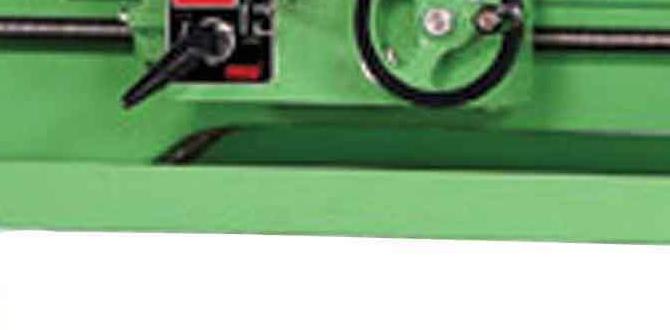

Have you ever seen a metal lathe in action? It’s a fascinating machine that shapes metal into amazing designs. But did you know that with some clever lathe wiring, you can make it even smarter? That’s right! Automation in metal lathes is changing how we work with these machines.

Imagine walking into a workshop where the lathes can think for themselves. They can adjust speeds and tools all on their own. This makes work quicker and more efficient. Who wouldn’t want that? If you love building or creating things, understanding lathe wiring opens a whole new world of possibilities.

In this article, we will explore how automation changes the game for metal lathe users. You will learn easy ways to wire your lathe and the advantages of automating it. Let’s dive in and see what these machines can really do!

Lathe Wiring For Metal Lathe Automation: A Comprehensive Guide

Lathe Wiring and Metal Lathe Automation

Lathe wiring connects all machine parts for smooth operation. Automation in metal lathes makes tasks easier and faster. Imagine how helpful it is when a machine runs itself! This technology reduces human error and boosts efficiency. You can create precise items with less effort. Plus, learning about lathe wiring can empower hobbyists and professionals alike. Isn’t it exciting to think about how automation can revolutionize the way we work with metal?Types of Lathes and Their Wiring Needs

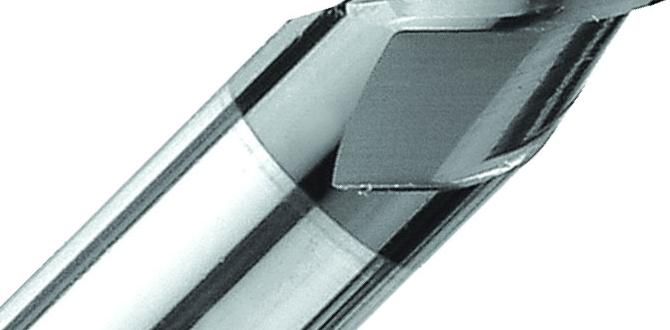

Comparison of manual vs. CNC lathes. Specific wiring requirements for each type.Different types of lathes serve unique purposes in metalwork. Manual lathes need simple wiring for power, and operators control them by hand. In contrast, CNC lathes use computers. Their wiring is more complex since they need commands from software. Here are some key differences:

- Manual Lathes: Basic wiring, easy to operate

- CNC Lathes: Advanced wiring, automated operation

CNC lathes can perform intricate tasks quickly. They save time and effort but require skilled technicians for wiring and maintenance.

What are the wiring needs for each type of lathe?

Manual lathes need simple electrical connections, while CNC lathes require detailed wiring for complex operations.

Essential Tools and Materials for Lathe Wiring

List of tools needed for lathe wiring. Recommended wiring materials for durability and efficiency.To wire a lathe, you need a few important tools. These tools make the job easier and help create better results. Here are the main ones:

- Wire cutters

- Screwdrivers

- Heat shrink tubing

- Electrical tape

- Multimeter

For materials, choosing durable wiring is key. It ensures your lathe runs smoothly. Use high-quality copper wire. Copper is strong and conducts electricity well. This helps with efficiency. Additionally, use heat shrink tubing for insulation. It protects against wear and tear.

What tools do I need for lathe wiring?

You will need wire cutters, screwdrivers, heat shrink tubing, electrical tape, and a multimeter.

Step-by-Step Guide to Wiring a Metal Lathe

Detailed wiring process for a standard metal lathe. Common mistakes to avoid during wiring.Wiring a metal lathe might sound tough, but it’s like piecing together a puzzle. First, gather your tools and check the machine’s manual. Follow the color-coded wires—they can be your best friends! Avoid common mistakes like mixing wire colors; it’s not a fashion show! Always double-check your connections before turning it on. A bad connection can lead to sparks, and not the romantic kind. Here’s a small table of things to remember:

| Connection | Tip |

|---|---|

| Power Supply | Ensure it’s off before starting. |

| Terminal Connections | Match colors correctly! |

| Ground Wire | Always connect it first! |

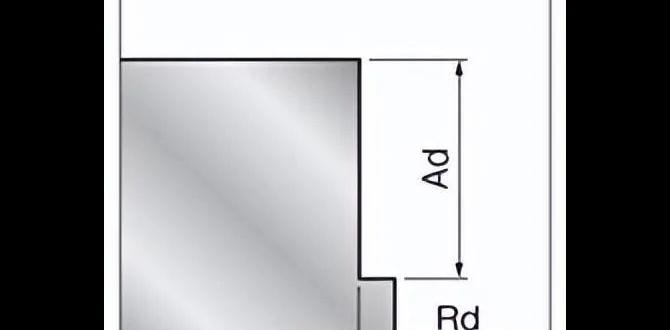

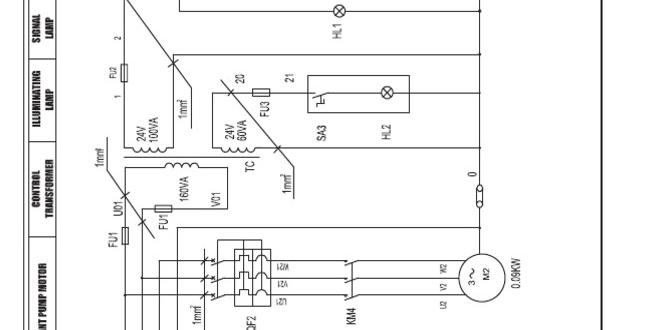

Advanced Wiring Techniques for Lathe Automation

Wiring modifications for enhanced automation. Understanding control systems for automated lathes.Upgrading your lathe’s wiring can transform it into a smart machine. Proper wiring modifications boost automation, letting you sit back while the lathe does the work. Understanding the control system is crucial. Think of it as the brain of your lathe—make sure it’s wired right! Confused? Don’t worry; even the best mechanics had a moment when they thought a circuit was a dance move! Just remember, better wiring leads to better results.

| Wiring Components | Function |

|---|---|

| Sensors | Detect material and position |

| Controllers | Manage movements and processes |

| Actuators | Translate the control signals into motion |

Maintenance and Troubleshooting of Lathe Wiring

Regular maintenance tips to ensure longlasting performance. Common troubleshooting steps for wiring issues.To keep your lathe wiring in shape, regular maintenance is key. Check and tighten connections. Clean dust and debris often. Replace worn wires to avoid problems. Here are some common troubleshooting tips for wiring issues:

- Look for loose connections.

- Check for damaged wires.

- Test the power supply.

By following these tips, you can ensure your lathe runs smoothly for a long time.

What are the steps for basic lathe wiring troubleshooting?

Common steps include checking connections for tightness, inspecting wires for damage, and ensuring the power supply is working properly.

Future Trends in Metal Lathe Automation

Emerging technologies in lathe automation. Predictions for the future of metal lathe wiring and automation.New technologies are changing how metal lathes work. Robotics, sensors, and AI make lathe automation faster and smarter. These tools help workers save time and reduce mistakes. In the future, we might see:

- Advanced Robotics: Machines that can do more tasks without help.

- Better Sensors: Tools that can detect errors before they happen.

- Machine Learning: Lathes that learn from each job and improve over time.

- Remote Monitoring: Control machines from anywhere, ensuring efficiency.

This automation means more precise and efficient work. With these trends, we can expect metal lathes to be even more powerful and reliable.

What are key emerging technologies for lathe automation?

Emerging technologies include robotics, AI, and advanced sensors. These tools work together to make lathes faster and more accurate.Conclusion

In conclusion, lathe wiring and metal lathe automation can greatly improve your machining work. By understanding wiring basics, you can enhance safety and efficiency. Automation helps save time and increases precision in your projects. We encourage you to explore tutorials and guides to get started with your own lathe automation. Dive in, and enjoy the journey of learning!FAQs

What Are The Essential Components Required For Automating A Metal Lathe, And How Do They Integrate With Existing Wiring Systems?To automate a metal lathe, you need a computer, sensors, and motors. The computer sends commands to the motors, making the lathe move. Sensors help the computer know where the lathe is and if it’s working correctly. We connect these parts to the existing wiring so they can all talk to each other and work together. This way, the lathe can run smoothly and do its job better.

Sure, I can help with that! Just tell me what question you want me to answer.

How Can I Safely Wire A Cnc Control System To My Manual Metal Lathe For Basic Automation Operations?To safely wire a CNC control system to your manual metal lathe, first, unplug all machines. Next, use a wiring guide that comes with your CNC unit. Connect the wires from the CNC control to the lathe’s power and motor parts, following the guide carefully. Always double-check your connections before plugging everything back in. Finally, test the system slowly to make sure everything works without problems.

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.

What Wiring Considerations Should Be Taken Into Account When Upgrading A Conventional Metal Lathe For Automated Functions?When upgrading a metal lathe for automation, you need to think about a few things. First, make sure the wires can handle higher power. We also need to check that the connections are secure and safe. You might want to add sensors, which need proper wiring and placement. Lastly, don’t forget to use good insulation to prevent any shocks or short circuits.

Sure! Please provide the question you would like me to answer, and I’ll be happy to help.

What Types Of Sensors And Feedback Systems Can Be Incorporated Into The Wiring Of A Metal Lathe To Enhance Automation And Precision?To make a metal lathe better, we can use different sensors and feedback systems. You can add a position sensor to know exactly where the tool is. A temperature sensor can check if the machine is getting too hot. We can also use a speed sensor to monitor how fast the lathe is turning. These sensors help us control the lathe better and make more precise parts.

Sure! Please provide the question you want me to answer, and I’ll be happy to help.

What Common Wiring Mistakes Should Be Avoided When Setting Up An Automated Metal Lathe To Ensure Optimal Performance And Safety?When setting up an automated metal lathe, make sure you connect the wires correctly. Check that the power wires are not mixed up with control wires. Always secure loose wires to prevent them from getting caught or damaged. Avoid using wires that are too thin, as they may overheat. Finally, don’t forget to turn off the power before you start working on the machine.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Required For Automating A Metal Lathe, And How Do They Integrate With Existing Wiring Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To automate a metal lathe, you need a computer, sensors, and motors. The computer sends commands to the motors, making the lathe move. Sensors help the computer know where the lathe is and if it’s working correctly. We connect these parts to the existing wiring so they can all talk to each other and work together. This way, the lathe can run smoothly and do its job better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, I can help with that! Just tell me what question you want me to answer.”}},{“@type”: “Question”,”name”: “How Can I Safely Wire A Cnc Control System To My Manual Metal Lathe For Basic Automation Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely wire a CNC control system to your manual metal lathe, first, unplug all machines. Next, use a wiring guide that comes with your CNC unit. Connect the wires from the CNC control to the lathe’s power and motor parts, following the guide carefully. Always double-check your connections before plugging everything back in. Finally, test the system slowly to make sure everything works without problems.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Wiring Considerations Should Be Taken Into Account When Upgrading A Conventional Metal Lathe For Automated Functions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading a metal lathe for automation, you need to think about a few things. First, make sure the wires can handle higher power. We also need to check that the connections are secure and safe. You might want to add sensors, which need proper wiring and placement. Lastly, don’t forget to use good insulation to prevent any shocks or short circuits.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Feedback Systems Can Be Incorporated Into The Wiring Of A Metal Lathe To Enhance Automation And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe better, we can use different sensors and feedback systems. You can add a position sensor to know exactly where the tool is. A temperature sensor can check if the machine is getting too hot. We can also use a speed sensor to monitor how fast the lathe is turning. These sensors help us control the lathe better and make more precise parts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Common Wiring Mistakes Should Be Avoided When Setting Up An Automated Metal Lathe To Ensure Optimal Performance And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up an automated metal lathe, make sure you connect the wires correctly. Check that the power wires are not mixed up with control wires. Always secure loose wires to prevent them from getting caught or damaged. Avoid using wires that are too thin, as they may overheat. Finally, don’t forget to turn off the power before you start working on the machine.”}}]}