes work better.

Sure! I’m ready to help. Please ask your question, and I will give you a clear and simple answer.

What Are The Primary Causes Of Vibration In Metal Lathe Machines, And How Can They Be Identified?Metal lathe machines can shake for a few reasons. First, they might have unbalanced parts. This happens when things like the motor or spindle aren’t even. Second, loose parts can make noise and shake. We can find these issues by checking if everything is tight and balanced. Sometimes, we can also see if the machine wobbles or feels rough when we use it.

What Role Do Machine Design And Construction Play In Reducing Lathe Vibrations During Operation?Machine design and construction help make lathes stronger. When we build them well, they stay stable while working. This stability reduces bumps and shakes, called vibrations, during use. Stronger materials and good shapes also help keep everything smooth. A smoother lathe means better work and lasting tools.

How Can The Use Of Vibration Dampening Materials And Techniques Improve The Performance And Precision Of A Metal Lathe?Using vibration dampening materials helps keep the metal lathe steady. When a lathe shakes, it can make parts that aren’t perfect. By reducing the shaking, we can cut metal more smoothly and accurately. This means our finished pieces will fit together better and work as they should. So, we get better results and save time!

What Are The Effects Of Lathe Vibration On Machining Accuracy, Tool Life, And Surface Finish?Lathe vibration can make it hard to cut materials accurately. This means you might get the wrong shape or size. It can also wear out your tools faster, which means you’ll have to replace them more often. Finally, vibrations can make surfaces rough instead of smooth, causing parts to look and feel bad. Keeping your lathe steady helps improve all these things.

What Preventive Maintenance Practices Can Be Implemented To Minimize Vibration In Metal Lathe Operations?To keep vibrations low in metal lathe operations, you can check for loose parts. Tighten any bolts or screws that aren’t secure. You should also keep the lathe clean to help it run smoothly. Lubricate moving parts regularly so they don’t grind together. Finally, balance the workpieces properly before starting to cut.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction In Metal Lathe Machines:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about reducing vibration in metal lathes. 1. Why does my lathe shake while I work? 2. What can we do to stop the shaking? 3. How does vibration change the way the metal cuts? 4. Can using different tools help with vibrations? 5. Why is it important to fix lathe vibrations? These questions help us understand how to make our lathes work better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I’m ready to help. Please ask your question, and I will give you a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Causes Of Vibration In Metal Lathe Machines, And How Can They Be Identified?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe machines can shake for a few reasons. First, they might have unbalanced parts. This happens when things like the motor or spindle aren’t even. Second, loose parts can make noise and shake. We can find these issues by checking if everything is tight and balanced. Sometimes, we can also see if the machine wobbles or feels rough when we use it.”}},{“@type”: “Question”,”name”: “What Role Do Machine Design And Construction Play In Reducing Lathe Vibrations During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine design and construction help make lathes stronger. When we build them well, they stay stable while working. This stability reduces bumps and shakes, called vibrations, during use. Stronger materials and good shapes also help keep everything smooth. A smoother lathe means better work and lasting tools.”}},{“@type”: “Question”,”name”: “How Can The Use Of Vibration Dampening Materials And Techniques Improve The Performance And Precision Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using vibration dampening materials helps keep the metal lathe steady. When a lathe shakes, it can make parts that aren’t perfect. By reducing the shaking, we can cut metal more smoothly and accurately. This means our finished pieces will fit together better and work as they should. So, we get better results and save time!”}},{“@type”: “Question”,”name”: “What Are The Effects Of Lathe Vibration On Machining Accuracy, Tool Life, And Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe vibration can make it hard to cut materials accurately. This means you might get the wrong shape or size. It can also wear out your tools faster, which means you’ll have to replace them more often. Finally, vibrations can make surfaces rough instead of smooth, causing parts to look and feel bad. Keeping your lathe steady helps improve all these things.”}},{“@type”: “Question”,”name”: “What Preventive Maintenance Practices Can Be Implemented To Minimize Vibration In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep vibrations low in metal lathe operations, you can check for loose parts. Tighten any bolts or screws that aren’t secure. You should also keep the lathe clean to help it run smoothly. Lubricate moving parts regularly so they don’t grind together. Finally, balance the workpieces properly before starting to cut.”}}]}