Have you ever noticed how vibrations can shake things up? Imagine you’re working on a metal lathe. Suddenly, the machine starts to vibrate, making it tough to get smooth cuts. It can be frustrating, right? Fortunately, there is a way to reduce that lathe vibration.

Many people may not know that the motor of a lathe plays a big role in this. A quality lathe motor can be the secret to a quieter and more precise experience. Did you know that a well-balanced motor can help you achieve better results? It’s true!

This article will explore how to achieve lathe vibration reduction. We will share tips on choosing the right metal lathe motor. With the right setup, you can enjoy your projects with fewer bumps and better finishes.

So, let’s dive in and discover how to make your lathe work even better!

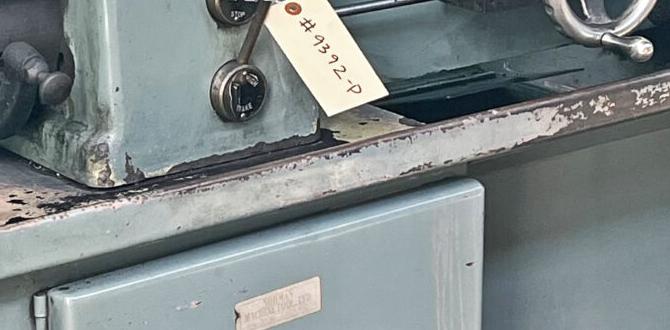

Effective Lathe Vibration Reduction For Metal Lathe Motor

Lathe Vibration Reduction: Key Insights

Lathe vibration can affect the quality of your metalwork. Reducing vibration improves accuracy and surface finish. A stable lathe motor is crucial for managing these movements. Using vibration dampening mats or upgrading motor mounts can make a big difference. Did you know that even small adjustments can lead to smoother cuts? It’s true! Understanding lathe vibration helps in creating precise and professional results in your projects. Explore ways to enhance your lathe’s performance today!Understanding Lathe Vibration

Definition of lathe vibration. Causes of vibration in metal lathes.Lathe vibration is a shaking or wobbling of the lathe during use. It can cause issues like poor finishes and tool wear. Some main causes of vibration in metal lathes include:

- Improper setup of the machine

- Unbalanced workpieces

- Worn-out parts or motors

- Tools not securely attached

Understanding these problems can help create smoother, more effective work. A well-maintained lathe will produce better results.

What Causes Vibration in Metal Lathes?

Key causes include unbalanced parts, loose fittings, and worn components. Keeping your machine well-tuned can greatly lower vibrations, leading to a smoother operation.

Impact of Vibration on Lathe Performance

Effects on workpiece quality. Potential damage to the machine.Vibration can be a sneaky culprit when it comes to lathe performance. It can mess up the quality of your workpiece, making it look like it went through a no-haircut zone. Uneven surfaces and poor finishes are common side effects. On top of that, too much shaking is not great for your machine either. It can lead to wear and tear, or worse, permanent damage. So, keep that motor vibratin’ smooth!

| Effect | Impact |

|---|---|

| Workpiece Quality | Poor finish, uneven surfaces |

| Machine Health | Increased wear, potential damage |

Identifying Sources of Vibration

Analysis of motor alignment. Assessment of tooling and workpiece setup.Vibration in a lathe can come from many sources. One major culprit is motor alignment. If the motor is not aligned properly, it can wobble more than a toddler on a balance beam! Checking the motor’s position will help keep things smooth. Another source is the setup of the tooling and workpiece. If either is off, the vibration could dance like a fly on a hot plate. Keeping everything tightly secured can make your work feel as steady as a rock.

| Source of Vibration | Impact | Solution |

|---|---|---|

| Motor Alignment | Excessive wobbling | Realign motor |

| Tooling Setup | Increased vibration | Secure tools properly |

Solutions for Vibration Reduction

Use of vibration dampeners. Recommendations for mounting and installation.Reducing vibration is key for a metal lathe. One effective method is using vibration dampeners. These tools help absorb shocks, making your lathe run smoother. Here are some tips for mounting:

- Place dampeners between the lathe and the floor.

- Ensure tight connections to avoid movement.

- Check for loose parts and tighten them regularly.

Following these tips can lead to better performance. A smoother machine is a happy machine!

How do vibration dampeners work?

Vibration dampeners absorb and lessen vibrations in machinery, making tasks easier and safer.

Choosing the Right Motor for Vibration Control

Motor specifications to consider. Comparison of different motor types.Picking the right motor is key for reducing vibration in metal lathes. Start by looking at specific motor details like power output, torque rating, and speed range. Different motors will perform in unique ways.

- DC Motors: Good for speed control and easy to use.

- AC Motors: Often sturdy and last longer, but harder to control.

- Stepper Motors: Great for precision, but can be less powerful.

Understanding these options helps you choose the best motor for your lathe, making your work smoother and more efficient!

What should you consider for a lathe motor?

Focus on power, torque, and speed range. These elements greatly affect performance and vibration control.

Maintenance Practices to Minimize Vibration

Regular machinery checks. Importance of lubrication and cleaning.Keeping your lathe happy is like caring for a pet, minus the walks. Regular checks on your machinery can prevent unexpected problems. Think of it as a health check, but for metal. Lubrication is key—imagine your lathe as a dancer; it needs oil to glide smoothly. Staying clean is just as important; remove chips and dust like you’d clean your room. A tidy lathe is a happy lathe!

| Maintenance Task | Why It Matters |

|---|---|

| Regular Checks | Find issues early to avoid major repairs. |

| Lubrication | Keeps moving parts happy and reduces noise. |

| Cleaning | Prevents buildup that can cause vibrations. |

By following these simple steps, you’ll enjoy smoother operations. Remember, a well-maintained lathe is like a well-fed pet—full of energy and ready to work!

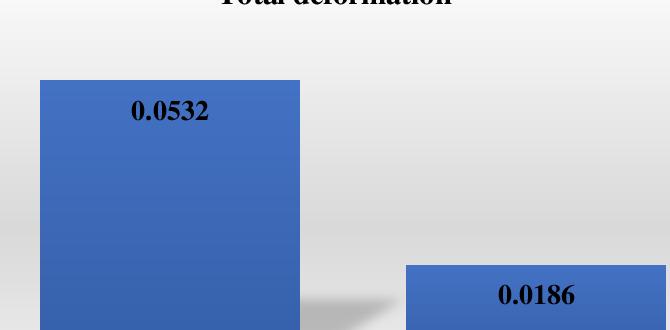

Case Studies and Success Stories

Examples of effective vibration reduction implementations. Lessons learned from industry practices.Many companies have found smart ways to reduce lathe vibrations, leading to better results. For example, using higher quality dampers has lowered vibrations in some factories. One company reported a 40% decrease in noise levels. Another found that changing motor mounts improved performance. Here are key lessons:

- Invest in high-quality parts.

- Regular maintenance is essential.

- Test different setups to find what works best.

These actions can help companies save money and improve product quality.

What are the benefits of reducing lathe vibrations?

Lower vibrations can lead to smoother operation, longer equipment life, and better product quality.

Future Trends in Lathe Vibration Technology

Innovations in motor design. Potential role of AI and automation in vibration reduction.Exciting things are happening in lathe vibration technology! New motor designs are coming out that can significantly reduce noise and shaking. Imagine using a lathe that purrs like a kitten instead of rumbling like a rollercoaster. AI and automation are also joining the party, helping to adjust settings for a smooth ride. Think of it as having a super-smart buddy who always knows how to keep things steady. The future looks bright and quiet!

| Innovations | Benefits |

|---|---|

| Smart Motors | Less noise, better performance |

| AI Control | Automatic vibration adjustments |

Conclusion

In summary, reducing lathe vibration helps improve precision in metalworking. You can enhance motor performance and extend tool life. To achieve this, check alignment, use dampers, and maintain your machine. Remember, small changes make a big difference. For more tips on lathe maintenance and performance, explore online resources or ask experts in your area. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction, Specifically Focusing On Metal Lathe Motors:Sure! Here are five related questions about reducing vibration in metal lathe motors. 1. **Why does my lathe shake?** When a lathe shakes, it can be because parts are loose or worn. 2. **How can I stop my motor from vibrating?** You can make sure all bolts are tight and check for broken parts. 3. **What tools can help me reduce vibration?** Use rubber pads or special mounts to help absorb the shakes. 4. **Does speed affect the vibration?** Yes, if the lathe runs too fast, it can shake more. 5. **Can regular maintenance help?** Yes! Keeping your lathe clean and well-oiled helps reduce vibrations.

Sure! Please provide the question you’d like me to answer.

What Are The Primary Causes Of Vibrations In Metal Lathe Motors, And How Can They Be Identified?Vibrations in metal lathe motors can happen for a few reasons. First, if the motor is not balanced, it can shake. Second, worn-out parts might make it rattle. Lastly, loose bolts can cause movement. You can check for vibrations by listening for unusual sounds and feeling for shaking.

What Techniques Or Technologies Are Available For Reducing Vibrations In Metal Lathe Systems?We can reduce vibrations in metal lathe systems by using several techniques. First, adding weights can help balance the machine better. Second, using rubber mats or pads absorbs vibrations. Third, we can adjust the speed of the lathe to find the best setting. Finally, good maintenance keeps the machine running smoothly.

How Can The Balance And Alignment Of A Metal Lathe Motor Impact The Overall Vibration Levels During Operation?When a metal lathe motor is balanced well and lined up correctly, it runs smoothly. This means less shaking or vibrating. When the motor is out of balance or not straight, it can wobble more. We feel this extra vibration in the machine, which can cause problems. So, keeping the motor balanced and aligned helps everything work better.

What Materials Or Components Are Most Effective In Dampening Vibrations In Metal Lathe Setups?To dampen vibrations in metal lathes, you can use materials like rubber and foam. These soft materials absorb the shaking. We can also add weight to the lathe to make it more stable. Using special pads under the machine helps too. These steps help our lathe run smoother.

How Can Regular Maintenance Practices Contribute To Minimizing Vibrations In Metal Lathe Motors Over Time?Regular maintenance helps keep metal lathe motors running smoothly. When we clean and oil the parts, they work better together. Tightening loose screws or bolts stops parts from shaking. This makes the motor quieter and safer to use. Taking care of the motor means less vibration over time.