Have you ever wondered how metal pieces are shaped and held in place during machining? The answer often lies in something called lathe workholding. A metal lathe is a fascinating tool. It helps craftsmen turn raw metal into precise parts for many uses. But to make this happen, the workholding method is crucial.

Imagine trying to carve a piece of wood without it being held still. Frustrating, right? Similarly, on a lathe, the way you secure the metal matters a lot. The saddle is a key part of this setup. It helps in positioning and holding the workpiece firmly as it spins. Without a good saddle, your project can go very wrong.

Did you know that even small mistakes can lead to big problems when working with metal? Getting the workholding right can save time and materials. In this article, we will explore different ways to use lathe workholding. Each method can change how easily you shape your metal projects.

Ready to dive into the world of lathe workholding? Let’s unlock the secrets of the metal lathe saddle together!

Effective Lathe Workholding Techniques For Metal Lathe Saddle

Understanding Lathe Workholding: Metal Lathe Saddle

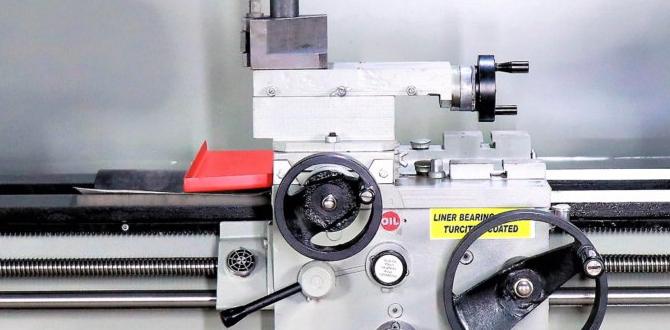

What holds your workpiece in place while using a lathe? It’s called a metal lathe saddle, and it’s vital for precision. The saddle supports the tool carriage and helps move it smoothly along the bed. Imagine trying to carve a statue with your hands but you have to hold the stone at the same time! A lathe saddle does just that – keeps your work stable. Choosing the right saddle ensures better results and less frustration. Curious about how it can improve your projects?What is a Metal Lathe Saddle?

Definition and function of a metal lathe saddle. Importance in machining operations.A metal lathe saddle is a crucial part of a metal lathe machine. It holds the workpiece securely in place during machining. This helps ensure accurate cuts. Without it, the machining process could lead to mistakes.

The saddle supports the tool and helps the lathe move smoothly. It plays a big role in creating precise shapes and sizes. This makes it important for producing everything from simple screws to complex parts.

- Holds Workpieces: Keeps pieces steady for accurate cuts.

- Smooth Movement: Allows for easy tool adjustments.

- Precision: Essential for high-quality machining results.

How does a metal lathe saddle work?

A metal lathe saddle works by supporting the workpiece while the lathe spins it. It allows the cutting tool to move along the piece, shaping it accurately.

Key Features of Metal Lathe Saddles

Material construction and durability. Design elements that enhance precision and stability.Understanding the importance of metal lathe saddles helps improve any lathe project. These components are made from strong materials, like cast iron or steel, offering great durability. The sturdy design enhances precision and stability during lathe work. Why is that important? Accurate cuts and smooth finishes depend on a secure positioning of the workpiece.

- Durable materials resist wear and tear.

- Precision designs keep the workpiece steady.

- Adjustable features allow for customized settings.

What materials are used for lathe saddles?

Most lathe saddles use cast iron or steel due to their strength. These materials help the saddle last longer and perform better.

Workholding Techniques with Metal Lathe Saddles

Clamping methods for secure workpiece positioning. Use of vises and fixtures in conjunction with saddles.Effective workholding is key when using a metal lathe saddle. Clamping methods like collet chucks or band clamps help keep your workpiece secure. Imagine trying to cut a slippery watermelon without holding it tight—chaos! Vises and fixtures can be great companions too. They act like a supportive friend, keeping your piece steady while you work. Here’s a quick table for better understanding:

| Clamping Method | Description |

|---|---|

| Collet Chucks | Tightens around the workpiece evenly for a snug fit. |

| Band Clamps | Great for odd shapes, wrapping them tightly. |

| Vises | Holds flat or cylindrical items securely. |

By using these techniques, you ensure precise cuts and avoid mistakes. Remember, a well-held workpiece is a happy workpiece!

Best Practices for Lathe Workholding

Guidelines to ensure safety and precision. Maintenance tips for extending saddle lifespan.To work safely and accurately with your lathe, follow these simple rules. First, always wear safety goggles. No one wants metal shavings dancing in their eyes! Next, ensure your workpiece is secured tightly using a workholding device. This keeps everything steady as you spin. Regularly check your lathe’s saddle for wear. A well-maintained saddle can last for years, saving you time and money. Here’s a quick maintenance table for you:

| Maintenance Tip | Frequency |

|---|---|

| Clean chips and debris | After each use |

| Lubricate moving parts | Weekly |

| Check for wear | Monthly |

Following these best practices keeps your lathe happy and working like a charm. Happy turning!

Common Issues and Troubleshooting

Identifying and resolving workholding inaccuracies. Solutions for saddle wear and tear.Many lathes can be tricky, just like trying to eat spaghetti with a spoon! One common problem is workholding inaccuracies. These can make your part wobbly or uneven. To fix this, check your clamps and fixtures. Make sure everything is snug. Saddle wear and tear is another issue. You can see this if your lathe isn’t smooth anymore. Regular maintenance is key! Replace worn parts quickly for best results.

| Issue | Solution |

|---|---|

| Workholding inaccuracies | Check clamps and tightness |

| Saddle wear | Regular maintenance and replacement |

Remember, ignoring these problems is like letting a clown hold your ice cream. It’s not good! Stay vigilant and keep your lathe in top shape.

Advancements in Lathe Saddle Technology

Current innovations in design and materials. Impact of technology on machining efficiency.Lathe saddle technology is taking big leaps forward! New designs focus on lighter materials that make the saddle easier to handle. This is like replacing your heavy backpack with a cool, feather-light one! Because of these changes, machining efficiency has also improved. For instance, faster setups mean more time making cool things and less time just waiting. Here’s a quick look at some advancements:

| Innovation | Benefit |

|---|---|

| Lightweight Materials | Easy to manage |

| Smart Designs | Better accuracy |

| Automation Features | Increased production speed |

With tech moving so fast, you might get dizzy! But that’s a good thing for all the makers out there.

Comparative Analysis: Metal Lathe Saddle vs. Alternative Workholding Methods

Advantages of using saddles over other methods. Scenarios where alternatives may be more effective.Using saddles for metal lathe workholding is often like having a trusty sidekick—ready to hold your work piece steady so you can focus on making magical things! Saddles are known for their grip and stability, which helps avoid those spooky slips during cutting. However, in some tricky scenarios, alternatives like vices or clamps might be better. For example, if you’re working with oddly shaped pieces or different materials, a good vice might save the day. Check out the quick comparison below!

| Method | Advantages | Best Scenario |

|---|---|---|

| Saddle | Stability, ease of use | Standard shapes |

| Vice | Versatile, strong grip | Odd shapes |

| Clamp | Portable, flexible | Light materials |

So, while saddles shine in many situations, don’t forget your other tools. They can be just as handy in a pinch—and might just save your day (or your project) with a smile!

Conclusion

In summary, lathe workholding with a metal lathe saddle is essential for accurate machining. It keeps your workpiece stable and secure during cutting. By understanding how to use it properly, you can improve your projects. We encourage you to practice using different saddles and explore more resources on lathe techniques. Happy machining!FAQs

Sure! Here Are Five Questions Related To Lathe Workholding, Specifically Focusing On The Metal Lathe Saddle:Sure! The metal lathe saddle is an important part that holds the tool. It moves back and forth to help shape metal pieces. You can adjust it to change how deep the tool cuts. This helps in making different designs and sizes. Always keep it clean so it works well!

Sure! Please provide the question you want me to answer.

What Are The Key Components Of A Metal Lathe Saddle, And How Do They Contribute To Effective Workholding During Machining Operations?A metal lathe saddle has important parts that help hold the metal while we work on it. These parts include the tailstock, headstock, and cross slide. The tailstock supports one end of the metal, while the headstock drives the other end. The cross slide lets us move tools to shape the metal. Together, they keep everything steady and safe during cutting.

How Do Different Types Of Workholding Devices, Such As Chucks And Vises, Interact With The Saddle To Secure Workpieces On A Metal Lathe?Chucks and vises help hold the metal pieces tight on a lathe. The saddle is a part that moves back and forth. When you use a chuck, it grips the workpiece firmly. Vises do the same by squeezing the metal. This keeps the piece safe while we work on it.

What Factors Should Be Considered When Selecting A Workholding Method For Specific Materials And Geometries In Lathe Operations?When choosing a way to hold a part on a lathe, think about the material and shape. Some materials, like soft metals, need a gentle grip. Harder materials may need a stronger hold. You should also look at the shape of the part. Simple shapes are easier to hold, while complex shapes might need special tools. Always make sure the part is stable while you work!

How Can Improper Alignment Of The Metal Lathe Saddle Affect Machining Accuracy And Part Quality During Turning Operations?If the metal lathe saddle isn’t lined up correctly, it can cause problems. The part you’re making can be wobbly or uneven. This means it won’t fit well or work properly. You want everything straight so your parts are strong and look good. Always check the alignment before you start to avoid mistakes.

What Are Some Best Practices For Maintaining And Adjusting The Metal Lathe Saddle To Ensure Optimal Workholding Performance Over Time?To keep the metal lathe saddle working well, you should check it often. Clean it regularly to remove dust and dirt. Make sure all the parts are tight and not loose. Adjust the saddle so it moves smoothly, without sticking. Finally, use lubricant to keep everything running easily and prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Workholding, Specifically Focusing On The Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The metal lathe saddle is an important part that holds the tool. It moves back and forth to help shape metal pieces. You can adjust it to change how deep the tool cuts. This helps in making different designs and sizes. Always keep it clean so it works well!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Saddle, And How Do They Contribute To Effective Workholding During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe saddle has important parts that help hold the metal while we work on it. These parts include the tailstock, headstock, and cross slide. The tailstock supports one end of the metal, while the headstock drives the other end. The cross slide lets us move tools to shape the metal. Together, they keep everything steady and safe during cutting.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Workholding Devices, Such As Chucks And Vises, Interact With The Saddle To Secure Workpieces On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chucks and vises help hold the metal pieces tight on a lathe. The saddle is a part that moves back and forth. When you use a chuck, it grips the workpiece firmly. Vises do the same by squeezing the metal. This keeps the piece safe while we work on it.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Workholding Method For Specific Materials And Geometries In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a way to hold a part on a lathe, think about the material and shape. Some materials, like soft metals, need a gentle grip. Harder materials may need a stronger hold. You should also look at the shape of the part. Simple shapes are easier to hold, while complex shapes might need special tools. Always make sure the part is stable while you work!”}},{“@type”: “Question”,”name”: “How Can Improper Alignment Of The Metal Lathe Saddle Affect Machining Accuracy And Part Quality During Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the metal lathe saddle isn’t lined up correctly, it can cause problems. The part you’re making can be wobbly or uneven. This means it won’t fit well or work properly. You want everything straight so your parts are strong and look good. Always check the alignment before you start to avoid mistakes.”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Maintaining And Adjusting The Metal Lathe Saddle To Ensure Optimal Workholding Performance Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the metal lathe saddle working well, you should check it often. Clean it regularly to remove dust and dirt. Make sure all the parts are tight and not loose. Adjust the saddle so it moves smoothly, without sticking. Finally, use lubricant to keep everything running easily and prevent rust.”}}]}