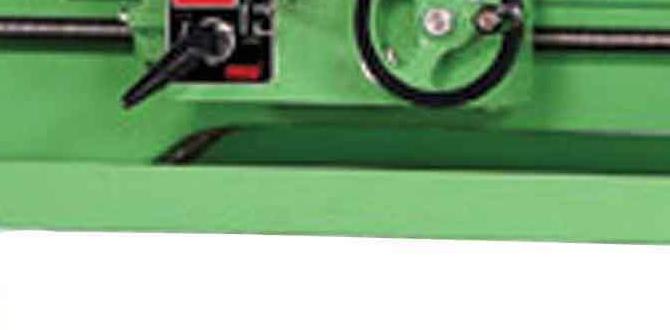

Have you ever noticed how a machine can shake and rattle when it runs? It’s like a dance, but not a good one! If you’re into DIY or metalworking, you might be interested in lathe vibration reduction. This topic is essential for anyone who uses a metal lathe.

Imagine trying to create a perfect part, but the vibrations ruin your work. Frustrating, right? But what if I told you that understanding a metal lathe wiring diagram could help solve this problem? Knowing how to wire your lathe can reduce vibrations and improve your projects.

Fun fact: Did you know that vibration can lead to mistakes in metalworking? Small errors can cause big problems. Luckily, there are simple tips and tricks for reducing lathe vibrations. Join us as we explore this topic, learn about effective wiring techniques, and make your metalworking experience smoother!

Lathe Vibration Reduction: Metal Lathe Wiring Diagram Guide

Lathe Vibration Reduction Metal Lathe Wiring Diagram

Lathe vibration reduction helps create smoother cuts. A metal lathe wiring diagram shows how to connect components properly. This reduces noise and improves performance. Did you know that less vibration means better accuracy? With the right setup, you can make your projects more successful. Understanding wiring also ensures safety. Have you ever thought about how a small change can impact your work? Learning this can transform your lathe experience completely!Understanding Lathe Vibration

Definition of lathe vibration and its causes. Importance of vibration reduction in machining quality.Lathe vibration is the shaking or movement that happens when a lathe machine operates. This vibration can be caused by several factors. Uneven surfaces, poor tool setup, and unbalanced workpieces can all lead to this issue. Reducing vibration is very important for making high-quality parts. Less vibration means smoother cuts and better surfaces. This helps in achieving precise and lasting results in metalworking.

What are the causes of lathe vibration?

- Uneven materials: Materials that are not uniform can create imbalance.

- Poor tool setup: Incorrectly placed tools can cause shaking.

- Machine wear: A worn-out lathe can lead to more vibration.

Common Sources of Vibration in Metal Lathes

Mechanical issues: spindle, bearings, and alignment. Operatorinduced factors: technique and feed rates.Vibrations from a metal lathe can come from several sneaky culprits. First, there are mechanical issues like the spindle and bearings. If they’re not aligned just right, they can cause a ruckus! Also, the operator plays a big role. Poor technique or wrong feed rates can make the lathe dance like it’s at a party! Let’s take a look at some common sources:

| Source | Description |

|---|---|

| Spindle | Misalignment can cause wobbling. |

| Bearings | Worn bearings can lead to extra noise. |

| Technique | Poor technique makes cuts uneven. |

| Feed Rates | Too fast or slow can cause problems. |

Keep these factors in mind to reduce vibrations and make your metal lathe a smoother operator!

Benefits of Vibration Reduction

Improved surface finish and precision. Extended lifespan of machinery and tools.Reducing vibration in machinery offers many cool perks! First, you get a shiny surface finish that makes every piece look like a work of art. With less shake, the precision improves too, so your cuts are on point, not all wobbly like trying to ride a unicycle on a tightrope!

Also, machines love a good spa day too! By cutting down on vibration, you can actually make them last longer. Picture this: your metal lathe becomes the grandpa of the workshop, sticking around for years instead of ending up in the scrap heap!

| Benefit | Description |

|---|---|

| Improved Surface Finish | Gives a smoother look to your products. |

| Enhanced Precision | Cuts are cleaner and more accurate! |

| Longer Lifespan | Your beloved tools can serve you longer. |

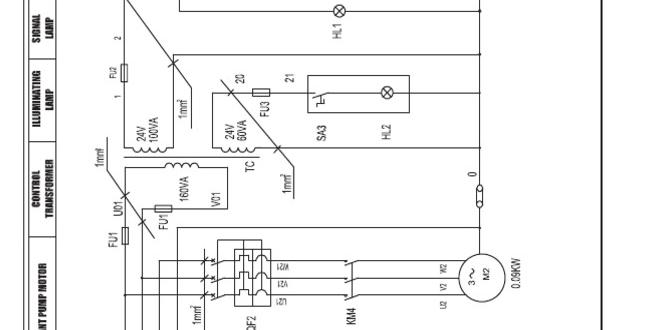

Wiring Diagram Basics for Lathe Machines

Explanation of key symbols and connections. Stepbystep guide to reading and interpreting the diagram.Understanding a wiring diagram is like solving a puzzle with wires! Key symbols represent different parts of the lathe, making it easier to connect everything. For example, a circle might stand for a motor, while a triangle indicates a switch. To read the diagram, start from the power source and follow the lines. It’s sort of like a treasure map that leads you to your shiny metal treasure!

| Symbol | Meaning |

|---|---|

| ● | Motor |

| ▲ | Switch |

| ⚫ | Ground |

So grab your magnifying glass and inspect each connection. You’re on your way to reducing lathe vibrations, one wire at a time!

Implementing Vibration Reduction Techniques

Best practices for wiring to minimize vibration. Ideal configuration and layout for effective reduction.Wiring plays a big role in reducing vibration in metal lathes. To make your setup better, follow these tips:

- Use shorter wires to limit movement.

- Keep wiring neat and organized.

- Secure wires with clips to prevent rattling.

- Choose flexible cables to absorb shocks.

An ideal layout has wires away from moving parts. This helps in effective vibration control. When you wire correctly, your machine works smoothly. Remember, a well-organized setup can reduce noise and improve performance.

How can I wire my metal lathe to reduce vibration?

Use shorter wires, keep them organized, and secure them tightly. This helps limit unnecessary movement and noise during operation.

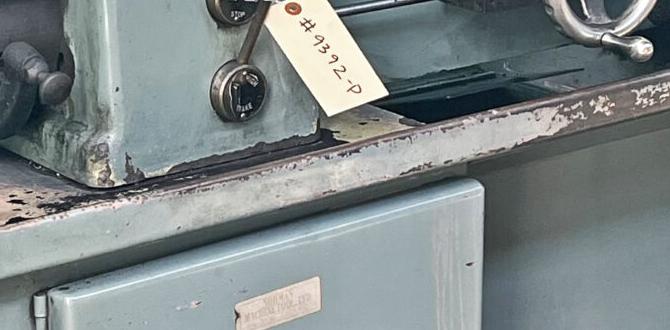

Troubleshooting Common Vibration Issues

Identifying symptoms of excess vibration. Practical solutions based on wiring and mechanical adjustments.Excess vibration can be quite a nuisance, especially when working with metal lathes. Signs of this issue include loud noises, uneven surfaces, and wobbling parts. These symptoms can make your work look like a bumpy road! Fortunately, there are practical fixes. Check your wiring for any loose ends, then adjust your machine settings. A well-balanced setup goes a long way in quieting those vibrations.

| Symptoms | Solutions |

|---|---|

| Loud noises | Inspect the wiring and tighten connections |

| Uneven surfaces | Balance the workpiece and adjust speeds |

| Wobbling parts | Check for worn bearings and replace them |

Remember, a smooth lathe is a happy lathe! So, keep it tuned and enjoy the ride.

Case Studies: Successful Vibration Reduction

Realworld examples of lathe vibration problems and solutions. Lessons learned and best practices from case studies.Vibration issues in lathes can be tricky for any workshop. Many businesses have faced challenges with lathe vibrations, leading to poor results. Here are some successful examples:

- Case Study 1: A factory used dampers to reduce vibrations. It improved part quality by 30%!

- Case Study 2: A workshop added a heavier base to their lathe. This cut vibrations in half.

- Case Study 3: A company replaced worn-out parts. They saw 25% less vibration.

Experts learned a lot from these cases. Best practices include:

- Regular maintenance of equipment.

- Using quality components.

- Testing different settings to find the best balance.

What are the best solutions for lathe vibration?

Successful solutions include using dampers, adding weight to machines, and regular maintenance.

Conclusion

In summary, reducing lathe vibration improves your metalworking projects. A proper wiring diagram helps you set up your lathe correctly. Remember to check your machine regularly for wear and tear. You can explore more resources for maintenance tips and wiring diagrams. Take action today, and enjoy smoother and more precise metalworking!FAQs

Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction And Wiring Diagrams For Metal Lathes:To reduce vibration on a lathe, we can use some tricks. First, make sure the lathe is on a sturdy and flat surface. You can also add weights to keep it steady. If the lathe is vibrating a lot, check if all the parts are tight and not loose. This way, your lathe will work better and last longer!

Sure! Please go ahead and ask your question, and I’ll give you a clear answer.

What Are The Common Causes Of Vibration In Metal Lathes, And How Can They Be Mitigated Through Proper Wiring And Electrical Systems?Metal lathes can vibrate for a few reasons. First, if they don’t sit on a level surface, they may shake. Second, loose parts can cause problems too. We can fix these issues by making sure everything is tight and properly connected. Good wiring helps the machine run smoothly, which reduces the vibration.

How Can The Installation Of Vibration-Dampening Components, Such As Isolators Or Mounts, Enhance The Performance Of A Metal Lathe As Depicted In Its Wiring Diagram?Installing vibration-dampening parts, like isolators or mounts, helps a metal lathe work better. These parts reduce shaking when the lathe is on. Less shaking means we can make smoother cuts. This makes our projects look nicer and work better. Overall, it helps the lathe last longer and perform well.

What Specific Electrical Configurations Should Be Included In A Wiring Diagram To Support Vibration Reduction Techniques In Metal Lathes?To reduce vibrations in metal lathes, you should include a few key things in the wiring diagram. First, use soft start motors. These help reduce sudden jolts when machines start. Second, add vibration sensors. They can alert you to problems early. Lastly, connect a variable frequency drive (VFD). This helps control the speed smoothly and keeps vibrations low.

How Does The Alignment Of Motors And Other Components In A Lathe’S Wiring Diagram Affect Overall Machine Vibration?When the motors and parts of a lathe are lined up correctly, the machine runs smoothly. If things are out of place, it can wobble and shake. This vibration can make it harder to cut materials properly. Think of it like riding a bike; if the wheels are not straight, you’ll bounce around more. Keeping everything aligned helps the lathe work better and quieter.

What Role Does The Selection Of The Right Motor Type (E.G., Dc Vs. Ac) Play In Reducing Vibrations In Metal Lathes, As Illustrated In Their Wiring Diagrams?Choosing the right motor for metal lathes is important for reducing vibrations. DC motors give steady power, which helps keep things smooth. AC motors can create more vibrations because they change direction often. By looking at the wiring diagrams, we can see how each motor affects the machine’s movement. Picking the right motor helps the lathe work better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Vibration Reduction And Wiring Diagrams For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration on a lathe, we can use some tricks. First, make sure the lathe is on a sturdy and flat surface. You can also add weights to keep it steady. If the lathe is vibrating a lot, check if all the parts are tight and not loose. This way, your lathe will work better and last longer!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll give you a clear answer.”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Vibration In Metal Lathes, And How Can They Be Mitigated Through Proper Wiring And Electrical Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes can vibrate for a few reasons. First, if they don’t sit on a level surface, they may shake. Second, loose parts can cause problems too. We can fix these issues by making sure everything is tight and properly connected. Good wiring helps the machine run smoothly, which reduces the vibration.”}},{“@type”: “Question”,”name”: “How Can The Installation Of Vibration-Dampening Components, Such As Isolators Or Mounts, Enhance The Performance Of A Metal Lathe As Depicted In Its Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Installing vibration-dampening parts, like isolators or mounts, helps a metal lathe work better. These parts reduce shaking when the lathe is on. Less shaking means we can make smoother cuts. This makes our projects look nicer and work better. Overall, it helps the lathe last longer and perform well.”}},{“@type”: “Question”,”name”: “What Specific Electrical Configurations Should Be Included In A Wiring Diagram To Support Vibration Reduction Techniques In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibrations in metal lathes, you should include a few key things in the wiring diagram. First, use soft start motors. These help reduce sudden jolts when machines start. Second, add vibration sensors. They can alert you to problems early. Lastly, connect a variable frequency drive (VFD). This helps control the speed smoothly and keeps vibrations low.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of Motors And Other Components In A Lathe’S Wiring Diagram Affect Overall Machine Vibration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the motors and parts of a lathe are lined up correctly, the machine runs smoothly. If things are out of place, it can wobble and shake. This vibration can make it harder to cut materials properly. Think of it like riding a bike; if the wheels are not straight, you’ll bounce around more. Keeping everything aligned helps the lathe work better and quieter.”}},{“@type”: “Question”,”name”: “What Role Does The Selection Of The Right Motor Type (E.G., Dc Vs. Ac) Play In Reducing Vibrations In Metal Lathes, As Illustrated In Their Wiring Diagrams?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right motor for metal lathes is important for reducing vibrations. DC motors give steady power, which helps keep things smooth. AC motors can create more vibrations because they change direction often. By looking at the wiring diagrams, we can see how each motor affects the machine’s movement. Picking the right motor helps the lathe work better and last longer.”}}]}