Do you love making things with your hands? Have you ever thought about how to use a metal lathe? The metal lathe is an amazing tool. It helps you shape metal into all sorts of things, from gears to beautiful pieces of art.

But what about the lathe wiring? This part might seem tricky at first. However, understanding the quill can make your lathe experience smooth. Imagine trying to work on a project, and the machine won’t start. Wouldn’t that be frustrating? That’s why good wiring is so important.

Here’s a fun fact for you: did you know that a metal lathe can spin at high speeds? This allows it to cut metal easily. But if the wiring isn’t correct, it can cause problems. In this article, we’ll explore how to wire your lathe correctly and understand the quill better. Get ready to become a pro with your lathe!

Lathe Wiring: Understanding Metal Lathe Quill Connections When It Comes To Operating A Metal Lathe, Understanding The Wiring And Electrical Connections, Especially For The Quill, Is Essential For Ensuring Precision And Safety. Metal Lathes Are Indispensable Tools In Machining, Offering Incredible Versatility For Various Tasks. The Quill, A Key Component In Many Lathes, Allows For Adjustments In Depth And Position, Making It Critical To Properly Wire And Maintain For Optimal Performance. Importance Of Proper Lathe Wiring Proper Lathe Wiring Not Only Influences The Lathe’S Functionality But Also Plays A Crucial Role In Safety. Malfunctioning Electrical Connections Can Lead To Equipment Failure Or Accidents, Making It Imperative For Operators To Ensure All Parts, Including The Quill, Are Correctly Wired. Understanding The Electrical Layout And Connection Points Can Prevent Mishaps And Prolong The Machine’S Lifespan. Components Of Metal Lathe Wiring 1. **Power Supply**: Provides The Necessary Voltage For The Lathe To Function. 2. **Motor Connections**: Connects Directly To The Drive Mechanism, Allowing For Speed And Torque Adjustments. 3. **Quill Wiring**: Responsible For The Operation Of The Quill, Which Controls The Tool’S Vertical Movement. 4. **Safety Switches**: Emergency Cut-Off Switches That Enhance Safety During Operation. Wiring The Quill: Step-By-Step Guide 1. **Disconnect Power**: Before Starting Any Wiring, Ensure That The Lathe Is Unplugged To Prevent Electrical Shock. 2. **Access The Quill Mechanism**: Remove Any Covers Or Panels That Obstruct Access To The Quill’S Wiring Connection. 3. **Identify Wire Specifications**: Refer To The Manufacturer’S Manual For The Specific Wiring Diagram For Your Metal Lathe Model. 4. **Make Connections**: Carefully Connect The Wires As Illustrated In The Wiring Diagram. Double-Check Connections For Security. 5. **Test Functionality**: With Everything Reassembled And Power Restored, Conduct A Test To Ensure The Quill Operates Smoothly. Troubleshooting Common Issues If The Quill Does Not Function As Expected: – **Check Connections**: Ensure All Wiring Is Intact And Securely Connected. – **Inspect For Damage**: Look For Any Frayed Wires Or Components That May Be Affecting Performance. – **Consult The Manual**: The Troubleshooting Section Of Your Lathe’S Manual May Provide Specific Guidance Related To Wiring Issues. Conclusion Understanding Lathe Wiring, Particularly For The Metal Lathe Quill, Is Vital For Any Machinist Looking To Maximize Their Equipment’S Performance. With Proper Wiring, Regular Maintenance, And A Keen Eye On Safety, Operators Can Enjoy Enhanced Machining Capabilities And Longevity From Their Lathes. Always Refer To The Specific Device’S Manual When In Doubt And Prioritize Safety Throughout The Process.

Lathe Wiring and Metal Lathe Quills

Are you fascinated by how machines work? Understanding lathe wiring can help you see the magic behind a metal lathe. The quill is an important part of the lathe. It holds the cutting tool and moves it smoothly. Proper wiring ensures the lathe operates safely and efficiently. Did you know that messy wiring can lead to machine failure? Learning about lathe wiring and quills makes working with metal easier and more fun!Understanding the Metal Lathe Quill

Definition and function of a quill in a metal lathe.. Importance of proper quill wiring for operational efficiency..A quill in a metal lathe is like a trusty sidekick. It holds the cutting tool snugly and helps shape metal with precision. Think of it as the superhero that keeps everything on track! Proper wiring of the quill is crucial. It ensures smooth operation and can save you from clunky mess ups. Remember, a well-wired quill works like a charm, while a poorly connected one is just asking for trouble.

| Quill Function | Wiring Importance |

|---|---|

| Holds cutting tools | Smooth operation |

| Shapes metal accurately | Prevents damage |

| Enhances precision | Improves efficiency |

Components of Quill Wiring

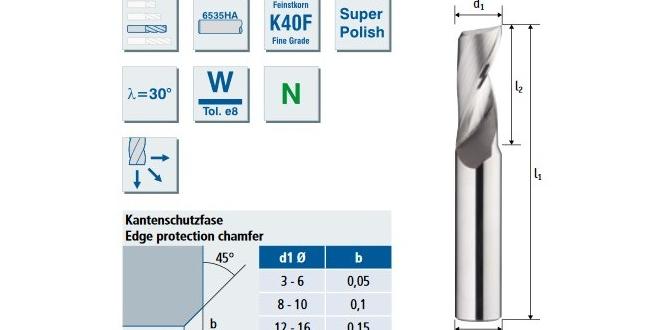

Breakdown of essential wiring components needed for a metal lathe quill.. Explanation of electrical specifications and requirements..The quill wiring in a metal lathe has important parts. Each part plays a specific role. Here are key components:

- Power Supply: Provides electricity to the lathe.

- Wires: Carry current to different machine parts.

- Switches: Turn the power on and off.

- Connectors: Join wires together safely.

- Fuses: Protect against too much current.

Understanding these parts helps keep your lathe running smoothly. Each component must meet specific electrical requirements. This includes proper voltage and current ratings to avoid damage. Knowing these details ensures your metal lathe quill functions at its best.

What are the key specifications for lathe wiring?

Key specifications for lathe wiring include voltage ratings of 120V or 240V and a current capacity of 10-20 Amps. Ensure all components match these specifications for safety and efficiency.

Wiring Diagrams for Metal Lathe Quills

Visual guides on wiring layouts for different types of lathes.. Stepbystep instructions for reading and interpreting wiring diagrams..Wiring diagrams help you understand how to connect a metal lathe quill. They show a visual layout of wires and parts. Different lathes may have unique wiring. Follow these steps to read diagrams:

- Look for labels on wires and connections.

- Identify the power source and its connection points.

- Check for color coding to match wires.

- Follow arrows or lines to see the flow of electricity.

With practice, you can become skilled at using these diagrams to wire your metal lathe quill safely and correctly!

Why are wiring diagrams important for lathes?

Wiring diagrams are crucial for ensuring proper connections and safety in lathes. They prevent mistakes that could cause damage or accidents.

Key benefits of using wiring diagrams:

- Easy troubleshooting.

- Clear guidance for installation.

- Improved safety during use.

Tools Required for Wiring a Metal Lathe Quill

List of essential tools needed for the wiring process.. Tips on selecting the right tools for optimal performance..For wiring a metal lathe quill, you’ll need some key tools. A wiring diagram is a must-have to avoid confusion. Grab some quality wire cutters and strippers for the crispy job ahead. A good pair of pliers helps with tight spots. Don’t forget your trusty screwdriver set, because bolts need love too! Lastly, an insulation tester ensures safety. Choose tools that feel comfy and right in your hand, like picking your favorite snack! Remember, the right tools can turn a messy job into a masterpiece.

| Tool | Purpose |

|---|---|

| Wiring Diagram | Guidance for connections |

| Wire Cutters | Trimming wires |

| Wire Strippers | Removing insulation |

| Pliers | Gripping and twisting |

| Screwdriver Set | Tightening screws |

| Insulation Tester | Ensuring safety |

Step-by-Step Wiring Process

Detailed instructions on wiring a metal lathe quill from start to finish.. Safety precautions to take during the wiring process..Wiring a metal lathe quill sounds tricky, but it can be a fun puzzle. First, gather the right tools, like wire strippers and a screwdriver. Then, follow these simple steps:

| Step | Action |

|---|---|

| 1 | Turn off the power supply. Safety first, or you might make a funny hairstyle with your hair all frizzy! |

| 2 | Strip the wires carefully. Think of it as giving them a little haircut. |

| 3 | Connect the wires to the quill. Match the colors like a scavenger hunt. |

| 4 | Secure the connections with tape. Pretend you’re wrapping a present! |

| 5 | Power it on and test it out. Time to show off your handiwork! |

While doing this, remember to wear gloves and goggles. You don’t want any electrical surprises! Follow these steps, and you’ll be a wiring wizard before you know it.

Troubleshooting Wiring Issues

Common problems encountered with lathe quill wiring and their solutions.. Diagnostic tips to identify issues effectively..Troubleshooting lathe quill wiring can seem tricky, but it’s actually like solving a fun puzzle! Common issues include loose connections or short circuits. These problems can make your lathe act like a cranky cat—no one likes that!

Here’s a quick guide to find those pesky problems:

| Problem | Possible Cause | Solution |

|---|---|---|

| Lathe won’t start | Disconnected wires | Check all connections |

| Unusual noises | Frayed wires | Inspect for damage |

| Intermittent function | Loose terminals | Tighten connections |

To diagnose issues effectively, check wires for tightness and look for wear and tear. Remember, a little investigation can save your lathe from acting up and make your projects go smoothly. Plus, you might even impress your friends with your detective skills!

Maintenance Tips for Quill Wiring

Best practices for maintaining and caring for metal lathe quill wiring.. Signs that wiring needs to be checked or replaced..Keeping your metal lathe quill wiring in tip-top shape is a bit like pampering a pet! First, always check for loose connections. If the wiring looks frayed or discolored, it’s time for a makeover. A good rule is to inspect it every few months. If your lathe starts to make strange noises, or if the quill moves unevenly, it’s a sign to take a closer look. Remember, a happy lathe means happy turning!

| Signs to Check Wiring | Action Needed |

|---|---|

| Frayed or discolored wiring | Replace immediately! |

| Strange noises | Investigate promptly! |

| Uneven quill movement | Check connections! |

Advanced Wiring Techniques

Exploration of advanced wiring methods for enhanced performance.. Recommendations for upgrades and modifications to existing wiring setups..Exploring advanced wiring methods can boost your metal lathe’s performance. Think of it like giving your tool a turbo boost! Simple upgrades can make a big difference. For example, replacing old wires with higher gauge options helps with efficiency. You can even add a quill switch for easier control. Don’t forget, neat wiring is happy wiring! Here’s a quick table to summarize some nifty upgrades:

| Upgrade | Benefit |

|---|---|

| Higher Gauge Wires | Improved efficiency |

| Quill Switch | Better control |

| Connector Kits | Safer connections |

These suggestions aren’t just hot air; they can really help your lathe run smoother! So, let’s get our wires crossed in the best way possible!

Conclusion

In summary, understanding lathe wiring and the metal lathe quill helps you improve your projects. The quill adjusts tool depth and enhances precision. Always ensure proper wiring for safety and efficiency. If you’re keen to learn more, consider exploring guides or tutorials on lathe operation. With practice, you’ll become more skilled in using your metal lathe!FAQs

Here Are Five Related Questions On The Topic Of Lathe Wiring And Specifically Focusing On Metal Lathe Quills:Sure! A metal lathe is a machine that helps shape metal parts. The quill is a part of the lathe that holds tools. It moves in and out to cut metal. To make it work, we need to wire it correctly. This means connecting the right wires so the parts can move safely. Always ask an adult for help with wiring to stay safe!

Sure! Please tell me the question you would like me to answer.

What Are The Essential Components Of The Wiring System For A Metal Lathe Quill?The wiring system for a metal lathe quill has a few key parts. First, there are wires that connect to power. These wires help the quill move up and down. Next, there are switches that let you control the movement. Finally, connectors link everything together, making sure it works smoothly.

How Do You Troubleshoot Electrical Issues Related To The Quill Drive Motor Of A Metal Lathe?To troubleshoot the quill drive motor, you first check the power supply. Make sure it’s plugged in and turned on. Next, look for any loose or damaged wires. You can also test the motor with a multimeter to see if it works. If it’s still not running, you may need to ask an adult for help.

What Safety Precautions Should Be Taken When Wiring Or Repairing The Electrical Components Of A Metal Lathe Quill?When working on electrical parts of a metal lathe, you should always turn off the power first. Wear rubber gloves to protect your hands. Make sure the area is dry to avoid shocks. Use tools with rubber handles to keep yourself safe. Finally, if you’re unsure, ask an adult for help.

Can You Explain The Function Of Limit Switches In The Quill Assembly Of A Metal Lathe?Limit switches are small devices in the quill assembly of a metal lathe. They help control how far the quill can move up or down. When the quill reaches a certain point, the limit switch sends a signal to stop the machine. This keeps the lathe safe and helps prevent damage. You can think of them like reminders that tell the machine when to stop.

How Does The Wiring Of A Metal Lathe Quill Differ From That Of Other Types Of Machine Tools?The wiring of a metal lathe quill connects to a motor that helps it move. This is different from other machines, where the wiring might control different actions, like cutting or drilling. In a lathe, the quill needs precise control to shape metal. It uses fewer wires but needs to be very accurate. This helps make sure the metal is cut smoothly and evenly.