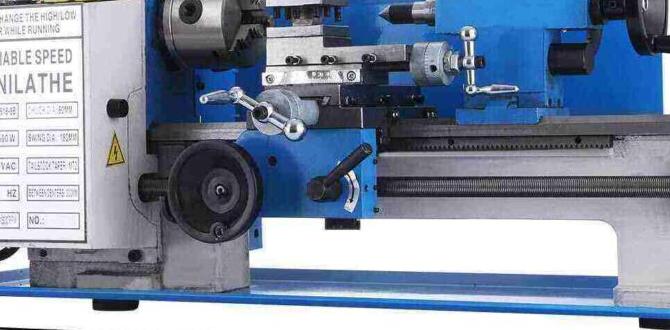

Have you ever watched a lathe spin and wondered how it works? A lathe is a fantastic tool that shapes metal into amazing objects. But did you know that one of the biggest challenges in lathe work is finding the right workholding? Many people think workholding has to be expensive, but that isn’t true. You can achieve great results with cheap metal lathe solutions!

Imagine creating a custom part for a project. You have your metal, but how do you hold it steady? With the right techniques and affordable workholding options, you can turn your ideas into reality without breaking the bank.

In this article, we’ll explore some clever ways to hold your metal while using low-cost lathe setups. You’ll learn with simple tips and tricks. Let’s dive into the world of lathe workholding! Who knows what amazing creations you might make?

Lathe Workholding For A Cheap Metal Lathe: Tips & Techniques

Affordable Lathe Workholding Solutions

Using a cheap metal lathe can be a game-changer for hobbyists and seasoned machinists alike. Did you know that workholding is key to successful lathe projects? Finding budget-friendly options can save money while maintaining quality. You can use simple clamps and fixtures to securely hold materials. This way, you achieve better precision and reduce errors. Working on a tight budget doesn’t mean sacrificing results. Embrace creativity and explore cost-effective workholding techniques to enhance your projects!Understanding Workholding in Metal Lathes

Definition and importance of workholding in lathe operations. Types of workholding systems used in metal lathes.Workholding in metal lathes is about holding materials securely while they are shaped. It is very important because it ensures accurate cuts and prevents accidents. There are different types of systems used for workholding:

- Chucks: These grip the material tightly.

- Vises: They hold flat pieces in place for easy access.

- Collets: They are good for holding round objects tightly.

Each type of system helps make lathe work smoother and safer. Choosing the right one can improve results and make tasks easier.

What are the types of workholding systems in metal lathes?

There are three main types: chucks, vises, and collets.Why is workholding important?

It keeps materials stable and ensures safety during machining.Factors to Consider When Choosing a Cheap Metal Lathe

Key specifications and features of a good lathe. Importance of durability and stability in lathe workholding.Choosing a cheap metal lathe involves knowing certain key features. A good lathe should have a strong motor and precise controls. These specs allow for smoother operation and better results. Durability is essential too. A stable lathe will not wobble, ensuring consistent work. Always consider the material used in its construction. Metal is preferable for longevity and strength. Remember, a solid base makes all the difference in your projects.

What should I look for in a metal lathe?

Look for power, precision, and stability in your metal lathe. These features will help you work better and last longer.

DIY Workholding Solutions for Metal Lathes

Stepbystep guide to creating your own workholding devices. Benefits of customization and practicality in a DIY approach.Creating your own workholding devices for metal lathes can be fun and useful. Start by gathering materials like wood or scrap metal. Cut them into pieces and assemble them based on your needs. The best part? You can customize it to fit any project! This DIY approach saves money and lets you add a personal touch. Plus, your machine will never look as stylish as with a DIY holder! Here’s a quick look at some popular solutions:

| Device Type | Material | Benefits |

|---|---|---|

| Wooden Vise | Wood | Flexible and adjustable |

| Magnetic Holder | Metal | Strong grip and easy to use |

| Clamp Blocks | Scrap metal | Inexpensive and versatile |

So, roll up your sleeves and show your lathe some love! Remember, the best creative solutions often come from a little DIY magic.

Where to Find Cheap Metal Lathe Workholding Accessories

Best online and physical stores for budget options. Tips for finding deals, discounts, and secondhand equipment.Finding affordable metal lathe workholding accessories can be fun! Start your search online at places like Amazon, eBay, or specialized tool shops. Often, they have discounts that make your wallet feel like it’s on a diet. For physical stores, check out local hardware stores or tool auctions. Don’t forget to look for secondhand deals—sometimes, treasures hide in the secondhand section! You never know what gems you might discover!

| Store Type | Where to Look | Extra Tips |

|---|---|---|

| Online Retailers | Amazon, eBay | Look for daily deals! |

| Physical Stores | Local hardware stores | Check for clearance sections! |

| Secondhand Equipment | Garage sales, thrift stores | Ask around in your network! |

Remember, a little patience can lead to great finds! Happy hunting!

Maintenance Tips for Longevity of Workholding Devices

Essential maintenance practices to extend the life of workholding tools. Signs that indicate when to replace or repair workholding accessories.To keep your workholding devices in great shape, follow some simple maintenance practices. Clean them regularly and check for wear. Lubricate moving parts to ensure they work smoothly. Replace worn components as needed. Notice any unusual sounds or movements? These could mean it’s time for a repair or replacement. Being proactive helps you save money and extends the life of your tools.

What are signs that workholding accessories need replacement or repair?

Watch for these signs:

- Cracks or chips in the material.

- Loose or wobbly parts during operation.

- Unusual noises during use.

Taking action early can prevent bigger problems later!

Common Issues with Cheap Metal Lathe Workholding and How to Troubleshoot Them

Typical problems encountered with budget workholding solutions. Effective troubleshooting tips and techniques to resolve these issues.If you’re using a budget lathe, you might face some common hiccups. Often, workholding solutions may not grip your materials well. This can lead to slips that make projects go awry. Yikes! What can you do? First, check that everything is tight and aligned. If it’s loose, it’s like trying to hold an ice cream cone in a rainstorm—messy and frustrating!

| Issue | Solution |

|---|---|

| Poor Grip | Ensure clamps and chucks are secure. Tighten them properly. |

| Vibration | Balance your workpiece to minimize wobbling. |

| Inaccurate Cuts | Adjust your tool settings and check alignment. |

By focusing on these basics, you can turn your lathe into a reliable partner—like a trusty dog, not a chewed-up shoe! Happy turning!

Customer Reviews and Recommendations

Insights from users on affordability versus quality in workholding. Highlighting toprated cheap workholding solutions based on user feedback.Users often shine a light on the balance between affordability and quality in workholding. Many agree that good workholding doesn’t need to break the bank. Happy customers recommend several top-rated budget choices, proving that cheap can also be reliable! Read on for the best options based on user buzz. You might find your next favorite tool right here!

| Product | Price | User Rating |

|---|---|---|

| Budget Clamp Set | $25 | 4.7/5 |

| Alloy Quick-Change Workholding | $40 | 4.5/5 |

| Heavy-Duty Vise | $60 | 4.8/5 |

Conclusion

In summary, using a cheap metal lathe can be a great way to start lathe workholding. Remember to choose the right tools and setups for your projects. You can create amazing things without spending a lot. Explore online resources or tutorials to learn more. Let’s dive into the world of machining and get hands-on with your new skills!FAQs

Certainly! Here Are Five Questions Related To Workholding For A Cheap Metal Lathe:Sure! Here are five questions about using a cheap metal lathe for workholding: 1. What is workholding? Workholding is how we hold a piece of metal while we shape it in the lathe. 2. Why do I need clamps? Clamps keep the metal steady. This helps us make precise cuts without moving it. 3. Can I use a chuck? Yes! A chuck grips the metal tightly. It allows us to turn it easily while we work. 4. How do I choose the right size? You should choose clamps or chucks that fit your metal piece. The right size helps it stay secure. 5. What if I don’t have tools? You can use strong tape or rubber bands in a pinch. But it’s better to use proper tools for safety.

Sure! Please ask me a question from the section you’d like me to answer.

What Are The Best Affordable Workholding Solutions For Securing Parts On A Budget-Friendly Metal Lathe?You can use a few simple tools to hold parts on a budget-friendly metal lathe. A vise is a great choice because it can grip your work tightly. You can also use clamps to hold down your pieces. For small parts, make wooden or plastic jigs. These options are cheap and work well to keep your parts secure while you work.

How Can I Enhance The Stability Of My Workpieces When Using A Low-Cost Lathe Without Investing In Expensive Accessories?To make your workpieces more stable on a low-cost lathe, you can try some simple tricks. First, use a heavier base for your lathe, like a thick piece of wood, to stop it from shaking. You can also clamp your workpiece tightly in the chuck, which is the part that holds it. Another idea is to balance your workpiece better by cutting a bit from all sides, so it doesn’t wobble. Lastly, keep your hands steady while working to help make clean cuts.

What Diy Workholding Methods Can I Create Using Common Materials For My Inexpensive Metal Lathe?You can make simple workholding tools for your metal lathe using stuff you already have. First, you can use a wooden block to hold small pieces while you work. Just drill a hole in the block for the piece to fit in. Second, rubber bands can help grip items tightly. Lastly, you can use strong clamps to hold larger pieces in place while you turn them.

Are There Specific Types Of Chucks Or Fixtures That Are Particularly Effective For Workholding On Cheap Metal Lathes?Yes, some types of chucks and fixtures work well on cheap metal lathes. A three-jaw chuck holds round pieces tightly. A four-jaw chuck is better for odd shapes. You can also use a faceplate for flat pieces. These tools help keep your work steady and safe while you cut.

How Do I Properly Align And Secure My Workpiece In A Low-Cost Lathe To Achieve Accurate Machining Results?To align your workpiece in a low-cost lathe, first make sure it is clean. Place the piece in the center of the lathe. Use the tailstock to hold it tightly without squeezing too hard. Next, check if it spins straight by turning it slowly. If it wobbles, adjust until it is straight.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Workholding For A Cheap Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about using a cheap metal lathe for workholding: 1. What is workholding? Workholding is how we hold a piece of metal while we shape it in the lathe. 2. Why do I need clamps? Clamps keep the metal steady. This helps us make precise cuts without moving it. 3. Can I use a chuck? Yes! A chuck grips the metal tightly. It allows us to turn it easily while we work. 4. How do I choose the right size? You should choose clamps or chucks that fit your metal piece. The right size helps it stay secure. 5. What if I don’t have tools? You can use strong tape or rubber bands in a pinch. But it’s better to use proper tools for safety.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask me a question from the section you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Affordable Workholding Solutions For Securing Parts On A Budget-Friendly Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a few simple tools to hold parts on a budget-friendly metal lathe. A vise is a great choice because it can grip your work tightly. You can also use clamps to hold down your pieces. For small parts, make wooden or plastic jigs. These options are cheap and work well to keep your parts secure while you work.”}},{“@type”: “Question”,”name”: “How Can I Enhance The Stability Of My Workpieces When Using A Low-Cost Lathe Without Investing In Expensive Accessories?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your workpieces more stable on a low-cost lathe, you can try some simple tricks. First, use a heavier base for your lathe, like a thick piece of wood, to stop it from shaking. You can also clamp your workpiece tightly in the chuck, which is the part that holds it. Another idea is to balance your workpiece better by cutting a bit from all sides, so it doesn’t wobble. Lastly, keep your hands steady while working to help make clean cuts.”}},{“@type”: “Question”,”name”: “What Diy Workholding Methods Can I Create Using Common Materials For My Inexpensive Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make simple workholding tools for your metal lathe using stuff you already have. First, you can use a wooden block to hold small pieces while you work. Just drill a hole in the block for the piece to fit in. Second, rubber bands can help grip items tightly. Lastly, you can use strong clamps to hold larger pieces in place while you turn them.”}},{“@type”: “Question”,”name”: “Are There Specific Types Of Chucks Or Fixtures That Are Particularly Effective For Workholding On Cheap Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some types of chucks and fixtures work well on cheap metal lathes. A three-jaw chuck holds round pieces tightly. A four-jaw chuck is better for odd shapes. You can also use a faceplate for flat pieces. These tools help keep your work steady and safe while you cut.”}},{“@type”: “Question”,”name”: “How Do I Properly Align And Secure My Workpiece In A Low-Cost Lathe To Achieve Accurate Machining Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align your workpiece in a low-cost lathe, first make sure it is clean. Place the piece in the center of the lathe. Use the tailstock to hold it tightly without squeezing too hard. Next, check if it spins straight by turning it slowly. If it wobbles, adjust until it is straight.”}}]}