Have you ever wondered how metal parts are made with precision? The world of lathe wiring and metal lathe CAD design holds the answer. These tools help create amazing shapes and objects from metal. But what do these fancy terms really mean?

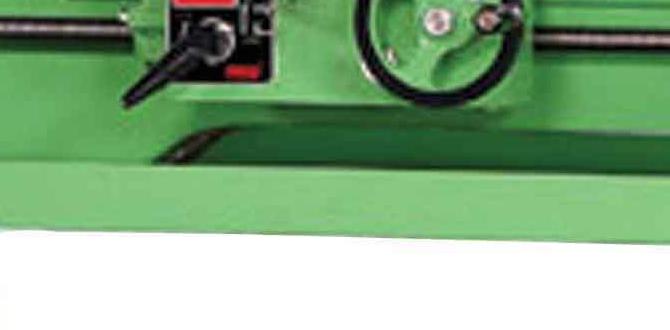

Imagine you are building a small robot or a fun toy car. You need the right parts that fit together well. That’s where a metal lathe comes in. It spins metal pieces, allowing you to carve them into perfect shapes.

Lathe wiring ties everything together. It connects the machine’s motors and controls. Without proper wiring, the lathe can’t work its magic. Plus, CAD design steps in to help you visualize your ideas before you even begin working with metal!

Here’s a fun fact: Did you know that woodworkers and metalworkers both use lathes? They each create beautiful items, but with different materials. Isn’t it exciting how one tool can serve so many purposes?

Stay curious as we dive deeper into the fascinating world of lathe wiring and metal lathe CAD design. There’s so much to discover!

Lathe Wiring: Understanding Metal Lathe Cad Design

Understanding Lathe Wiring and CAD Design

When working with a metal lathe, wiring is crucial. Proper wiring ensures the machine runs smoothly and safely. Have you ever thought about how designs come to life? Computer-Aided Design (CAD) helps create detailed lathe projects with precision. Imagine crafting an intricate part just using a sketch on your computer. With CAD, you can visualize and improve your designs before going to the lathe. This technology transforms ideas into reality. Discovering lathe wiring and CAD design can open up exciting possibilities in metalworking!Components of Lathe Wiring Systems

Key electrical components used in lathe wiring. Role of each component in the lathe operation.In lathe wiring systems, several key electrical components work together. Each plays a big role in making the lathe run smoothly. Here are the main parts:

- Power Supply: This provides the necessary electricity for operation.

- Switches: They control the start and stop of the machine.

- Motor: The motor spins the lathe, making it do its job.

- Wiring: Wires connect all parts, ensuring power flows correctly.

- Control Panel: It allows users to adjust settings easily.

Understanding these components helps in making better metal lathe CAD designs.

What are the main electrical components of lathe wiring?

The main parts include power supply, switches, motors, wiring, and control panels. Each part must work well together for the lathe to function properly.

These components connect like pieces in a puzzle. They support one another to achieve precise cutting and shaping. This teamwork is vital for successful lathe operations.

CAD Design for Metal Lathes

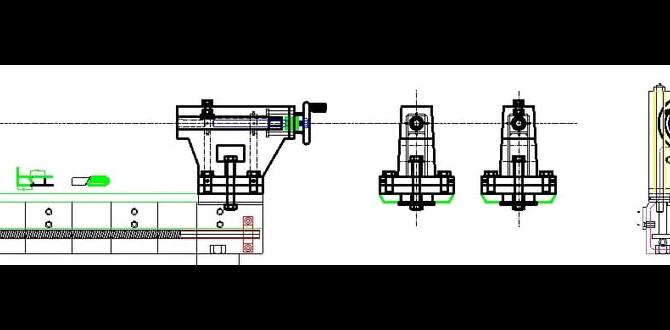

Basics of CAD software used in lathe design. Steps to integrate wiring layout into CAD designs.CAD software is like the superhero of metal lathe design. It helps you create cool blueprints for your projects without any sweat. First, you make a plan using simple shapes and lines. Next, you can add details like where the wires will go. Integrating a wiring layout into your design is as fun as adding toppings to a pizza. Just make sure to keep everything neat and tidy!

| Step | Description |

|---|---|

| 1 | Open CAD software and set up your workspace. |

| 2 | Create a 2D design of your lathe. |

| 3 | Add your wiring layout on top of the design. |

| 4 | Check for errors and make adjustments. |

| 5 | Save your design and get ready to build! |

This process makes it easy to avoid mistakes and keeps everything organized. Remember, good design is key to a successful project! So, let’s save those wires from getting tangled like spaghetti!

Safety Considerations for Lathe Wiring

Essential safety practices when dealing with lathe wiring. Common hazards and how to mitigate them.Wiring a lathe can be tricky, but safety is key. Always wear protective gear like goggles and gloves. Remember, those wires can bite if you’re not careful! Common hazards include electric shock and moving parts. Keep your workspace tidy to avoid trip hazards. If you feel unsure, ask for help! Using a circuit breaker can save you from the shock of your life. Below is a quick guide to keep you safe:

| Safety Practice | Description |

|---|---|

| Wear Protective Gear | Always protect your eyes and hands. |

| Keep Area Clean | No one likes tripping over tools! |

| Use Circuit Breakers | A great way to handle those pesky shocks! |

Stay aware, follow these steps, and you’ll be a lathe wiring hero in no time!

Troubleshooting Lathe Wiring Issues

Common wiring problems and diagnosis techniques. Solutions for effective repairs and maintenance.Wiring issues can make a lathe machine feel like a stubborn mule. Common problems include loose connections, damaged wires, and blown fuses. Diagnosing these issues often involves checking for broken wires and ensuring everything is plugged in. To solve these problems, start with a thorough inspection. Always remember to switch off the power before poking around! Regular maintenance keeps your lathe happy, and a happy lathe means more successful projects!

| Problem | Possible Cause | Solution |

|---|---|---|

| Machine won’t start | Loose wiring | Tighten connections |

| Unexpected shut-offs | Blown fuse | Replace the fuse |

| Inconsistent power | Damaged wires | Inspect and replace wires |

Repairing these issues helps your lathe work like a dream, turning metal into wonders. Remember, a happy lathe equals a happy user!

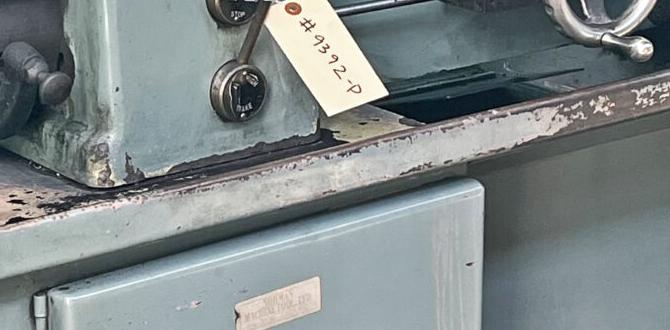

Upgrading Your Lathe Wiring System

Benefits of upgrading wiring systems in older lathes. Recommended materials and technologies for upgrades.Upgrading your lathe’s wiring is like giving your old friend a brand-new pair of shoes. It boosts performance and adds safety. New wiring can prevent shocks and short circuits, keeping your workspace as safe as a bubblewrap factory. For this upgrade, use high-quality copper wire and sturdy connectors. They last longer than your grandma’s secret cookie recipe!

| Material | Benefits |

|---|---|

| Copper Wire | Excellent conductivity, reduced heat |

| Heat-Resistant Insulation | Prevents wear, safe for high temps |

| Reliable Connectors | Stronger connection, less chance of failure |

With these upgrades, you’ll turn your old metal lathe into a shiny new marvel. And who knows? Your lathe might even start showing off! Upgrade wisely; your future projects will thank you!

Best Practices for Efficient Lathe Wiring

Tips for optimal wiring layout to improve efficiency. Maintenance practices to ensure longevity of wiring systems.Wiring your lathe can be a fun puzzle. To make it efficient, keep wires neat and tidy. Use color-coded cables to avoid confusion. Also, a good layout helps reduce clutter. While working, check wires often for any wear and tear. Clean them to keep dust away. Remember, a happy wire lives longer! Here’s a simple table for quick tips:

| Tip | Description |

|---|---|

| Neat Layout | Organize wires to avoid tangles. |

| Color-Coding | Use colors to identify different wires easily. |

| Regular Checks | Inspect wires for cracks or cuts. |

| Keep Clean | Dust off wires to avoid issues. |

Conclusion

In summary, lathe wiring for metal lathes is crucial for safety and efficiency. CAD design helps you visualize and plan your projects better. By understanding these concepts, you can create more precise and effective designs. To improve your skills, consider exploring tutorials on lathe wiring and CAD software. Let’s keep learning and making amazing things together!FAQs

Here Are Five Related Questions On The Topic Of Lathe Wiring For Metal Lathes And Cad Design:Sure! When we talk about lathe wiring, we’re discussing how to connect wires to a metal lathe. This helps the machine work correctly. CAD design means using a computer to create drawings for machines. You can plan and improve designs easily with CAD. It’s like drawing on paper, but on a screen!

Sure! Please go ahead and ask your question, and I’ll answer it in a simple way for you.

What Are The Essential Electrical Components Needed For Wiring A Metal Lathe, And How Do They Interact With The Machine’S Motor And Controls?To wire a metal lathe, you need a power supply, a switch, and a motor controller. The power supply gives electricity to the lathe. The switch lets you turn the machine on and off easily. The motor controller controls how fast the motor spins. Together, these parts help the lathe run smoothly and let you adjust its speed.

How Can Cad Software Be Utilized To Design The Layout Of Wiring For A Metal Lathe, Including The Placement Of Electrical Components And Connections?You can use CAD software to plan where to put wires and electrical parts for a metal lathe. First, draw the lathe’s shape on the computer. Then, decide where to place things like switches and motors. Next, connect the parts with lines to show how the wires will run. This helps us see everything clearly before we start building.

What Safety Considerations Should Be Taken Into Account When Wiring A Metal Lathe To Prevent Electrical Hazards During Operation?When wiring a metal lathe, safety is very important. Always make sure the machine is plugged into a grounded outlet. This helps prevent electrical shocks. You should also check that the wires are not frayed or damaged. Finally, use proper tools and wear protective gear to stay safe while working.

How Do Different Wiring Configurations Affect The Performance And Efficiency Of A Metal Lathe, Particularly In Relation To Its Speed And Torque?Different wiring configurations help a metal lathe work better. They can change how fast the lathe spins and how much strength it uses. Some setups make the lathe run faster but might give less power. Others can boost the power, making it easier to cut tough metal, but they may run slower. So, picking the right wiring helps you get the best performance from the lathe!

What Best Practices Should Be Followed When Creating A Wiring Diagram For A Metal Lathe To Ensure Clarity And Ease Of Troubleshooting In The Future?To make a good wiring diagram for a metal lathe, you should use clear labels. Write down what each wire does, so it’s easy to understand. Use different colors for different wires. This helps you see mistakes quickly. Finally, keep your diagram neat to avoid confusion later.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Wiring For Metal Lathes And Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we talk about lathe wiring, we’re discussing how to connect wires to a metal lathe. This helps the machine work correctly. CAD design means using a computer to create drawings for machines. You can plan and improve designs easily with CAD. It’s like drawing on paper, but on a screen!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll answer it in a simple way for you.”}},{“@type”: “Question”,”name”: “What Are The Essential Electrical Components Needed For Wiring A Metal Lathe, And How Do They Interact With The Machine’S Motor And Controls? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need a power supply, a switch, and a motor controller. The power supply gives electricity to the lathe. The switch lets you turn the machine on and off easily. The motor controller controls how fast the motor spins. Together, these parts help the lathe run smoothly and let you adjust its speed.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design The Layout Of Wiring For A Metal Lathe, Including The Placement Of Electrical Components And Connections? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to plan where to put wires and electrical parts for a metal lathe. First, draw the lathe’s shape on the computer. Then, decide where to place things like switches and motors. Next, connect the parts with lines to show how the wires will run. This helps us see everything clearly before we start building.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Wiring A Metal Lathe To Prevent Electrical Hazards During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, safety is very important. Always make sure the machine is plugged into a grounded outlet. This helps prevent electrical shocks. You should also check that the wires are not frayed or damaged. Finally, use proper tools and wear protective gear to stay safe while working.”}},{“@type”: “Question”,”name”: “How Do Different Wiring Configurations Affect The Performance And Efficiency Of A Metal Lathe, Particularly In Relation To Its Speed And Torque? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different wiring configurations help a metal lathe work better. They can change how fast the lathe spins and how much strength it uses. Some setups make the lathe run faster but might give less power. Others can boost the power, making it easier to cut tough metal, but they may run slower. So, picking the right wiring helps you get the best performance from the lathe!”}},{“@type”: “Question”,”name”: “What Best Practices Should Be Followed When Creating A Wiring Diagram For A Metal Lathe To Ensure Clarity And Ease Of Troubleshooting In The Future? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a good wiring diagram for a metal lathe, you should use clear labels. Write down what each wire does, so it’s easy to understand. Use different colors for different wires. This helps you see mistakes quickly. Finally, keep your diagram neat to avoid confusion later.”}}]}