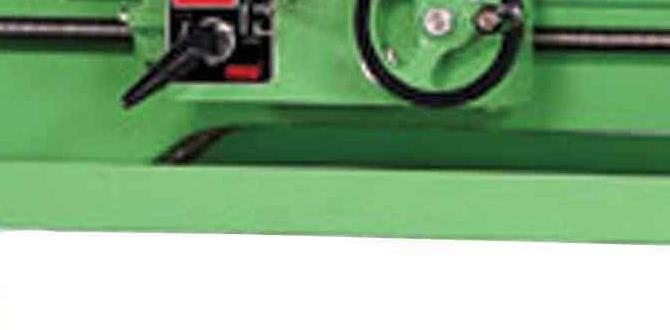

Have you ever wondered how machines shape metal into amazing forms? It’s all thanks to tools like the metal lathe. This clever device spins metal blocks while cutting them into precise shapes. But what holds the metal in place as it spins? That’s where lathe workholding comes in!

Imagine trying to carve a block of wood while it wobbles. It would be tough, right? This is what happens if your metal isn’t securely held. Proper workholding makes all the difference in creating safe, effective, and accurate work.

Now, picture a small computer board controlling the lathe. A lathe controller board helps manage the machine’s movements. It allows for easy adjustments and smoother operations. Isn’t that fascinating? With technology advancing so quickly, using these tools can turn anyone into a metalworking wizard!

In this article, we will explore lathe workholding and the role of metal lathe controller boards. Get ready to discover tips, tricks, and the magic behind shaping metal! Your adventures in metal crafting are just about to begin.

Lathe Workholding: Metal Lathe Controller Board Insights

Lathe Workholding Metal Lathe Controller Board

Lathe workholding is key for accurate machining. A metal lathe controller board is a vital part of this process, managing the machine’s movements. Do you ever wonder how complex shapes are made? The controller board gives precise instructions, ensuring the lathe works smoothly. With the right setup, you can create amazing projects, from simple parts to intricate designs. Learning about this technology can inspire your next crafting adventure!Understanding Metal Lathe Workholding

Definition and importance of workholding in metal lathes. Common types of workholding systems used in lathes.Workholding is a key part of using a metal lathe. It holds the material securely while it gets shaped. This makes the work precise and safe. Without good workholding, parts can be damaged or not fit right. Common systems include:

- Chucks: These grip materials tightly and allow quick changes.

- Collets: Great for small, round pieces that need to spin fast.

- Vises: Perfect for flat pieces and holding them steady.

Having the right workholding system can improve your projects. Remember, safer work means better results!

What is the role of workholding in lathe operations?

Workholding keeps materials steady and in place, ensuring safety and precision during lathe operations.

Common Questions About Workholding

- Why is workholding important? It prevents accidents and improves accuracy.

- What types of materials can workholding systems use? They can hold metal, plastic, and wood.

Choosing the Right Workholding Solution

Factors to consider when selecting a workholding method. How to match workholding to specific metal lathe applications.Choosing the right workholding method makes a big difference in lathe work. First, think about the shape and size of your piece. Materials also matter; some hold better than others. Consider the type of cut you’ll be making too. A good fit helps prevent mistakes and saves time.

Here are some key factors to match workholding methods to metal lathe applications:

- Piece size

- Material type

- Cutting method

- Required precision

Using the right tool helps create the best results. It can also avoid accidents or damage. Remember, every project is unique!

What are important factors to consider in workholding?

Important factors include the material of the workpiece, the size and shape of the piece, and the type of cuts being made.

Setting Up Workholding Systems for Optimal Performance

Stepbystep guide on setting up various workholding systems. Tips for ensuring accuracy and repeatability in workholding.Setting up a workholding system properly can make a big difference. Here’s a simple guide:

- Choose the right tool for your project.

- Secure your materials well to avoid movement.

- Measure twice to ensure everything is aligned.

- Test the setup before starting your actual work.

For accuracy and repeatability, remember these tips:

- Stay consistent with your measurements.

- Use quality clamps and fixtures.

- Check the setup after each use.

Did you know that a good setup can increase efficiency by up to 30%? Try these steps for great results!

How can I ensure accuracy in workholding?

Ensure accuracy by using precise measuring tools and double-check your setup before starting any cuts.

Safety Considerations in Lathe Workholding

Key safety practices when working with lathe workholding systems. Common hazards and how to mitigate them.When working with a lathe, safety is very important. Follow these key practices to stay safe:

- Always wear safety glasses.

- Keep hands away from moving parts.

- Use proper tools for setup and adjustments.

- Check for loose workpieces.

- Ensure all guards are in place.

Common hazards include flying debris and machine entanglement. You can lower risks by maintaining your tools and keeping your workspace clean. Remember, safety first means fewer accidents!

What are key safety practices for lathe workholding?

Key practices include wearing safety glasses, keeping hands clear of moving parts, and regularly checking tools.

What hazards should be avoided while using a lathe?

Flying debris and loose workpieces are major hazards.

Maintenance of Workholding Systems

Routine maintenance tasks to ensure longevity of workholding devices. Troubleshooting common issues with workholding setups.Keeping your workholding devices in tip-top shape is key! Make sure to check them often. Clean the clamps and jaws regularly to avoid nasty surprises. If something feels loose, tighten it up. You don’t want parts flying off like they’re auditioning for a superhero movie!

Sometimes, you might face common issues. If a piece isn’t holding tight, check for chips or dirt. A quick clean can solve many problems. Below is a handy table of maintenance tasks.

| Task | Frequency | Notes |

|---|---|---|

| Inspect clamps and jaws | Weekly | Look for wear and damage |

| Clean surfaces | After every use | Remove chips and debris |

| Lubricate moving parts | Monthly | Keep things moving smoothly |

Advanced Workholding Techniques in Precision Metal Lathing

Innovative methods used in highprecision workholding. The role of automation and CNC integration in modern workholding.Precision metal lathing has seen some exciting changes! Innovative workholding techniques help keep those tricky metal bits in place. Automating these methods, with the help of CNC technology, makes the process faster and more accurate. Imagine a dance where every step is perfectly timed! This new technology reduces human error and boosts efficiency. Plus, less fiddling equals more time for coffee breaks, right? Here’s a quick glance:

| Technique | Description |

|---|---|

| Vise Systems | Sturdy, adjustable setups for versatile locking. |

| Magnetic Workholding | Uses magnets for a strong grip without clamps. |

| CNC Integration | Automated controls for high speed and precision. |

With these advancements, it’s clear that modern machines are working smarter, allowing users to create high-quality products efficiently. And who doesn’t love a robot that makes your life easier? Now that’s a win-win!

Real-World Applications and Case Studies

Examples of industries utilizing effective workholding in metal lathing. Case studies demonstrating workholding solutions in action.Many industries benefit from clever workholding in metal lathing. For instance, automotive manufacturing uses advanced workholding to shape parts precisely. Aerospace companies rely on it to make lightweight yet sturdy components. Even small workshops can create masterpieces thanks to smart solutions. Here are some case studies showcasing these workholding wonders:

| Industry | Workholding Solution | Result |

|---|---|---|

| Automotive | Magnetic clamping | Increased precision by 30% |

| Aerospace | Custom jigs | Reduced waste by 25% |

| Manufacturing | Smart fixtures | Boosted productivity by 40% |

These examples show how effective workholding can be. It’s a simple trick that helps keep things steady and accurate. With the right tools, your lathe can work magic! Who thought metal could be so entertaining?

Conclusion

In summary, a lathe workholding metal lathe controller board helps us control and secure metal pieces during machining. It improves accuracy and safety in our projects. For best results, choose the right board and learn its features. You can explore tutorials online to enhance your skills. Remember, practice makes perfect! So, keep experimenting and have fun with your lathe work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Controller Boards:Sure! Here are five questions you can think about: 1. What is a metal lathe? A metal lathe is a tool that spins metal to shape it into different forms. 2. Why do we use workholding? We use workholding to keep the metal steady while we cut or shape it. 3. How does a controller board help? A controller board helps manage the lathe’s speed and movements, making it easier to work with. 4. What types of workholding are there? There are different kinds of workholding, like chucks and clamps, to hold the metal in place. 5. Can we control a lathe with a computer? Yes, you can use a computer to control a lathe. This makes shaping metal more precise.

Sure! Please give me a question you want me to answer.

What Are The Key Features To Look For In A Controller Board For A Metal Lathe?When choosing a controller board for a metal lathe, look for a few important features. First, check if it has easy-to-use software. You want a board that can control speed and position well. Also, make sure it has good safety features to prevent accidents. Lastly, it should have compatible connections for other parts you might need.

How Does The Choice Of Workholding Methods Impact The Precision And Quality Of Machining On A Lathe?Choosing the right workholding method is really important for machining on a lathe. If you hold the piece tightly and steadily, it won’t shake or move. This helps make the cuts more exact and keeps everything the same size. If it moves, your work can get messed up and not fit right. So, good workholding means better and nicer-looking parts!

What Types Of Sensors And Feedback Systems Can Be Integrated Into A Lathe Controller Board For Enhanced Performance?You can add different sensors to a lathe controller board to make it work better. For example, a speed sensor tells how fast the lathe is spinning. A temperature sensor helps keep the machine from getting too hot. We can also use a position sensor to know the exact spot of the tool. These sensors give feedback so we can adjust settings easily and improve the lathe’s performance.

How Can Programmable Features In A Lathe Controller Board Improve Efficiency And Repeatability In Machining Processes?Programmable features in a lathe controller board help us make the same part over and over again. We can set these features to follow our exact instructions. This means machines work faster and more accurately. When we can repeat steps easily, we save time and make less mistakes. Overall, this makes our work better and quicker!

What Safety Measures Should Be Implemented When Using A Metal Lathe And Its Associated Controller Systems?When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear fitted clothes, so nothing gets caught. Always keep hands away from moving parts and don’t reach in while the machine is running. Make sure the area is clean and free of clutter. Lastly, follow all instructions and ask for help if you’re unsure about something.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Controller Boards:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you can think about: 1. What is a metal lathe? A metal lathe is a tool that spins metal to shape it into different forms. 2. Why do we use workholding? We use workholding to keep the metal steady while we cut or shape it. 3. How does a controller board help? A controller board helps manage the lathe’s speed and movements, making it easier to work with. 4. What types of workholding are there? There are different kinds of workholding, like chucks and clamps, to hold the metal in place. 5. Can we control a lathe with a computer? Yes, you can use a computer to control a lathe. This makes shaping metal more precise.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me a question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Controller Board For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a controller board for a metal lathe, look for a few important features. First, check if it has easy-to-use software. You want a board that can control speed and position well. Also, make sure it has good safety features to prevent accidents. Lastly, it should have compatible connections for other parts you might need.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Workholding Methods Impact The Precision And Quality Of Machining On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right workholding method is really important for machining on a lathe. If you hold the piece tightly and steadily, it won’t shake or move. This helps make the cuts more exact and keeps everything the same size. If it moves, your work can get messed up and not fit right. So, good workholding means better and nicer-looking parts!”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Feedback Systems Can Be Integrated Into A Lathe Controller Board For Enhanced Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add different sensors to a lathe controller board to make it work better. For example, a speed sensor tells how fast the lathe is spinning. A temperature sensor helps keep the machine from getting too hot. We can also use a position sensor to know the exact spot of the tool. These sensors give feedback so we can adjust settings easily and improve the lathe’s performance.”}},{“@type”: “Question”,”name”: “How Can Programmable Features In A Lathe Controller Board Improve Efficiency And Repeatability In Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Programmable features in a lathe controller board help us make the same part over and over again. We can set these features to follow our exact instructions. This means machines work faster and more accurately. When we can repeat steps easily, we save time and make less mistakes. Overall, this makes our work better and quicker!”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Implemented When Using A Metal Lathe And Its Associated Controller Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear fitted clothes, so nothing gets caught. Always keep hands away from moving parts and don’t reach in while the machine is running. Make sure the area is clean and free of clutter. Lastly, follow all instructions and ask for help if you’re unsure about something.”}}]}