Have you ever wondered how metal parts are made? Many machine shops have a special tool called a lathe. A lathe can shape metal into precise pieces. But to do this correctly, it needs solid workholding methods.

One important part of this is the lathe spindle. The spindle holds the metal securely while it spins. This is crucial for accuracy. If the metal moves, it can ruin the whole project.

Imagine building your own robot. Each piece needs to fit just right. If the parts are too loose or wobbly, the robot won’t work. That’s why understanding lathe workholding is so important.

Fun fact: Did you know that lathes date back to ancient Egypt? They have helped people create amazing things for thousands of years. Today, they are still as valuable as ever!

In this article, we will explore the best techniques for lathe workholding. You’ll learn how to use a lathe spindle effectively. Let’s dive in and discover the fascinating world of metalworking!

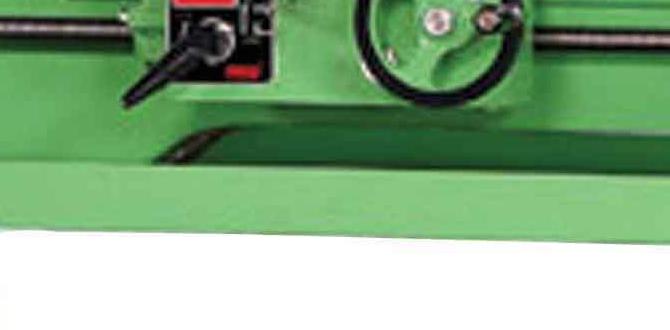

Lathe Workholding: Essential Metal Lathe Spindle Techniques

Lathe Workholding Metal Lathe Spindle

Understanding lathe workholding is crucial for anyone using a metal lathe. A spindle securely holds the workpiece, allowing for precise cutting and shaping. Did you know that the proper spindle setup can significantly improve your project’s accuracy? It’s fascinating! Different spindles and fixtures can hold various shapes and sizes, each perfect for specific tasks. Choosing the right one means better results and easier work. Discover the importance of spindles in lathe operations!Understanding Metal Lathe Spindles

Definition and function of metal lathe spindles. Types of spindles used in various metalworking applications.A metal lathe spindle is a crucial part of a lathe machine. It holds and rotates the workpiece as it is shaped. Spindles come in different types, each designed for specific tasks in metalworking. Here are a few common types:

- Fixed spindle: Remains in one place to support the rotating tool.

- Live spindle: Moves while the tool shapes materials.

- Hollow spindle: Allows for long pieces to pass through.

Each type helps achieve accurate cuts and designs in metal. Understanding these differences can improve your metalworking skills.

What is the function of a metal lathe spindle?

A metal lathe spindle holds the workpiece and makes it spin. This spinning helps shape and cut the metal. It’s essential for precise work in the lathe process.

Importance of Workholding in Lathe Operations

Explanation of workholding and its role in precision machining. Common challenges faced without proper workholding techniques.Workholding is key for using a lathe effectively. It keeps the metal piece steady while cutting. This is important for precision machining. Without good workholding, problems arise. Parts may wobble or shift, leading to mistakes. Here are some common issues faced:

- Inaccurate cuts

- Damaged materials

- Increased waste

Using proper workholding techniques ensures each piece is just right. Remember, precision leads to quality!

Why is proper workholding necessary?

Proper workholding is vital to avoid errors and enhance safety. It helps create smooth, accurate parts without wasting materials or time.

Choosing the Right Spindle for Your Lathe

Factors to consider when selecting a spindle (material, size, etc.). How spindle choice affects workholding efficiency and accuracy.Picking the right spindle for your lathe is like choosing the right shoes for a race. You want something that fits well and *won’t* trip you up! First, consider the material—steel is strong, but aluminum can be lighter and easier to handle. Size matters too; if it’s too big or small, your workholding could go sideways—literally! A suitable spindle enhances *efficiency* and accuracy, making sure your projects are smooth and precise. Remember, a good spindle towers above bad workholding like a superhero in shiny spandex!

| Factor | Details |

|---|---|

| Material | Steel is durable; aluminum can be light. |

| Size | Must fit your lathe perfectly for best results. |

| Efficiency | A good choice means better performance. |

| Accuracy | A proper spindle helps avoid mistakes. |

Techniques for Effective Workholding on Metal Lathes

Proven techniques for securing workpieces securely. Tips for improving accuracy and reducing vibration during machining.To hold your workpieces tight on a metal lathe, try using three-jaw chucks. They grip round shapes easily and make you feel like a pro! For flat pieces, faceplates do wonders, holding those stubborn shapes in place. Don’t forget about adding a little padding to reduce vibrations. Stable setups lead to precise cuts. Speaking of accuracy, a well-balanced setup can cut vibration by over 50%—that’s like magic! Want to be a lathe master? Here are some tips:

| Technique | Benefit |

|---|---|

| Use three-jaw chucks | Easy grip for round pieces |

| Employ faceplates | Great for flat workpieces |

| Add padding | Reduces vibration |

Your lathe journey can be fun, and following these tips can lead to some neat creations!

Maintaining Your Lathe Spindle for Optimal Performance

Best practices for spindle maintenance and care. Signs of wear and how to address spindle issues.For a smooth-running lathe spindle, regular maintenance is key. Follow these best practices:

- Clean the spindle often to remove grime and dust.

- Check for tightness in the connections.

- Lubricate moving parts as needed.

- Inspect for wear or damage regularly.

Signs of trouble can include strange noises or vibrations. If you hear a grinding sound, it’s time to act. Look for wear on bearings and replace them if necessary. Addressing these issues early can prevent larger problems down the road.

What are common signs of spindle wear?

Common signs include

1. Unusual noises

2. Vibrations

3. Inconsistent machining quality

Check for any of these to keep your lathe in peak condition!

Common Problems and Solutions in Lathe Workholding

Identification of typical workholding issues. Practical solutions and troubleshooting tips for each problem.Working with lathes can feel like a dance. But sometimes, that dance steps on a toe! Common issues include parts slipping or wobbling. This can lead to messy work and frustration. Don’t worry! Solutions abound! Check if the chuck is tight. Use the right grip for different materials. If there’s still wobble, adjust your spindle speed. Here’s a handy table for quick fixes:

| Issue | Solution |

|---|---|

| Part slips | Tighten the chuck |

| Wobbling | Adjust spindle speed |

| Inconsistent finishes | Check tool alignment |

Keep these tips in your toolbox, and you’ll be a lathe superstar in no time! Remember, every mistake is just a chance to learn and laugh.

Conclusion

In conclusion, understanding lathe workholding and the metal lathe spindle is crucial for successful projects. You need the right tools to keep your workpieces secure. Experiment with different methods to find what works best for you. Keep learning about lathe techniques, and practice often for the best results. Ready to dive deeper? Grab a book or watch some tutorials!FAQs

What Are Some Common Workholding Methods Used On A Metal Lathe Spindle, And How Do They Affect Precision And Stability?You can hold metal pieces in a lathe using methods like chucks and collets. A chuck has jaws that grip the metal, while a collet is a sleeve that holds smaller pieces tightly. Both help keep the metal steady while the lathe spins it. When the piece is secure, it cuts more accurately and stays in place, which is important for good work.

How Do Different Types Of Chucks (E.G., Three-Jaw Vs. Four-Jaw) Influence The Workholding Capabilities Of A Lathe Spindle?Different types of chucks hold things in place when you use a lathe. A three-jaw chuck has three grips that hold round shapes tightly. This is great for most projects. A four-jaw chuck has four grips. It can hold odd shapes better, but it takes more time to set up. Each type helps you work with different materials in the best way.

What Safety Precautions Should Be Taken When Setting Up Workholding Devices On A Metal Lathe Spindle?When setting up workholding devices on a metal lathe spindle, always wear safety goggles to protect your eyes. Make sure the lathe is turned off before you start. Check that the workholding device is tightly secured so it won’t move. Keep your hands away from moving parts. Finally, clean up any tools or debris to avoid accidents.

How Do Factors Such As Part Size And Shape Dictate The Choice Of Workholding Solution On A Lathe Spindle?Part size and shape help us decide how to hold a piece when using a lathe. If the piece is small and round, we might use a special clamp called a chuck. For bigger pieces or odd shapes, a different method might be better. The right workholding solution keeps the piece steady while we work on it. This helps us make sure everything comes out just right!

What Are The Advantages And Disadvantages Of Using Collets Versus Chucks For Workholding In Lathe Applications?Collets hold workpieces tightly and are easy to change. They are great for small parts and provide good precision. However, they are not as strong for larger items. Chucks can hold bigger and heavier pieces, but they take longer to set up. So, choose collets for smaller work and chucks for larger jobs.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are Some Common Workholding Methods Used On A Metal Lathe Spindle, And How Do They Affect Precision And Stability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can hold metal pieces in a lathe using methods like chucks and collets. A chuck has jaws that grip the metal, while a collet is a sleeve that holds smaller pieces tightly. Both help keep the metal steady while the lathe spins it. When the piece is secure, it cuts more accurately and stays in place, which is important for good work.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Chucks (E.G., Three-Jaw Vs. Four-Jaw) Influence The Workholding Capabilities Of A Lathe Spindle? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of chucks hold things in place when you use a lathe. A three-jaw chuck has three grips that hold round shapes tightly. This is great for most projects. A four-jaw chuck has four grips. It can hold odd shapes better, but it takes more time to set up. Each type helps you work with different materials in the best way.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Setting Up Workholding Devices On A Metal Lathe Spindle? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up workholding devices on a metal lathe spindle, always wear safety goggles to protect your eyes. Make sure the lathe is turned off before you start. Check that the workholding device is tightly secured so it won’t move. Keep your hands away from moving parts. Finally, clean up any tools or debris to avoid accidents.”}},{“@type”: “Question”,”name”: “How Do Factors Such As Part Size And Shape Dictate The Choice Of Workholding Solution On A Lathe Spindle? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Part size and shape help us decide how to hold a piece when using a lathe. If the piece is small and round, we might use a special clamp called a chuck. For bigger pieces or odd shapes, a different method might be better. The right workholding solution keeps the piece steady while we work on it. This helps us make sure everything comes out just right!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using Collets Versus Chucks For Workholding In Lathe Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collets hold workpieces tightly and are easy to change. They are great for small parts and provide good precision. However, they are not as strong for larger items. Chucks can hold bigger and heavier pieces, but they take longer to set up. So, choose collets for smaller work and chucks for larger jobs.”}}]}