Have you ever watched a metal lathe in action? It’s fascinating to see how it shapes metal into incredible designs. A key player in this process is the lathe workholding system, especially the metal lathe chuck.

Imagine trying to carve a statue from a block of stone without a solid way to hold the stone in place. That’s a bit like working on a lathe without a good chuck. It grips the metal securely while the machine spins. This makes sure the workpiece doesn’t move or slip.

Did you know there are different types of lathe chucks? Each has its own special purpose. Some chucks can hold round pieces, while others can grip odd shapes. Understanding these differences can make your lathe projects easier and more enjoyable.

In this article, we will explore how lathe workholding affects your metalworking success. You’ll learn tips to choose the right chuck and improve your craft. Ready to dive deeper into the world of metal lathe chucks? Let’s get started!

Essential Guide To Lathe Workholding: Metal Lathe Chuck Explained

Understanding Lathe Workholding with Metal Lathe Chucks

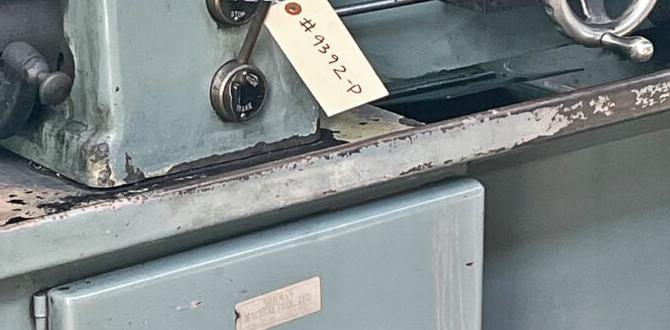

Metal lathe chucks are vital for secure workholding in lathe operations. These handy tools clamp material in place, ensuring accuracy and safety during machining. Did you know that different types of chucks, like three-jaw and four-jaw models, cater to various tasks? Choosing the right chuck can significantly impact your project’s success. Whether you’re a beginner or an experienced machinist, mastering lathe workholding techniques can elevate your skills and projects.Selecting the Right Chuck for Your Project

Factors to consider: material, size, and type of workpiece. Comparison between features of different chuck types.Choosing the right chuck is essential for successful lathe work. Consider these key factors:

- Material: Different materials, like steel or aluminum, affect strength.

- Size: Make sure the chuck size matches your workpiece.

- Type: There are various types of chucks, such as three-jaw or four-jaw, each with unique features.

Each type offers something special for different projects. A three-jaw chuck is great for quick setups, while a four-jaw chuck gives better grip for odd shapes. Understanding these differences can help you pick the best chuck for your needs.

What should I consider when selecting a chuck?

Consider material, size, and type of workpiece. Each factor impacts how well the chuck will perform on your project.

Set Up and Installation of Lathe Chucks

Stepbystep guide to installing a threejaw chuck. Tips on aligning and securing chucks effectively.Installing a three-jaw chuck is straightforward. Follow these steps:

- First, clean the lathe’s spindle. Dirt can cause problems.

- Next, carefully lift the chuck and position it on the spindle.

- Tighten the screws in a star pattern. This ensures even pressure.

- Check alignment by spinning the chuck. It should be smooth and balanced.

Secure your chuck well. Check it before each use. This makes your work safer and more precise.

How do you align a lathe chuck?

To align a lathe chuck, use a dial indicator. Keep it steady and mark any shifts. Adjust the chuck until it spins true. Regular checks maintain accuracy.

Tips for securing chucks:

- Always use the right tools.

- Double-check the tightening process.

- Inspect the chuck for wear or damage.

Maintaining Your Metal Lathe Chuck

Regular maintenance practices to extend chuck lifespan. Common issues and troubleshooting tips for lathe chucks.Taking care of your metal lathe chuck is like giving it a hug every day. Regular cleaning and lubrication can help it last longer. Dust and grime are its worst enemies. Check for any damage often; think of it as a check-up for your chuck! Common issues include misalignment and wear. If you notice it not gripping well, it’s time to adjust it. Here’s a quick checklist to keep your chuck happy:

| Maintenance Task | Frequency |

|---|---|

| Clean chuck jaws | After every use |

| Lubricate moving parts | Weekly |

| Inspect for damage | Monthly |

| Check chuck alignment | Before major projects |

With these simple steps, your chuck will be the star of your workshop. Remember, a happy chuck means happy turning!

Advanced Techniques for Improved Workholding

Utilizing soft jaws for customized gripping. Techniques for balancing workpieces on the lathe.Soft jaws are great for custom gripping of unique shapes. They can hug your workpiece snugly, which improves stability. This means less vibration and a better finish. To balance workpieces, make sure weight is even. You can do this by:

- Measuring the piece carefully.

- Using a test indicator for precision.

- Adjusting the positioning until it spins smoothly.

These simple techniques can boost your lathe performance. They help ensure your projects turn out just right!

What are soft jaws in lathe workholding?

Soft jaws are specially designed grips on the lathe chuck. They adapt to fit different shapes, helping to hold your work securely.

Safety Practices When Using Metal Lathe Chucks

Essential safety gear and equipment. Best practices to avoid accidents during lathe operation.Using metal lathe chucks can be fun, but safety is important. Always wear the right gear to stay safe. This includes gloves, goggles, and ear protection. You need to follow best practices to avoid accidents. Make sure to secure the workpiece tightly, and check for loose parts before starting. Here are some quick tips:

- Keep the work area clean.

- Don’t wear loose clothing.

- Always check the machine parts.

Following these safety rules helps everyone stay safe while working.

What is the best safety gear for lathe work?

The best safety gear when using a lathe includes safety glasses, gloves, and ear protection. Wearing this gear can protect you from flying debris and loud noises. Always stay alert while working!

Future Trends in Lathe Workholding Technology

Innovations in metal lathe chuck designs. The impact of automation and CNC technology on workholding solutions.New designs in metal lathe chucks are changing how we do work. Innovations aim for faster setups and better grip. This helps make precise parts quickly and easily. Automation and CNC technology are also making a big difference. Machines can adjust without human help. They offer consistency and accuracy each time. Together, these trends lead to smarter, faster manufacturing.

What are the latest trends in lathe workholding technology?

The latest trends include more efficient chuck designs and advanced automation. These innovations help reduce time and improve precision.

Key Points:

- Better grip on materials

- Faster setup times

- Automation improves consistency

Conclusion

In summary, lathe workholding using a metal lathe chuck is essential for accurate machining. You secure materials firmly for precise cuts. Understanding different chuck types helps you choose the right one for your projects. Explore more about lathe workholding techniques to improve your skills. Practice using a chuck and watch your creations come to life!FAQs

Sure! Here Are Five Related Questions About Lathe Workholding And Metal Lathe Chucks:A metal lathe is a machine that shapes metal. We hold the metal piece with something called a chuck. A chuck grips the metal tightly so it doesn’t move. This helps us cut or shape the metal smoothly. Having a good chuck means our work will look better!

Sure! Please go ahead and ask your question, and I’ll answer it for you.

What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Differ In Functionality?Metal lathes use different types of chucks to hold metal pieces. The most common are three-jaw chucks, which grip items tightly and easily. There are also four-jaw chucks, which let you grab things in different spots. Lastly, there are special chucks for certain jobs, like collet chucks. Each type helps us work on the metal in different ways.

How Do You Properly Set Up And Align A Chuck On A Metal Lathe For Optimal Workholding?To set up a chuck on a metal lathe, first, clean the chuck and the lathe’s spindle. Next, place the chuck on the spindle and tighten it until it is secure. Check the alignment by using a dial indicator, which helps us see if it spins straight. If it’s not straight, you can adjust it until it is. Finally, double-check that everything is tight before starting your work.

What Are The Advantages Of Using A 3-Jaw Chuck Versus A 4-Jaw Chuck In Lathe Applications?Using a 3-jaw chuck is faster than a 4-jaw chuck. It holds round pieces tightly and keeps them centered. You can quickly change what you’re working on. A 4-jaw chuck is good for odd shapes, but it takes more time. So, for speed and easy use, the 3-jaw chuck is often better.

How Do You Ensure That A Workpiece Is Securely Held In A Chuck To Prevent Movement During Machining?To keep a workpiece secure in a chuck, you should first clean the chuck and workpiece. Then, you can place the workpiece inside the chuck. Next, close the chuck tightly by turning the handle or using a lever. Finally, check that the workpiece doesn’t move by gently pushing it. This way, it stays safe while you work on it.

What Maintenance Practices Should Be Followed To Keep Lathe Chucks In Optimal Working Condition?To keep lathe chucks in good shape, you should clean them regularly. Remove dust and chips after each use. Check for any damage or wear, like cracks or dents. You can oil the moving parts to ensure they work smoothly. Finally, store them in a safe place to avoid damage.