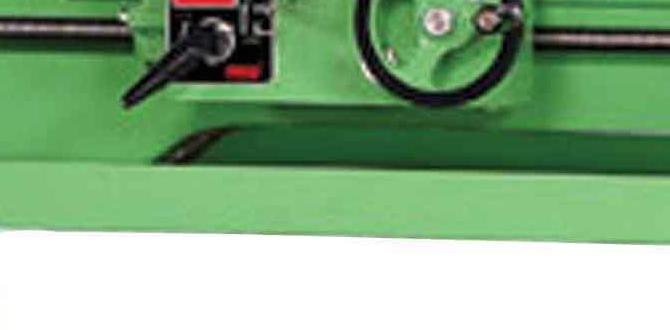

Have you ever wondered how metal is shaped and formed into useful items? The magic often happens on a machine called a lathe. In the world of metalworking, lathe workholding is a crucial part of the process. This technique allows the metal to stay secure while it is being shaped.

Imagine designing a beautiful metal vase. You have your idea, but if the metal moves while you work, your dream can quickly become a disaster. Proper workholding makes sure the metal stays in place, helping you create perfect designs.

But what about keeping your lathe in tip-top shape? Regular lathe maintenance is key to making sure your machine runs smoothly. Just like you care for a car, your lathe needs attention too. Without proper care, it may not work as well as it should.

In this article, we will explore the importance of lathe workholding and essential metal lathe maintenance tips. You will learn how to take care of your lathe and improve your skills. Get ready to dive into the fascinating world of metalworking!

Essential Guide To Lathe Workholding And Metal Lathe Maintenance

Lathe Workholding and Metal Lathe Maintenance

Lathe workholding is essential for precision in metalworking. Proper setup ensures your materials stay secure and positioned right during cutting. Did you know that nearly 50% of errors come from poor workholding? Regular maintenance of your metal lathe is key. Lubrication and cleaning help it run smoothly. This not only extends the machine’s life but also improves accuracy. Remember, a well-maintained lathe makes every project easier and more enjoyable!Types of Workholding Devices

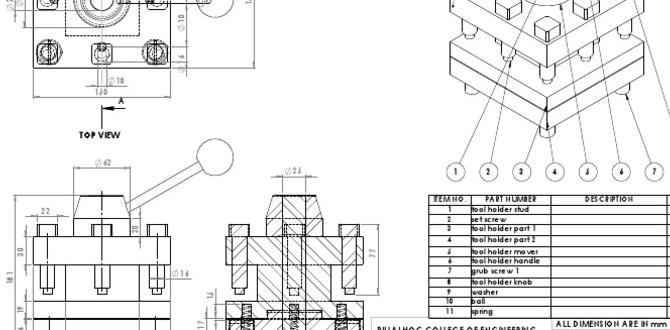

Description of chucks, collets, and faceplates. Pros and cons of each type of workholding device.Workholding devices help keep your materials steady while you work. Three common types are chucks, collets, and faceplates. Each has its own strengths and weaknesses.

- Chucks: Great for holding larger pieces. They are versatile but can be hard to use for smaller items.

- Collets: Ideal for small, precise work. They hold items firmly but may not fit larger pieces.

- Faceplates: Best for flat or odd-shaped items. They provide good support, but setup can take time.

Choosing the right device can make your project easier and faster!

What are the types of workholding devices?

The main types of workholding devices are chucks, collets, and faceplates. Each type has a different purpose and can be used together for best results. Chucks hold larger materials, collets focus on small parts, and faceplates support flat items.

Choosing the Right Workholding Solution for Your Project

Factors to consider: material, size, and complexity. Tips for assessing workpiece stability and alignment.Choosing the right workholding solution can make or break your project. Think about the material of your workpiece. Is it soft like aluminum or hard like steel? Next, consider the size. Bigger pieces need sturdier holds. Lastly, check the complexity of your design. Complex shapes may need special tools to keep them steady. Assess stability by ensuring your piece aligns well. A stable and aligned workpiece helps you create better results!

What should I consider for workholding?

Focus on the material, size, and shape of your workpiece to find the best solution. Balance is key to keeping everything secure while you work.

Quick Tips:

- Check if the material is soft or hard.

- Choose the right size for solid support.

- Look at the design—simple or complex?

Best Practices for Metal Lathe Maintenance

Routine maintenance tasks for optimal lathe performance. Importance of cleaning and lubricating moving parts.Keeping your metal lathe in tip-top shape is easier than you think! Simple, routine tasks can make a big difference. First, always clean your lathe after use. Dust and chips love to hide in nooks and crannies. Lubricate the moving parts too; they can get grumpy without oil! Think of it like giving your lathe a massage. Regular care helps avoid breakdowns and keeps everything spinning smoothly—like a dance party on the shop floor!

| Maintenance Task | Frequency |

|---|---|

| Clean the lathe | After each use |

| Lubricate moving parts | Weekly |

| Check for wear | Monthly |

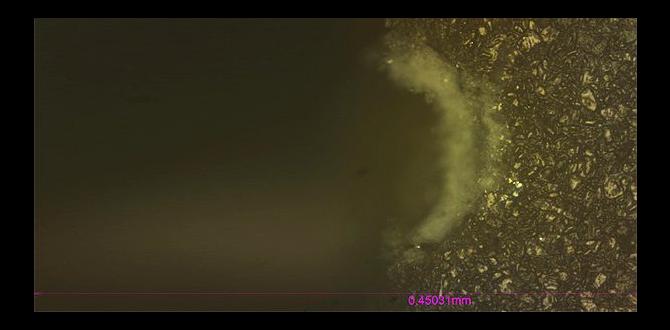

Common Issues and Troubleshooting in Lathe Workholding

Identifying and resolving common workholding problems. How to avoid workpiece distortion during machining.Sometimes, problems can arise in lathe workholding. It’s important to spot and fix these issues quickly. Common problems include:

- Improper clamping that leads to slipping.

- Uneven force causing workpiece distortion.

- Dirty or worn-out parts affecting performance.

How can I fix workholding problems?

To resolve workholding issues, regularly inspect clamps and fixtures. **Tightening or replacing parts can often solve the problem.** Ensuring smooth surfaces also helps maintain proper grip and reduces distortion.

Advanced Techniques for Efficient Machining

Use of advanced fixtures and automation. Tips for enhancing productivity through effective workholding setups.Improving machining can feel like a puzzle. Using advanced fixtures and automation helps pieces fit better. The right setup can save time and boost quality. Imagine a lathe that practically does the work for you! For top-notch workholding, focus on stability and alignment. You want the pieces to hug each other like best friends. Here’s a quick look at tips for increasing productivity:

| Tip | Description |

|---|---|

| Use Jigs and Fixtures | They hold workpieces securely. |

| Integrate Automation | Reduce human error and speed things up. |

| Optimize Tool Setup | Change tools quickly to save time. |

Remember, happy machinery makes for happy machinists!

Safety Considerations in Lathe Workholding and Maintenance

Importance of safety protocols during lathe operation. Protective gear and precautions to minimize risk.Safety is like the helmet for your head when using a lathe; you absolutely need it! Following safety protocols helps keep our fingers, eyes, and sanity intact. Imagine slipping on a banana peel during a spinning marathon; that’s how accidents happen! Always wear protective gear, like goggles, gloves, and earmuffs. They’re not just for show; they keep you safe from flying debris and loud noises. Remember, it’s better to be a little silly than to be hurt!

| Protective Gear | Purpose |

|---|---|

| Goggles | Keep your eyes safe from flying bits |

| Gloves | Protect your hands while holding materials |

| Earmuffs | Guard against loud machine sounds |

To keep risks low, always check your lathe before use. A little maintenance goes a long way. Think of it like brushing your teeth; you wouldn’t skip it, right? Regular checks save you from surprises that are far less fun!

Resources for Further Learning and Improvement

Recommended books, courses, and online resources. Communities and forums for lathe enthusiasts and professionals.Learning never stops, especially in lathe workholding. Many resources can help you grow your skills. Here are some great options:

- Books: Look for titles like “Lathework: A Complete Guide to Mastering Your Lathe” and “The Metal Lathe.

- Online Courses: Websites like Udemy and Coursera offer courses on lathe techniques.

- Communities: Join forums like The Garage Journal or Reddit’s r/metalworking for advice and help.

These resources make learning fun and easy!

What are the best online resources for lathe work?

Check out YouTube tutorials and websites like Instructables for free guides. These resources cover many topics in lathe work.

Conclusion

In conclusion, lathe workholding and metal lathe maintenance are essential for great results. Proper workholding secures your materials, ensuring accuracy. Regular maintenance keeps your lathe running smoothly and safely. Remember to clean your tools and check for wear. You can always find more tips online to improve your skills. Let’s keep learning and making amazing projects together!FAQs

Certainly! Here Are Five Questions Related To Lathe Workholding And Metal Lathe Maintenance:Sure! Here are five questions about using a lathe and taking care of it. 1. What is a lathe? A lathe is a machine that shapes metal or wood by spinning it. 2. How do we hold pieces on the lathe? We can use special clamps or chucks to hold the pieces tightly. 3. Why is maintenance important? Keeping the lathe clean and oiled helps it work better and last longer. 4. How often should we check our lathe? We should check it every time we use it to make sure everything is safe. 5. What tools do we need for maintenance? We need oil, cleaning cloths, and sometimes a wrench to tighten parts. Let me know if you have more questions!

Sure! Please provide the question you would like me to answer.

What Are The Most Common Types Of Workholding Methods Used In Metal Lathe Operations, And How Do They Affect Machining Accuracy?In metal lathe work, we often use three main types of workholding methods: chucks, collets, and faceplates. A chuck holds the piece tightly and can spin it easily. Collets fit the object snugly for better control. Faceplates help secure larger pieces. Using the right method keeps our work accurate, so we make better parts!

How Often Should Maintenance Checks Be Performed On A Metal Lathe To Ensure Optimal Performance And Longevity?You should check your metal lathe every month. This helps keep it running well. If you use it a lot, check it more often. Always look for any wear and tear. This way, your lathe will last a long time!

What Are Some Best Practices For Setting Up Workpieces In A Lathe To Minimize Vibrations And Ensure Better Surface Finish?To set up workpieces in a lathe, first, make sure they are held tightly. You can use a chuck or a faceplate to secure the piece well. Keep the workpiece balanced so it spins evenly. Check that your cutting tool is sharp, too. Finally, use the right speed for your material to get a smooth finish.

What Are The Signs Of Wear Or Damage In Lathe Workholding Equipment, And How Can These Be Addressed Effectively?You can see signs of wear or damage in lathe workholding equipment by looking for cracks, rust, or loose parts. If you notice these things, it’s important to fix them right away. You can clean rust off with a scrub and replace loose parts. Always check the equipment before you use it to keep everything safe and working well.

How Can Proper Lubrication And Cleaning Of A Metal Lathe Contribute To Its Overall Efficiency And Maintenance Schedule?Keeping a metal lathe clean and well-oiled helps it work better. When we clean it, we remove dirt that can cause problems. Lubrication, or putting oil in the right places, keeps the moving parts from wearing out. This means our lathe can last longer and we can use it more often without issues. A good maintenance schedule helps us remember to clean and oil it regularly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Lathe Workholding And Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about using a lathe and taking care of it. 1. What is a lathe? A lathe is a machine that shapes metal or wood by spinning it. 2. How do we hold pieces on the lathe? We can use special clamps or chucks to hold the pieces tightly. 3. Why is maintenance important? Keeping the lathe clean and oiled helps it work better and last longer. 4. How often should we check our lathe? We should check it every time we use it to make sure everything is safe. 5. What tools do we need for maintenance? We need oil, cleaning cloths, and sometimes a wrench to tighten parts. Let me know if you have more questions!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Workholding Methods Used In Metal Lathe Operations, And How Do They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe work, we often use three main types of workholding methods: chucks, collets, and faceplates. A chuck holds the piece tightly and can spin it easily. Collets fit the object snugly for better control. Faceplates help secure larger pieces. Using the right method keeps our work accurate, so we make better parts!”}},{“@type”: “Question”,”name”: “How Often Should Maintenance Checks Be Performed On A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your metal lathe every month. This helps keep it running well. If you use it a lot, check it more often. Always look for any wear and tear. This way, your lathe will last a long time!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Setting Up Workpieces In A Lathe To Minimize Vibrations And Ensure Better Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up workpieces in a lathe, first, make sure they are held tightly. You can use a chuck or a faceplate to secure the piece well. Keep the workpiece balanced so it spins evenly. Check that your cutting tool is sharp, too. Finally, use the right speed for your material to get a smooth finish.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Wear Or Damage In Lathe Workholding Equipment, And How Can These Be Addressed Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can see signs of wear or damage in lathe workholding equipment by looking for cracks, rust, or loose parts. If you notice these things, it’s important to fix them right away. You can clean rust off with a scrub and replace loose parts. Always check the equipment before you use it to keep everything safe and working well.”}},{“@type”: “Question”,”name”: “How Can Proper Lubrication And Cleaning Of A Metal Lathe Contribute To Its Overall Efficiency And Maintenance Schedule?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Keeping a metal lathe clean and well-oiled helps it work better. When we clean it, we remove dirt that can cause problems. Lubrication, or putting oil in the right places, keeps the moving parts from wearing out. This means our lathe can last longer and we can use it more often without issues. A good maintenance schedule helps us remember to clean and oil it regularly.”}}]}