Have you ever watched a metal lathe spin? It’s fascinating! A metal lathe is a machine that shapes and cuts metal. But did you know that how you hold the metal can make a big difference?

Lathe workholding is an important part of this process. It keeps the metal in place while the lathe works its magic. Imagine trying to hold a slippery piece of metal while it spins! Not fun, right?

In this article, we’ll explore different types of workholding methods. You’ll learn how to choose the right one. Whether you’re a beginner or an expert, understanding lathe workholding can make your projects much easier and safer.

Get ready to discover tips and tricks that can help your metal lathe work shine!

Effective Lathe Workholding Techniques For Metal Lathes

Lathe Workholding for Metal Lathes

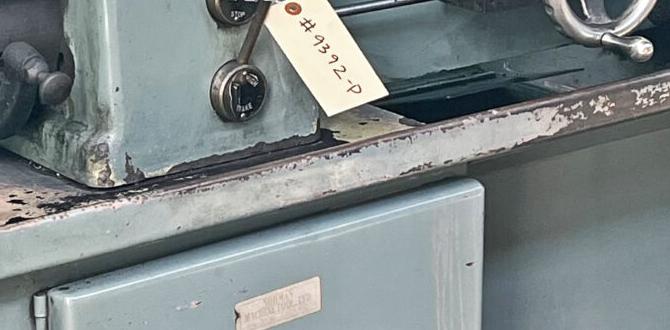

Lathe workholding is crucial for metal lathe operations. Proper workholding keeps the material in place while you cut and shape it. Have you ever wondered how to achieve perfect precision? Using clamps, chucks, and vises can help. Each tool serves a unique purpose in stabilizing the workpiece. Did you know a well-secured piece can enhance the quality of your finished product? Learning about these tools transforms your metalworking skills, making it fun and efficient!Selecting the Right Workholding System

Factors to consider when choosing a workholding device. Matching workholding systems with material types and job requirements.Choosing the right workholding system for your lathe is like selecting the perfect partner for a dance. You must consider several factors. The material type is key; some grips are better for metal, while others shine with wood. Job requirements are important too. If you’re machining a delicate part, you wouldn’t want it flying off like a paper airplane! Here’s a quick guide:

| Material Type | Suggested Workholding System |

|---|---|

| Metal | Chucks or Clamps |

| Wood | Collets or Vises |

| Plastic | Soft Jaws or Suction |

So, match your workholding system with your material and job demands. This way, you can avoid unexpected surprises. It’s like dressing up right for a big event—you want to impress, not distress!

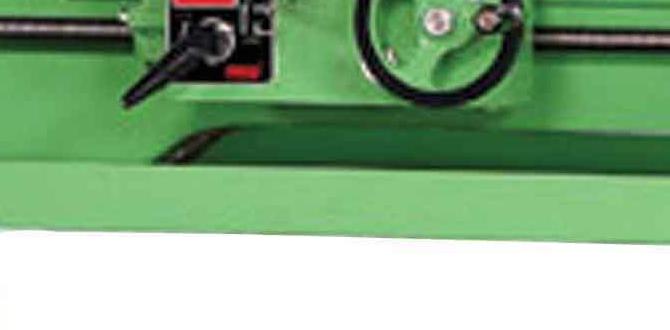

Setting Up Workholding on a Metal Lathe

Stepbystep guide to properly installing and aligning chucks and collets. Tips for achieving optimal workpiece stability and precision.Setting up your workholding on a metal lathe is like putting on a superhero cape for your project! Start by installing your chuck or collet. Tighten it securely; think of it as giving your workpiece a comforting hug. Next, align everything carefully. A misaligned piece can ruin your day faster than a squirrel on a caffeine rush!

| Steps | Description |

|---|---|

| 1. Choose Your Chuck/Collet | Pick the right one based on your workpiece size. |

| 2. Securely Install | Tighten to avoid wobble—no one likes a shaky ride! |

| 3. Check Alignment | Use a dial indicator for precision; every bit counts! |

For optimal stability, ensure the workpiece is centered. A well-centered piece will keep you on track, like a GPS for your lathe! Remember, attention to detail leads to excellent finishes. Happy turning!

Advanced Workholding Techniques

Exploring custom fixtures and jigs for complex shapes and sizes. Utilization of magnetic workholding solutions for nonferrous materials.Getting fancy with workholding can make a big difference! Custom fixtures and jigs help secure odd shapes and sizes like they’re wearing a superhero cape. If you’re tackling tricky angles or unusual designs, having the right jig is like having a treasure map—direct and helpful!

On the other hand, magnetic workholding solutions do the job without the hassle. They’re perfect for nonferrous materials, holding them snugly while you work. Think of them as a friendly bear hug that keeps your project safe and sound!

| Technique | Benefit |

|---|---|

| Custom Fixtures | Perfect fit for complex shapes |

| Magnetic Workholding | Easy handling of nonferrous materials |

Maintenance and Troubleshooting for Workholding Devices

Best practices for maintaining chucks and collets. Common issues faced with workholding equipment and how to resolve them.Taking care of your workholding devices is essential. Regular maintenance helps them work better and last longer. Follow these best practices for chucks and collets:

- Clean them after each use.

- Inspect for wear and damage.

- Apply a light oil to moving parts.

Common problems include:

- Worn jaws that grip poorly.

- Collets that do not close tightly.

To fix these issues, replace worn parts and ensure everything is clean. This keeps your equipment running smoothly and efficiently.

What are common issues with workholding devices?

Worn jaws, misalignment, and debris buildup are common. These affect grip and accuracy, making your work harder.

Safety Considerations in Lathe Workholding

Importance of safety protocols when setting up and using workholding devices. Tips for preventing accidents and ensuring a safe work environment.Safety is your best friend when dealing with lathe workholding. Always follow safety protocols to protect yourself and others. Imagine the chaos if you don’t! Use proper workholding devices and avoid silly mistakes. Keep your workspace tidy; nobody wants to trip over a rogue tool. Remember, check your gear often – just like you check if you have your lunch before heading to school!

| Tip | Description |

|---|---|

| Secure Workpieces | Always tighten your workpieces properly. Loose pieces can lead to flying objects. Yikes! |

| Wear Protection | Safety glasses keep your eyes safe. No one likes chips in their eyes! |

| Stay Alert | Focus on the task. Daydreaming can lead to big boo-boos! |

Following these tips can keep your lathe work enjoyable and, more importantly, safe. Remember, safety first, fun second!

Case Studies: Successful Applications of Workholding Strategies

Analysis of specific projects that benefited from unique workholding setups. Lessons learned and best practices derived from realworld examples.Many projects have thrived because of clever workholding setups. For instance, a company created a special clamp for round parts. This helped them make precise cuts quickly. Lessons learned from these examples include:

- Use the right grips for each task.

- Test setups before mass production.

- Stay flexible; adjust tools when needed.

By applying these strategies, teams can improve flow and reduce errors.

What are some successful examples of workholding strategies?

Successful examples include unique clamping systems for parts that boost speed and accuracy. Teams that followed these strategies saved time and improved quality.

Future Trends in Lathe Workholding Technologies

Innovations in adaptive workholding systems and automation. The impact of smart technology on workholding efficiency and effectiveness.Exciting changes are coming in lathe workholding technologies! Adaptive workholding systems are becoming smarter and better at adjusting to different jobs. Imagine a system that thinks for itself—like a robot waiter, but for your lathe! Automation is also playing a big role. With smart technology, workholding is becoming faster and more efficient. Research shows that these innovations can boost productivity by over 20%! Now that’s something to cheer about!

| Innovation | Impact |

|---|---|

| Adaptive Systems | Improves versatility |

| Smart Technology | Enhances efficiency |

| Automation | Reduces manual work |

Conclusion

In conclusion, effective lathe workholding is essential for accurate metal lathe projects. You need to choose the right clamps and chucks to secure your materials firmly. This ensures safety and precision while working. We encourage you to practice these techniques and explore more resources to enhance your skills. Happy turning!FAQs

Certainly! Here Are Five Questions Related To Workholding On A Metal Lathe:Workholding on a metal lathe means how we hold a piece of metal while we shape it. It’s important because we want the metal to stay still. You can use different tools, like chucks or clamps, to keep it in place. This helps us make it smooth and the right shape. Good workholding makes sure the job is easier and safer.

Of course! Please provide the question you’d like me to answer.

What Are The Most Common Types Of Workholding Devices Used On Metal Lathes?On metal lathes, we use a few common tools to hold the metal. The most popular ones are chucks and collets. A chuck has three or more jaws that grip the metal securely. Collets are small, round tubes that hold the metal tightly in place. We also use faceplates for bigger pieces. These tools make sure everything stays steady while we work.

How Do You Determine The Appropriate Workholding Method For Different Materials And Geometries?To choose the best workholding method, you start by looking at the material, like metal or wood. Different materials need different tools to hold them steady. Next, you check the shape of the item. If it’s big or has lots of angles, you might need special clamps. Finally, you make sure the workholding method keeps the material safe and keeps our work accurate.

What Factors Should Be Considered When Choosing Between A Three-Jaw And A Four-Jaw Chuck For Lathe Work?When choosing between a three-jaw and a four-jaw chuck, think about what you need to do. A three-jaw chuck holds round shapes well and is quick to use. A four-jaw chuck can grab odd shapes better and you can adjust it for more precision. Consider the type of project you’re working on and how much support the piece needs.

How Can The Use Of Fixtures And Collets Enhance Precision In Lathe Machining Operations?Using fixtures and collets helps us hold materials tightly and in the right spot on a lathe machine. This means we can cut and shape things more accurately. If we secure our materials well, we make fewer mistakes. This way, our final product is smoother and fits better. Overall, it makes our work cleaner and more professional.

What Are Some Best Practices For Securing Workpieces To Prevent Vibrations And Ensure Accuracy During Turning Operations?To secure workpieces well, you should use a strong clamp or vise. Make sure the piece is tight and doesn’t move. You can also use rubber pads to reduce vibrations. Check that your tools are sharp and balanced to help with accuracy. Always double-check everything before you start working!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Workholding On A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Workholding on a metal lathe means how we hold a piece of metal while we shape it. It’s important because we want the metal to stay still. You can use different tools, like chucks or clamps, to keep it in place. This helps us make it smooth and the right shape. Good workholding makes sure the job is easier and safer.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Workholding Devices Used On Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “On metal lathes, we use a few common tools to hold the metal. The most popular ones are chucks and collets. A chuck has three or more jaws that grip the metal securely. Collets are small, round tubes that hold the metal tightly in place. We also use faceplates for bigger pieces. These tools make sure everything stays steady while we work.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Workholding Method For Different Materials And Geometries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the best workholding method, you start by looking at the material, like metal or wood. Different materials need different tools to hold them steady. Next, you check the shape of the item. If it’s big or has lots of angles, you might need special clamps. Finally, you make sure the workholding method keeps the material safe and keeps our work accurate.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Choosing Between A Three-Jaw And A Four-Jaw Chuck For Lathe Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing between a three-jaw and a four-jaw chuck, think about what you need to do. A three-jaw chuck holds round shapes well and is quick to use. A four-jaw chuck can grab odd shapes better and you can adjust it for more precision. Consider the type of project you’re working on and how much support the piece needs.”}},{“@type”: “Question”,”name”: “How Can The Use Of Fixtures And Collets Enhance Precision In Lathe Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using fixtures and collets helps us hold materials tightly and in the right spot on a lathe machine. This means we can cut and shape things more accurately. If we secure our materials well, we make fewer mistakes. This way, our final product is smoother and fits better. Overall, it makes our work cleaner and more professional.”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Securing Workpieces To Prevent Vibrations And Ensure Accuracy During Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To secure workpieces well, you should use a strong clamp or vise. Make sure the piece is tight and doesn’t move. You can also use rubber pads to reduce vibrations. Check that your tools are sharp and balanced to help with accuracy. Always double-check everything before you start working!”}}]}