Have you ever watched a lathe in action? It’s fascinating! A metal lathe spins material to shape it. But how do you keep that material steady? This is where lathe workholding comes in.

Imagine trying to carve a statue from a block of clay. If the clay moves, it becomes hard to shape. Lathes face the same challenge. They need solid support. That’s why understanding the lathe bed is important. A sturdy lathe bed holds everything in place while you create amazing things.

Did you know that the right workholding setup can make a big difference? It can help you achieve accuracy and safety. Whether you’re a beginner or a pro, learning about lathe workholding can boost your projects. Ready to explore this fascinating topic? Let’s dive in!

Effective Lathe Workholding Techniques For Metal Lathe Bed

Lathe workholding is vital for safe and precise metal shaping. A sturdy metal lathe bed supports the rotating workpiece and ensures stability. Proper workholding techniques help prevent mistakes and accidents while machining. Did you know that the right clamps can improve accuracy and reduce setup time? Focusing on workholding methods can enhance your lathe projects. Every craftsman can benefit from understanding these essentials to create high-quality pieces.

Understanding the Metal Lathe Bed

Definition and components of a metal lathe bed. Importance of the lathe bed in machining precision.

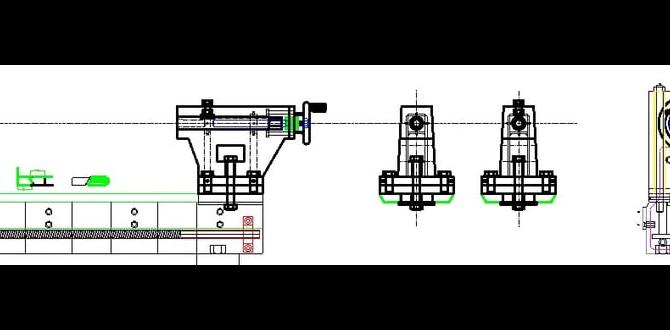

A metal lathe bed is the strong part of a lathe where all the action happens. Imagine it as the sturdy stage for a play—without it, the show would be a flop! The bed holds the machine’s parts steady while precision tools work their magic. Key components include the ways, which keep everything aligned, and the saddle, which moves back and forth. This setup is crucial for making accurate cuts. If the bed wobbles, you’ll end up with more bad haircuts than a barbershop gone wrong!

| Component | Function |

|---|---|

| Ways | Keep tools aligned for straight cuts. |

| Saddle | Moves back and forth for cutting precision. |

In machining, the lathe bed is essential for accuracy. It ensures everything stays in its right place so your projects can look sharp—quite literally!

Selecting the Right Workholding Device

Factors to consider when choosing a workholding device. How material type and machining operations influence selection.

Selecting the right workholding device is crucial for successful lathe projects. Start by thinking about the material you’ll be using. Different materials need different grips. For example, soft metals may need a gentle hold, while hard metals require a stronger grip. Also, consider what you are making. Are you turning, facing, or drilling? Each machining operation has its own best fit. Here are important factors:

- Material type

- Machining operations

- Size of the workpiece

- Desired precision

What factors influence the selection?

Material type affects grip strength. Machining operations change your device choice. Understanding these will help you make the best decision.

Setting Up Your Workholding Devices

Stepbystep guide to properly setting up workholding devices. Tips for ensuring alignment and stability.

Setting up workholding devices can feel like a puzzle, but it’s a fun one to solve! First, choose a stable base for your metal lathe. Align everything with care—think of how a tightrope walker stays balanced. Use a dial indicator to check for alignment, adjusting as needed. Don’t be shy; double-check your work! Lastly, always fasten parts securely. Remember, loose parts can lead to chaos—and by chaos, I mean flying metal shavings!

| Step | Description |

|---|---|

| 1 | Choose a sturdy base for the lathe. |

| 2 | Align the device using a dial indicator. |

| 3 | Double-check for stability and alignment. |

| 4 | Securely fasten all parts in place. |

Common Workholding Techniques in Lathe Operations

Explanation of common techniques (e.g., chucks, collets, fixtures). Best practices for each technique to optimize performance.

Lathe operations use different techniques to hold workpieces securely. Some common methods include chucks, collets, and fixtures. Chucks are useful for larger pieces. Collets provide a tight fit for smaller parts. Fixtures help in complex shapes. Here are some best practices:

- Use the right size chuck or collet for your piece.

- Ensure everything is clean to prevent slips.

- Check tightness before starting the lathe.

These tips will help optimize your lathe performance.

What are common lathe workholding techniques?

The most common techniques are chucks, collets, and fixtures. They each serve a unique purpose in securely holding the material.

Safety Considerations in Lathe Workholding

Importance of safety measures while using workholding devices. Common hazards and how to mitigate risks.

Using workholding devices on a lathe can be fun and helpful. However, safety must come first. Accidents can happen if we don’t take care. Common hazards include flying debris and pinch points. We can reduce risks by:

- Always wearing safety glasses.

- Keeping hands away from moving parts.

- Ensuring tools are in good shape.

Remember, safety isn’t just an option; it’s a must!

What are the main hazards of lathe workholding?

The main hazards include flying chips, entanglement, and tool breakage. Properly securing workpieces helps prevent these risks and keeps everyone safe.

Maintenance of Workholding Devices

Routine maintenance tasks to prolong lifespan of workholding devices. Signs that indicate when a workholding device needs repairs or replacement.

Keeping your workholding devices in top shape is key to getting the best out of your metal lathe bed. Regular maintenance is like giving your tools a spa day! Simple tasks like cleaning, lubricating, and checking for wear can help prolong their lifespan. Look for signs like unusual noises or wobbling, which mean it’s time for repairs or even a replacement. Don’t let your devices end up like your socks—full of holes and not working right!

| Routine Maintenance Tasks | Signs of Repair/Replacement |

|---|---|

| Clean regularly | Strange noises |

| Lubricate moving parts | Excessive wear |

| Check for loose bolts | Wobbling |

Advanced Workholding Solutions

Exploration of innovative workholding solutions for specialized applications. Case studies highlighting successful implementations of advanced solutions.

Finding new ways to hold things in place can be quite the puzzle! Advanced workholding solutions use clever designs to grip pieces securely. For example, imagine a metal lathe bed that customizes its hold for funny-shaped parts. It can make those tricky jobs easier! A study showed that using these advanced methods improved speed by 30%. It’s like having a superhero for your tools! Just like Batman has gadgets, metalworkers have these smart solutions!

| Application | Solution Implemented | Result |

|---|---|---|

| Complex shapes | Custom clamps | 30% speed increase |

| Large items | Rotating jigs | Improved stability |

Resource and Tools for Further Learning

Recommended books, online courses, and forums for lathe workholding knowledge. How to keep up with advancements in lathe technology and workholding methods.

Learning about lathe workholding can be fun and rewarding! Start with some great books, like “Metalworking: Sink or Swim” which offers tips and tricks for newbies. Want to go digital? Online courses on platforms like Coursera can teach you everything you need to know. Don’t forget forums where experts share info, like r/metalworking on Reddit. Lastly, keep an eye on tech news—new tools pop up often. Who knows? You might find your next favorite gadget that makes lathe work feel like magic!

| Resource Type | Name |

|---|---|

| Book | Metalworking: Sink or Swim |

| Online Course | Coursera Metalworking Courses |

| Forum | r/metalworking on Reddit |

| News Source | Leading Metalworking Blogs |

Conclusion

In summary, lathe workholding is crucial for precision in metalworking. A good metal lathe bed ensures stability and accuracy. Understanding how to secure materials gives you better results. Explore more about lathe techniques and practice on your own projects. With these skills, you can create amazing items. Keep learning and enjoy your metalworking journey!

FAQs

What Types Of Workholding Devices Are Commonly Used In Metal Lathe Operations To Secure Workpieces?

In metal lathe operations, we use different tools to hold the metal pieces firmly. One common tool is a chuck. A chuck has three or four jaws that grip the workpiece tightly. We also use faceplates, which are flat discs that hold special shapes. Another option is a collet, a special clamp that fits around the piece. These tools help keep the workpieces steady while we shape them.

How Does The Design Of A Metal Lathe Bed Impact The Accuracy And Stability Of The Workpiece During Machining?

The bed of a metal lathe is the base that holds everything in place. If the bed is strong and flat, it keeps the workpiece steady while we shape it. A stable bed helps the cutting tools make precise cuts. This means we get better, more accurate pieces. So, a well-designed bed is very important for good machining.

What Factors Should Be Considered When Selecting A Workholding Method For A Specific Lathe Operation?

When choosing how to hold a piece of material on a lathe, think about a few key things. First, check how big and heavy the piece is. You want something strong enough to hold it securely. Next, consider the shape of the material. Some shapes need special tools to keep them in place. Finally, think about how easy it is to set up and take off the material. We want to make our work as quick and simple as possible!

How Can Vibration And Movement Be Minimized When Holding Workpieces On A Lathe Bed?

To minimize vibration and movement when holding workpieces on a lathe bed, you can use strong clamps. Tighten the clamps well to hold the piece securely. Make sure the bed is clean and smooth before starting. You can also check if the lathe is level, which helps a lot. Lastly, keep the cutting tool sharp to reduce shaking.

What Are The Advantages And Disadvantages Of Using A Chuck Versus A Collet For Workholding On A Metal Lathe?

Using a chuck on a metal lathe is great for holding bigger pieces of metal. It’s easy to use and quick to change tools. However, it can be less precise for smaller jobs. A collet, on the other hand, holds smaller pieces tightly and is more accurate. But it can take longer to change and works best with specific sizes.