Understanding Lathe Wiring: Metal Lathe Wiring Diagram Explained

Understanding Lathe Wiring and Diagrams

Wiring a metal lathe needs careful attention to detail. A proper lathe wiring diagram shows how to connect wires safely and correctly. Did you know incorrect wiring can lead to equipment failure or worse? You learn about different components like switches, motors, and power sources in these diagrams. This knowledge can help hobbyists and professionals ensure their lathes run smoothly and safely. A well-drawn diagram can be your best friend in avoiding errors!Importance of Proper Lathe Wiring

Discuss the safety implications of incorrect wiring.. Outline the impact of proper wiring on lathe performance and longevity..Connecting wires the right way is important, much like putting on your shoes before heading outside! Incorrect wiring can lead to safety mishaps like electric shocks or machine fires. Yikes! On the flip side, proper wiring helps your lathe work smoothly, boosting performance and making it last longer. Think of it as giving your lathe a cozy home. A well-wired lathe can run 20% longer without hiccups compared to a poorly wired one. That’s a win-win!

| Impact of Wiring | Consequences of Incorrect Wiring |

|---|---|

| Increased Performance | Electric Shock |

| Longer Lifespan | Machine Fires |

| Fewer Repairs | Damage to Tools |

Understanding Metal Lathe Components

Identify key components of a metal lathe relevant to wiring.. Explain the function of each component in the context of electrical systems..Understanding a metal lathe means knowing its parts. Here are key components that relate to wiring:

- Motor: Powers the lathe, converting electricity to movement.

- On/Off Switch: Controls the machine’s power supply, ensuring safety.

- Wiring: Connects all components, carrying electricity where needed.

- Control Panel: Allows users to adjust settings easily.

- Emergency Stop Button: Quickly halts the lathe in emergencies, protecting users.

Each part plays a vital role in making the lathe work smoothly. Knowing these helps in understanding how to wire the machine correctly.

What are the key components of a metal lathe?

The key components of a metal lathe include the motor, switches, and wiring. These parts work together to help shape metal accurately.

Basic Principles of Lathe Wiring

Introduce electrical concepts relevant to lathe wiring (voltage, amperage, etc.).. Explain the significance of grounding and circuit protection..Understanding electricity helps in lathe wiring. Two main concepts are voltage and amperage. Voltage is the push that moves electricity. Amperage is how much electricity flows. They work together for machines to run well. Grounding is very important, too. It keeps everything safe by directing electricity away from people. Circuit protection, like fuses or breakers, stops overloads, preventing fires. These steps ensure a safe workspace.

What is the importance of grounding in lathe wiring?

Grounding protects people from electric shock. It creates a safe path for electricity to flow. This makes lathes safer to use.

Common Wiring Configurations

Detail the typical wiring layouts found in metal lathes.. Compare singlephase vs. threephase wiring setups..Metal lathes often have different wiring designs that suit their specific needs. Single-phase wiring is common for smaller lathes and is usually simpler to install. It’s like using a simple extension cord. In contrast, three-phase wiring is more powerful and is great for larger machines, handling big tasks like a superhero! Here’s a quick glance at the differences:

| Wiring Type | Power | Installation |

|---|---|---|

| Single Phase | Lower | Easy |

| Three Phase | Higher | More Complex |

In short, choose single-phase for home projects and three-phase for serious work! Just remember, one is like pizza, and the other is like an all-you-can-eat buffet. Both delicious, but totally different experiences!

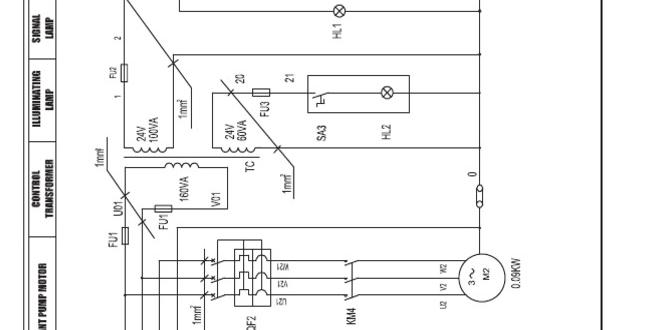

Interpreting Metal Lathe Wiring Diagrams

Provide guidance on how to read wiring diagrams.. Highlight common symbols and notations used in diagrams..Reading wiring diagrams can be fun! These diagrams show how everything connects in a metal lathe. Key symbols help us understand the parts. Here are some common symbols:

- Lines: Show wires connecting parts.

- Dots: Represent connection points.

- Arrows: Indicate the direction of power flow.

- Boxes: Often show components like motors or switches.

Start by locating symbols. Then, trace the lines to see how parts are linked. This way, you understand your machine better!

Why are symbols important in wiring diagrams?

Symbols are crucial because they help users quickly understand the connections and functions of different parts. Each symbol represents something specific, making it easier to follow the diagram without confusion.

Step-by-Step Wiring Process for Metal Lathes

Outline a detailed approach to wiring a metal lathe from scratch.. Include safety precautions and tools required..Wiring a metal lathe starts with safety. Always wear gloves and goggles. Here’s a simple approach:

- Gather tools like screwdrivers, wire strippers, and wire connectors.

- Read the wiring manual carefully to avoid mistakes.

- Connect the power supply first, then link the motor wires.

- Ensure all connections are snug and check for loose wires.

- Finally, test the lathe before full use to confirm proper wiring.

Following these steps ensures safe and successful wiring. Remember, safety first!

How to start wiring for beginners?

Begin with properly identifying wires and their connections. Always refer to the lathe’s wiring diagram for guidance.

Troubleshooting Wiring Issues

Identify common wiring problems encountered with metal lathes.. Offer solutions for diagnosing and fixing wiringrelated issues..Troubleshooting wiring issues can be a bit like finding a needle in a haystack, especially with metal lathes. Common problems include loose connections, frayed wires, or blown fuses. To diagnose these issues, first check your connections—if they look like a spaghetti factory exploded, it’s time to tidy up! For frayed wires, a quick trim and some electrical tape can work wonders. Got a blown fuse? It might be time to channel your inner electrician and replace it. Here’s a handy table to help you remember the fixes:

| Problem | Solution |

|---|---|

| Loose Connections | Check and tighten all connections. |

| Frayed Wires | Trim and tape them up. |

| Blown Fuse | Replace it with a new one. |

Remember, safety first! Always unplug your lathe before diving into any wiring repairs. Happy tinkering!

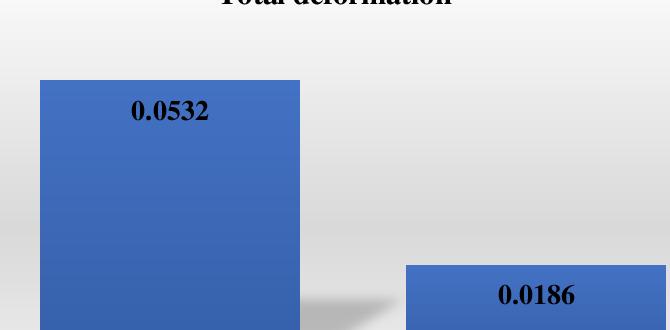

Upgrading Lathe Wiring for Enhanced Performance

Discuss modern wiring options that can improve lathe efficiency.. Provide tips for recognizing when an upgrade is necessary..Updating your lathe wiring can make your machine run smoother and snappier, just like a well-oiled mustang! Modern wiring options, like high-quality connectors and insulated cables, boost efficiency. Look for signs like frequent tripping switches or weird noises. If your lathe starts acting like it’s possessed, it may be time for an upgrade. Check out the comparison in the table below for the best wiring choices!

| Wiring Type | Benefits |

|---|---|

| High-Quality Connectors | Better electrical contact and durability |

| Insulated Cables | Reduce energy loss and increase safety |

| Upgraded Circuit Breakers | Prevent overload and protect your machinery |

Resources for Further Learning

Suggest additional readings and online resources for wire schematics.. List professional organizations or forums related to metal lathe wiring..There are many resources to help you learn more about wiring metal lathes. Books and websites can show you clear diagrams and wiring tips. Check out helpful forums where professionals share their knowledge. Here are some good suggestions:

- Books on machine wiring

- Online articles about lathe wiring

- Forums like The Home Machinist

- Professional organizations in machining

Exploring different sources will deepen your understanding. You can learn quickly with the right tools and support!

What are some good online resources for schematics?

Many websites offer excellent schematics for metal lathe wiring. Look for sites with **detailed diagrams** and **step-by-step guides**. They can make wiring easier to understand.

Conclusion

In summary, understanding lathe wiring is crucial for safe operation. A wiring diagram helps you connect the electrical components correctly. Make sure to follow the diagram step-by-step. If you’re unsure, seek help from a professional. We encourage you to read more about lathe wiring to enhance your skills and keep your projects running smoothly!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Wiring Diagrams:Sure! Here are some questions about lathe wiring. A lathe is a tool that helps shape metal. It uses electricity to work. Wiring diagrams show how to connect wires safely. Learning this can help you use a lathe properly and keep it running well.

Sure! Please ask me a question, and I’ll be happy to help you.

What Are The Essential Components To Include In A Metal Lathe Wiring Diagram?In a metal lathe wiring diagram, you need to include the power source, switches, and motor. Show how wires connect everything together. It’s also important to show any safety features. You can use labels to help everyone understand what each part does. This makes it easier for us to fix or use the lathe later.

How Do You Determine The Appropriate Power Supply Requirements For A Metal Lathe?To find the right power supply for a metal lathe, you first need to know how much power the lathe needs. This is usually measured in watts. You can check the lathe’s manual or label for this information. Then, make sure your power supply can give at least that much power. It’s also good to have a little extra power just in case.

What Safety Precautions Should Be Taken When Wiring A Metal Lathe?When wiring a metal lathe, you should always turn off the power first. Use insulated tools to keep yourself safe from electric shock. Make sure your hands are dry and wear safety glasses. Check the wires to ensure they are not damaged. Finally, ask an adult for help if you’re unsure about anything.

Can You Explain The Function Of Each Wire Color Commonly Used In Metal Lathe Wiring?Sure! In metal lathe wiring, we usually see three colors: black, white, and green. The black wire is for power, which means it carries electricity to the machine. The white wire is for neutral, helping to complete the circuit. The green wire is for safety; it connects to the ground to prevent shocks. Always remember to be careful when working with wires!

Where Can I Find Specific Wiring Diagrams For Different Models Of Metal Lathes?You can find wiring diagrams for metal lathes in a few places. Start by checking the user manual that came with your lathe. You can also visit the manufacturer’s website for your specific model. Another good place is online forums where other users share tips and diagrams. Don’t forget to ask your local hardware store, as they may have resources, too!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about lathe wiring. A lathe is a tool that helps shape metal. It uses electricity to work. Wiring diagrams show how to connect wires safely. Learning this can help you use a lathe properly and keep it running well.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask me a question, and I’ll be happy to help you.”}},{“@type”: “Question”,”name”: “What Are The Essential Components To Include In A Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe wiring diagram, you need to include the power source, switches, and motor. Show how wires connect everything together. It’s also important to show any safety features. You can use labels to help everyone understand what each part does. This makes it easier for us to fix or use the lathe later.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Power Supply Requirements For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right power supply for a metal lathe, you first need to know how much power the lathe needs. This is usually measured in watts. You can check the lathe’s manual or label for this information. Then, make sure your power supply can give at least that much power. It’s also good to have a little extra power just in case.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, you should always turn off the power first. Use insulated tools to keep yourself safe from electric shock. Make sure your hands are dry and wear safety glasses. Check the wires to ensure they are not damaged. Finally, ask an adult for help if you’re unsure about anything.”}},{“@type”: “Question”,”name”: “Can You Explain The Function Of Each Wire Color Commonly Used In Metal Lathe Wiring?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! In metal lathe wiring, we usually see three colors: black, white, and green. The black wire is for power, which means it carries electricity to the machine. The white wire is for neutral, helping to complete the circuit. The green wire is for safety; it connects to the ground to prevent shocks. Always remember to be careful when working with wires!”}},{“@type”: “Question”,”name”: “Where Can I Find Specific Wiring Diagrams For Different Models Of Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find wiring diagrams for metal lathes in a few places. Start by checking the user manual that came with your lathe. You can also visit the manufacturer’s website for your specific model. Another good place is online forums where other users share tips and diagrams. Don’t forget to ask your local hardware store, as they may have resources, too!”}}]}