Have you ever wondered how a metal lathe works? It’s more than just a big machine. Many people find that a well-wired lathe is exciting and essential for precision projects. A lathe can shape metal into amazing forms, making it a favorite in workshops.

But what happens if something goes wrong? Imagine you’re deep into a project, and suddenly the lathe stops. This is where the foot brake comes in. It’s a key safety feature that lets you quickly stop the lathe when you need to. Have you ever thought about how a simple pedal could make such a big difference?

In this article, we’re diving into lathe wiring and the importance of the metal lathe foot brake. You’ll learn how these components work together and why they matter for safety and efficiency. So, stay with us! Your next big project might just depend on this knowledge.

Lathe Wiring: Setting Up Your Metal Lathe Foot Brake

Lathe Wiring and Metal Lathe Foot Brake

Understanding lathe wiring is crucial for safety and efficiency. A metal lathe foot brake helps operators stop the machine quickly. Did you know that properly wired brakes can prevent accidents? Proper connections can also extend the lathe’s lifespan. Make sure wires are secured and away from moving parts. Regular checks ensure the foot brake functions reliably. This knowledge empowers operators to work confidently and safely. Always prioritize safety when working with machinery!Tools and Materials Needed

Essential tools for wiring and installation. Recommended materials for safety and efficiency.To wire a lathe foot brake safely and effectively, you need the right tools and materials. Start with essential tools like wire strippers, screwdrivers, and a multimeter. These help with connecting and testing wires.

For safety and efficiency, choose materials like heat-shrink tubing, electrical tape, and sturdy wire. These protect wires from damage and help connections stay strong. Here’s a quick list:

- Wire strippers

- Screwdrivers

- Multimeter

- Heat-shrink tubing

- Electrical tape

What tools do you need for wiring a lathe foot brake?

Essential tools include wire strippers, screwdrivers, and a multimeter for testing connections.

Wiring Basics for Metal Lathes

Fundamental electrical concepts for lathe wiring. Common wiring configurations for metal lathes.Knowing the basics of wiring is important for operating a metal lathe. Start by understanding voltage, current, and resistance. These concepts help you connect your lathe safely. Common wiring setups include:

- Single-phase wiring for small lathes

- Three-phase wiring for larger models

- Control circuits for foot brakes and switches

Understanding these will help keep your lathe running smoothly and safely!

What are the key wiring configurations for metal lathes?

Common configurations include single-phase and three-phase wiring. Each setup serves different lathe sizes and power needs. This ensures the machine works efficiently and safely.

Implementing a Foot Brake System

Explanation of foot brake functionality. Benefits of adding a foot brake to your metal lathe.A foot brake system is like the superhero for your metal lathe. It gives you quick control to stop the machine with your foot, which is super handy! Imagine you’re working away, and suddenly need to pause; no more fumbling around! Adding this system helps in boosting safety and can save you from accidents. Plus, you can keep both hands on your project. Who wouldn’t want that? Here’s a quick look at some benefits:

| Benefits | Description |

|---|---|

| Increased Safety | Quickly stop the lathe to prevent mishaps. |

| Better Control | Keep hands free for precise work. |

| Time-Saving | Stop and start the lathe without delays. |

So, don’t miss out on adding a foot brake. It’s a little addition that can make a huge difference! Safety and efficiency? Yes, please!

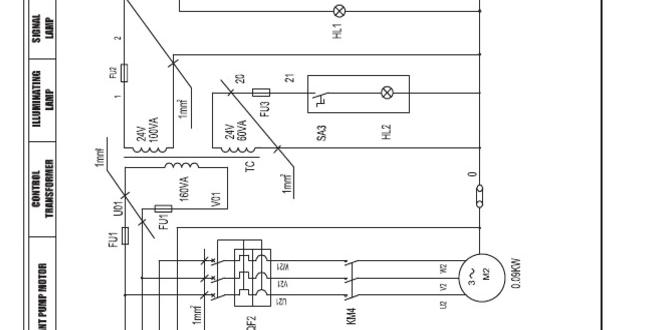

Step-by-Step Wiring Process

Detailed wiring instructions for the lathe. Visual aids and diagrams for clarity.Wiring a lathe can be simple if you follow clear steps. Start by reading the lathe’s manual. Make sure to plan your wiring layout. Use diagrams for guidance. They help you see how each wire connects. This can make your work easier and safer. Here’s how to do it:

- Gather all your tools and materials.

- Disconnect power before starting.

- Identify each wire by color.

- Connect the wires as shown in the diagram.

- Test the connections before use.

What are the steps for wiring a lathe?

First, you must connect the power supply to the motor. Ensure proper grounding for safety. Once connected, check all connections carefully. Finally, test the lathe before using it to avoid mistakes.Safety Precautions During Wiring

Important safety measures to take. Common hazards and how to avoid them.Wiring can be as tricky as trying to teach a cat to fetch. Safety comes first! Always wear gloves and goggles to keep yourself safe from sparks and tiny metal bits. Common hazards include electrical shocks and cuts, so stay alert. Make sure your workspace is tidy; a messy area is like a banana peel waiting to trip you up! Here’s a quick table of tips:

| Safety Measure | Why It Matters |

|---|---|

| Wear protective gear | Prevents injuries from sparks and cuts |

| Keep tools organized | Reduces the risk of accidents |

| Turn off power before starting | Avoids nasty electrical surprises |

By following these simple tips, you can work safely and with a smile, instead of a surprise scream!

Troubleshooting Common Wiring Issues

Identifying and resolving common wiring problems. Tips for maintaining electrical connections.Wiring problems can stop your metal lathe in its tracks. It’s important to find and fix these issues quickly. Check for loose wires or frayed connections. Good electrical connections keep everything running smoothly. Keep the wiring clean and dry. Regularly inspect the wiring to catch problems early.

- Look for signs of wear and tear.

- Ensure all connections are tight.

- Use electrical tape to cover exposed wires.

How can I troubleshoot wiring issues?

You can solve wiring issues by checking all the wires and connections. Make sure everything is secure. If you find damaged wires, replace them immediately to avoid bigger problems.

Advanced Wiring Techniques

Upgrading your lathe’s wiring for improved performance. Custom wiring options for unique setups.Want your lathe to work better? Upgrade its wiring! Good wiring can make a big difference in performance. You can also create custom wiring options for your special setup. This makes your lathe just as unique as you are. Think of it like giving your lathe a cool makeover!

| Upgrade Type | Benefit |

|---|---|

| Foot Brake Wiring | Safer stopping and better control! |

| Motor Wiring | Faster and smoother operation! |

It’s like giving your lathe a shot of espresso! Get ready for improved performance and a little fun while you work.

FAQs about Metal Lathe Wiring

Commonly asked questions and expert answers. Resources for further learning and troubleshooting.Many people have questions about metal lathe wiring. It’s important to understand how to safely use and maintain your metal lathe. Here are some common questions and expert answers:

What is a foot brake on a metal lathe?

A foot brake helps stop the lathe quickly and safely. It allows you to control the machine without using your hands.

What resources are available for learning more?

- Online tutorials offer step-by-step guides.

- Manuals provide essential information.

- Forums allow you to connect with other users.

These resources can help troubleshoot issues with wiring and improve your skills.

Conclusion

In summary, understanding lathe wiring and the metal lathe foot brake is essential for safety and efficiency. The foot brake helps you stop the machine quickly, preventing accidents. You should always check the wiring before use to ensure everything works properly. Explore more about lathe safety and maintenance to improve your skills and confidence in the workshop!FAQs

What Are The Basic Electrical Requirements For Wiring A Foot Brake For A Metal Lathe?To wire a foot brake for a metal lathe, you need a few things. First, get the right power supply, usually 110 or 220 volts. You’ll need heavy wire to handle the electricity safely. A switch will help you turn the brake on and off easily. Lastly, use proper connectors to join the wires together securely.

How Do You Properly Integrate A Foot Switch Into An Existing Metal Lathe Wiring System?To add a foot switch to your metal lathe, first, unplug the lathe. Then, find the power wires that connect to the lathe. Next, cut the power wire and connect one end to the foot switch. Finally, connect the other end from the foot switch back to the lathe, and plug everything back in. Now, you can turn the lathe on and off with your foot!

What Safety Considerations Should Be Taken Into Account When Wiring A Foot Brake For A Lathe?When wiring a foot brake for a lathe, always turn off the power first. Make sure wires are safe and neat. You should use the right type of wire to handle the power. Test the brake to ensure it works before you start the lathe. Keep your hands and clothes away from moving parts while you work.

Can A Foot Brake Be Added To An Older Model Metal Lathe, And What Modifications Are Necessary?Yes, you can add a foot brake to an older metal lathe. First, you need to find a foot pedal that fits. Then, connect the pedal to the lathe’s motor. You might have to change some wiring. Always remember to unplug the machine before making changes!

What Are Common Troubleshooting Steps For Issues With A Foot Brake On A Metal Lathe?If your foot brake on the metal lathe isn’t working, first check the connection. Make sure the wires are not loose or damaged. Next, see if the brake pedal feels stuck or doesn’t move freely. You can also look for any blockages or dirt around the brake area. Finally, test the brake again after making these checks.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Basic Electrical Requirements For Wiring A Foot Brake For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a foot brake for a metal lathe, you need a few things. First, get the right power supply, usually 110 or 220 volts. You’ll need heavy wire to handle the electricity safely. A switch will help you turn the brake on and off easily. Lastly, use proper connectors to join the wires together securely.”}},{“@type”: “Question”,”name”: “How Do You Properly Integrate A Foot Switch Into An Existing Metal Lathe Wiring System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To add a foot switch to your metal lathe, first, unplug the lathe. Then, find the power wires that connect to the lathe. Next, cut the power wire and connect one end to the foot switch. Finally, connect the other end from the foot switch back to the lathe, and plug everything back in. Now, you can turn the lathe on and off with your foot!”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Wiring A Foot Brake For A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a foot brake for a lathe, always turn off the power first. Make sure wires are safe and neat. You should use the right type of wire to handle the power. Test the brake to ensure it works before you start the lathe. Keep your hands and clothes away from moving parts while you work.”}},{“@type”: “Question”,”name”: “Can A Foot Brake Be Added To An Older Model Metal Lathe, And What Modifications Are Necessary? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can add a foot brake to an older metal lathe. First, you need to find a foot pedal that fits. Then, connect the pedal to the lathe’s motor. You might have to change some wiring. Always remember to unplug the machine before making changes!”}},{“@type”: “Question”,”name”: “What Are Common Troubleshooting Steps For Issues With A Foot Brake On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your foot brake on the metal lathe isn’t working, first check the connection. Make sure the wires are not loose or damaged. Next, see if the brake pedal feels stuck or doesn’t move freely. You can also look for any blockages or dirt around the brake area. Finally, test the brake again after making these checks.”}}]}