Have you ever wondered how metal parts are shaped perfectly? Lathe workholding is the key! It helps secure materials in place while cutting. Using the right metal lathe tools makes all the difference. Think about how frustrating it would be if your project kept slipping or moving. Lathe workholding prevents that. It keeps everything steady and secure.

Here’s a fun fact: the first lathe was created over 2,000 years ago! Back then, craftsmen used simple tools. Today, we have advanced metal lathe tools that make the job easier and faster. Imagine creating custom pieces just like the pros. With the right techniques, anyone can master lathe workholding!

In this article, we will explore various methods and tools you can use. Whether you’re a beginner or an expert, there is something for everyone. Let’s dive into the exciting world of lathe workholding!

Essential Lathe Workholding Techniques For Metal Lathe Tools

Understanding Lathe Workholding Metal Lathe Tools

Have you ever wondered how metal parts are shaped? Lathe workholding is crucial in this process. It keeps the metal piece steady while tools shape it into the desired form. Using the right metal lathe tools can greatly improve the quality of your work. Different tools serve various purposes, making tasks easier and more efficient. Whether you’re a hobbyist or a professional, knowing these basics will elevate your projects. Remember, the right setup makes all the difference!Types of Workholding Devices

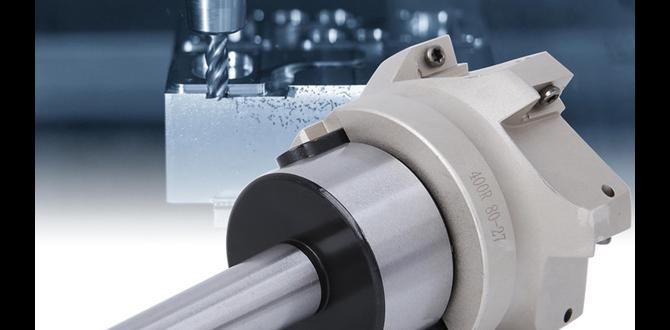

Description of chucks, faceplates, and collets. Comparison of fixed vs. adjustable workholding devices.If you work with metal lathes, you’ll meet some clever devices. Chucks hold round pieces snug like a bear hug, while faceplates are perfect for flat surfaces, making them as useful as a Swiss Army knife in your toolbox. Collets, on the other hand, are like magic rings that grip all sorts of shapes tight. Now, let’s chat about fixed and adjustable devices. Fixed ones are dependable but can’t budge, while adjustable ones are flexible, just like that stretchy pair of pants you wear after Thanksgiving! Check this out:

| Device Type | Description |

|---|---|

| Chucks | Holds round items securely. |

| Faceplates | Great for securing flat pieces. |

| Collets | Grips different shapes tightly. |

| Fixed | Stable but not adjustable. |

| Adjustable | Flexible and versatile. |

Selecting the Right Workholding Tool

Factors to consider when choosing workholding tools for your projects. How material type affects the choice of workholding devices.Choosing the right workholding tool is important for your projects. You’ll want to think about a few key factors:

- Material type: The material you’re working with affects your choice. For softer metals, you may need a different tool than for harder materials.

- Tool size: Make sure the tool fits your lathe and works with the size of your workpiece.

- Project goals: Understand what you want to achieve with your project. This helps narrow down the options.

Using the right tool makes your work easier and safer, allowing you to create better results!

How does material type affect workholding device choice?

The type of material you use guides your selection. For example, softer materials like aluminum may need clamps, while harder metals might need more sturdy grips. Think about how strong the workholding device must be for your material!

Setup Procedures for Lathe Workholding

Stepbystep guide to setting up workholding tools on a metal lathe. Best practices to ensure accurate and safe setup.Setting up workholding tools on a metal lathe is crucial for success. Start by choosing the right tool for your job. Carefully secure your workpiece. Make sure it is centered. This helps in getting even cuts. Always double-check your measurements. Here are some best practices:

- Always wear safety goggles.

- Keep your tools clean.

- Check machine settings before starting.

Following these steps can ensure safe and smooth lathe work.

How can I ensure accurate lathe setup?

To ensure accuracy, always verify the alignment of your workpiece and tool. Regular calibration of the lathe is also essential.

Improving Precision with Workholding Techniques

Techniques for enhancing precision and repeatability in lathe workholding. Importance of alignment and balancing when securing workpieces.To achieve top-notch precision in lathe work, effective workholding techniques are key. Proper alignment helps keep your workpiece steady, like keeping a cat from chasing a laser pointer. Balance is equally vital; an unbalanced piece can wobble more than a toddler in a bounce house! Ensuring secure holds leads to fewer mistakes and smoother cuts. Explore these main techniques below:

| Technique | Description |

|---|---|

| V-Blocks | Great for cylindrical pieces; they cradle them perfectly. |

| Chucks | These grab your workpiece and don’t let it go. Like a good hug! |

| Mandrels | Perfect for holding complex shapes with style. |

Remember, the better the hold, the better the outcome. As they say, “Measure twice, cut once.” Or maybe, “Secure well, cut like a pro!”

Maintenance and Care of Workholding Tools

Tips for maintaining and cleaning workholding devices. Common issues encountered and how to troubleshoot them.Keeping your workholding tools in good shape is important for smooth lathe work. Regular cleaning prevents dust and grime buildup. Here are some simple tips:

- Wipe tools with a soft cloth after each use.

- Check for rust and use oil to prevent it.

- Tighten any loose screws to ensure stability.

If you face issues, consider these common problems:

- Difficulty securing the workpiece: Check the clamps for damage.

- Uneven cuts: Make sure the tool is sharp and correctly aligned.

Remember, a few minutes of care today can save time and trouble tomorrow!

What is the best way to clean workholding tools?

The best way to clean them is to wipe them down with a soft cloth and occasional mild cleaner. This keeps tools working well and looking good!

How can I prevent rust on my tools?

To prevent rust, apply some machine oil to the metal parts regularly. This creates a barrier against moisture.

Innovations in Lathe Workholding

Latest technologies and advancements in workholding tools. How modern materials and designs improve lathe efficiency.In the world of lathe workholding, newcomers can be amazed by the latest tools making waves! New technology and smart designs are supercharged with modern materials, boosting lathe efficiency like never before. Imagine a superhero tool that holds your metal pieces tightly while you spin them around! More grip means less slip—goodbye, wobbly creations! Advanced clamps and magnetic holds are reshaping workspaces and saving time. Below is a glimpse of some exciting innovations:

| Innovation | Description |

|---|---|

| Quick Change Tool Holders | No more wasting time! Switch tools fast and get back to work. |

| Self-Centering Chucks | Holds workpieces like a gentle hug! Perfect alignment every time. |

| Magnetic Workholding | Strong as a superhero! Keeps metal parts in place without clamps. |

With these advancements, lathe work is a breeze. Who knew workholding could be this much fun?

Case Studies: Successful Workholding Solutions

Examples of industries leveraging advanced workholding systems. Analyzing the impact of effective workholding on production outcomes.Many industries are seeing big gains by using smart workholding systems. For example, automotive plants now hold parts tightly, reducing mistakes and speeding up production. These systems can boost efficiency by up to 30%, which is like a cheetah in a race! In a study, machine shops reported a drop in setup time thanks to their new tools, allowing them to spin more metal and a lot less waiting. Who knew holding things could be so powerful?

| Industry | Impact of Workholding |

|---|---|

| Automotive | 30% increase in efficiency |

| Aerospace | 25% reduction in errors |

| Machine Shops | 50% faster setup time |

Resources and Further Reading

Recommended books, articles, and online resources on lathe workholding. Professional organizations and forums for metalworking enthusiasts.Looking to dive deeper into lathe workholding? Check out some recommended books and online articles that turn the technical mumbo jumbo into fun reading! Websites like Woodworking for Beginners have great guides on metal lathe tools. Plus, many forums exist where metalworking enthusiasts share tips and tricks. Don’t miss out on joining communities like The Metalworking Forum and Machine Builders Facebook Group to talk shop with fellow fans!

| Resource Type | Resource Name |

|---|---|

| Book | Lathe Work: A Complete Guide |

| Article | Understanding Metal Lathe Tools |

| Forum | The Metalworking Forum |

Conclusion

In summary, understanding lathe workholding and metal lathe tools is essential for successful machining projects. These tools help secure materials effectively, ensuring accurate shaping. You should explore different workholding methods and tools to find what works best for you. By doing so, you’ll improve your skills and projects. Keep learning and practicing to become more confident in your lathe work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Tools:Sure! When using a lathe, you need to hold the metal piece steady. We use tools called workholding devices, like chucks or collets, to do this. Chucks grip the metal tightly, so it doesn’t move while we work on it. This helps us make the piece smooth and the right shape. With the right tools, we can create many cool things!

Sure! Please provide the question you want me to answer.

What Are The Most Common Types Of Chucks Used For Workholding On A Metal Lathe, And How Do They Differ In Functionality?The most common types of chucks on a metal lathe are three-jaw chucks, four-jaw chucks, and collet chucks. Three-jaw chucks grip round parts evenly as they close together. Four-jaw chucks can hold square or oddly shaped pieces more firmly because you can adjust each jaw separately. Collet chucks hold smaller round pieces tightly and help with smaller jobs. Each type is good for different shapes and sizes of materials.

How Can You Ensure That A Workpiece Is Properly Aligned And Secured In A Lathe To Achieve Precision Machining?To make sure a workpiece is lined up and held tight in a lathe, start by checking the centers. Place the workpiece in the middle of the machine. Use clamps or a chuck to hold it securely. Turn the machine slowly and watch for any wobbles. Adjust as needed until it spins evenly. This helps you make precise cuts.

What Are The Advantages And Disadvantages Of Using Collets Versus Chucks For Holding Cylindrical Workpieces On A Lathe?Using collets to hold round pieces is great because they grip tightly and keep things very straight. You can quickly change workpieces with collets too. However, collets can be more expensive and only fit specific sizes. Chucks are more flexible. They can hold different sizes and shapes, which is useful. But they might not hold as tightly as collets, so they could wobble a bit.

How Do Fixture Plates And Tooling Systems Enhance The Versatility And Efficiency Of Workholding Setups In Metal Lathe Operations?Fixture plates and tooling systems help you hold metal pieces better on a lathe. They let you quickly swap out different tools and parts. This saves time when you change jobs. Because they’re flexible, you can make many different things. Overall, they make working faster and easier!

What Safety Precautions Should You Take When Working With Different Types Of Lathe Workholding Devices To Prevent Accidents?When using lathes, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing. Make sure the workholding device is secure before you start. Always keep your hands away from moving parts. If you feel unsure, ask for help!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a lathe, you need to hold the metal piece steady. We use tools called workholding devices, like chucks or collets, to do this. Chucks grip the metal tightly, so it doesn’t move while we work on it. This helps us make the piece smooth and the right shape. With the right tools, we can create many cool things!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Types Of Chucks Used For Workholding On A Metal Lathe, And How Do They Differ In Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common types of chucks on a metal lathe are three-jaw chucks, four-jaw chucks, and collet chucks. Three-jaw chucks grip round parts evenly as they close together. Four-jaw chucks can hold square or oddly shaped pieces more firmly because you can adjust each jaw separately. Collet chucks hold smaller round pieces tightly and help with smaller jobs. Each type is good for different shapes and sizes of materials.”}},{“@type”: “Question”,”name”: “How Can You Ensure That A Workpiece Is Properly Aligned And Secured In A Lathe To Achieve Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure a workpiece is lined up and held tight in a lathe, start by checking the centers. Place the workpiece in the middle of the machine. Use clamps or a chuck to hold it securely. Turn the machine slowly and watch for any wobbles. Adjust as needed until it spins evenly. This helps you make precise cuts.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using Collets Versus Chucks For Holding Cylindrical Workpieces On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using collets to hold round pieces is great because they grip tightly and keep things very straight. You can quickly change workpieces with collets too. However, collets can be more expensive and only fit specific sizes. Chucks are more flexible. They can hold different sizes and shapes, which is useful. But they might not hold as tightly as collets, so they could wobble a bit.”}},{“@type”: “Question”,”name”: “How Do Fixture Plates And Tooling Systems Enhance The Versatility And Efficiency Of Workholding Setups In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Fixture plates and tooling systems help you hold metal pieces better on a lathe. They let you quickly swap out different tools and parts. This saves time when you change jobs. Because they’re flexible, you can make many different things. Overall, they make working faster and easier!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should You Take When Working With Different Types Of Lathe Workholding Devices To Prevent Accidents?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using lathes, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing. Make sure the workholding device is secure before you start. Always keep your hands away from moving parts. If you feel unsure, ask for help!”}}]}